A three-dimensional automatic design method and system for aircraft cables

An automatic design and aircraft technology, applied in the fields of instrument, calculation, electrical digital data processing, etc., can solve the problems of incomplete cable structure data, complex cabin structure model, large amount of information, etc., to achieve 3D automatic design, fast 3D The effect of automated design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

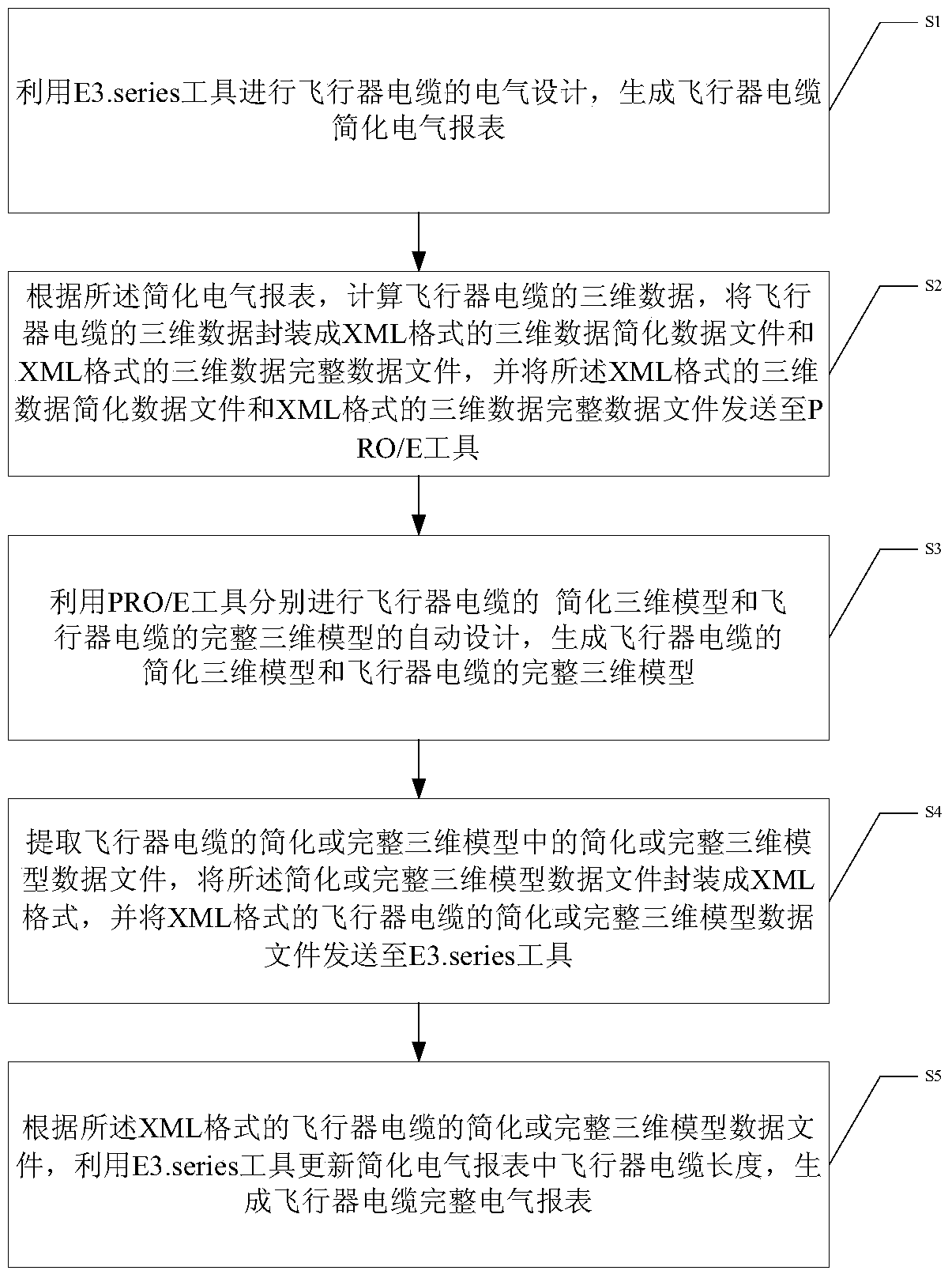

[0052] The three-dimensional automatic design method of the aircraft cable provided by the present embodiment includes the following steps:

[0053] Step1. Use the E3.series tool to carry out the electrical design of the aircraft cable, that is, to carry out the electrical drawing and report design of the aircraft cable, and generate a simplified electrical report for the aircraft cable;

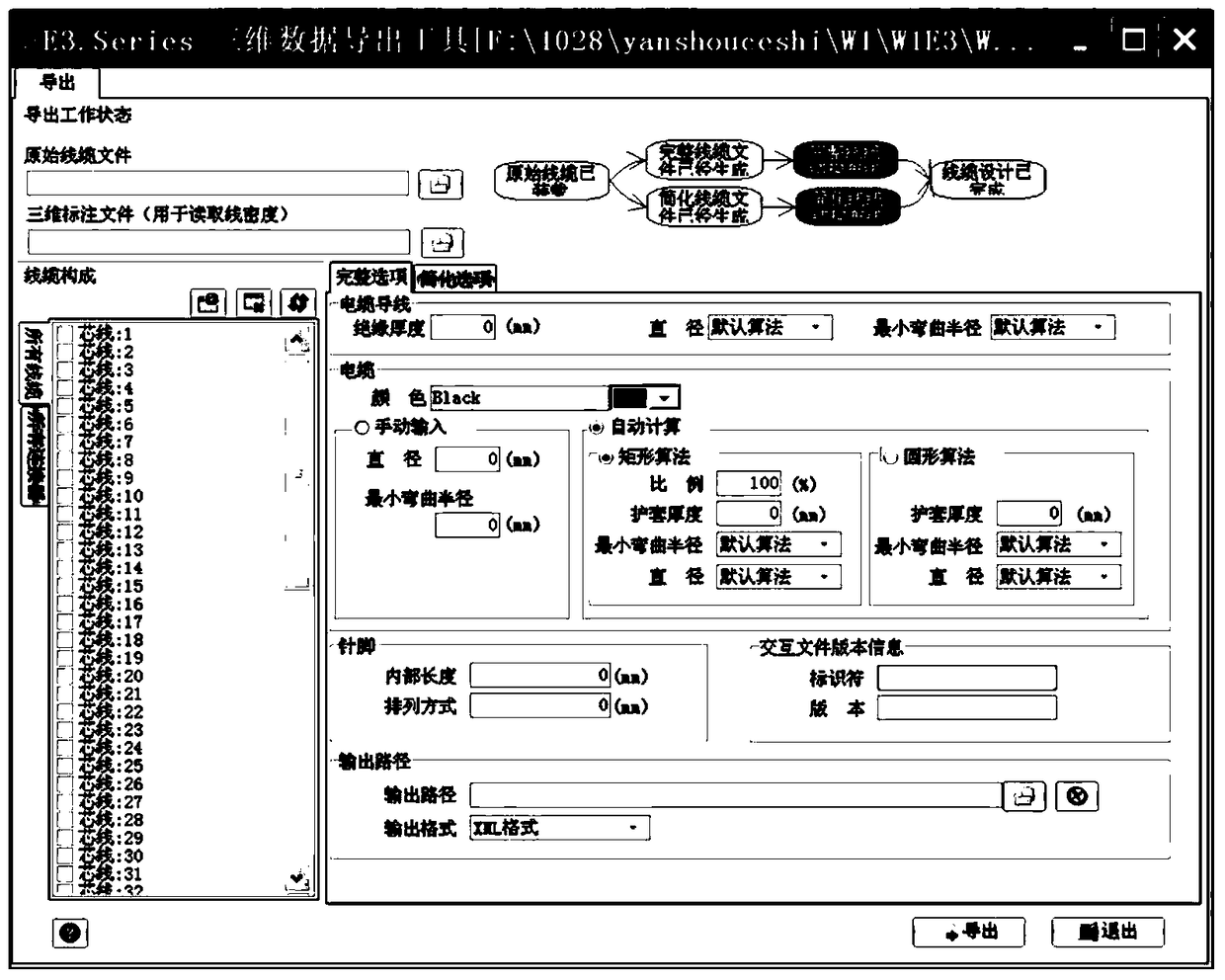

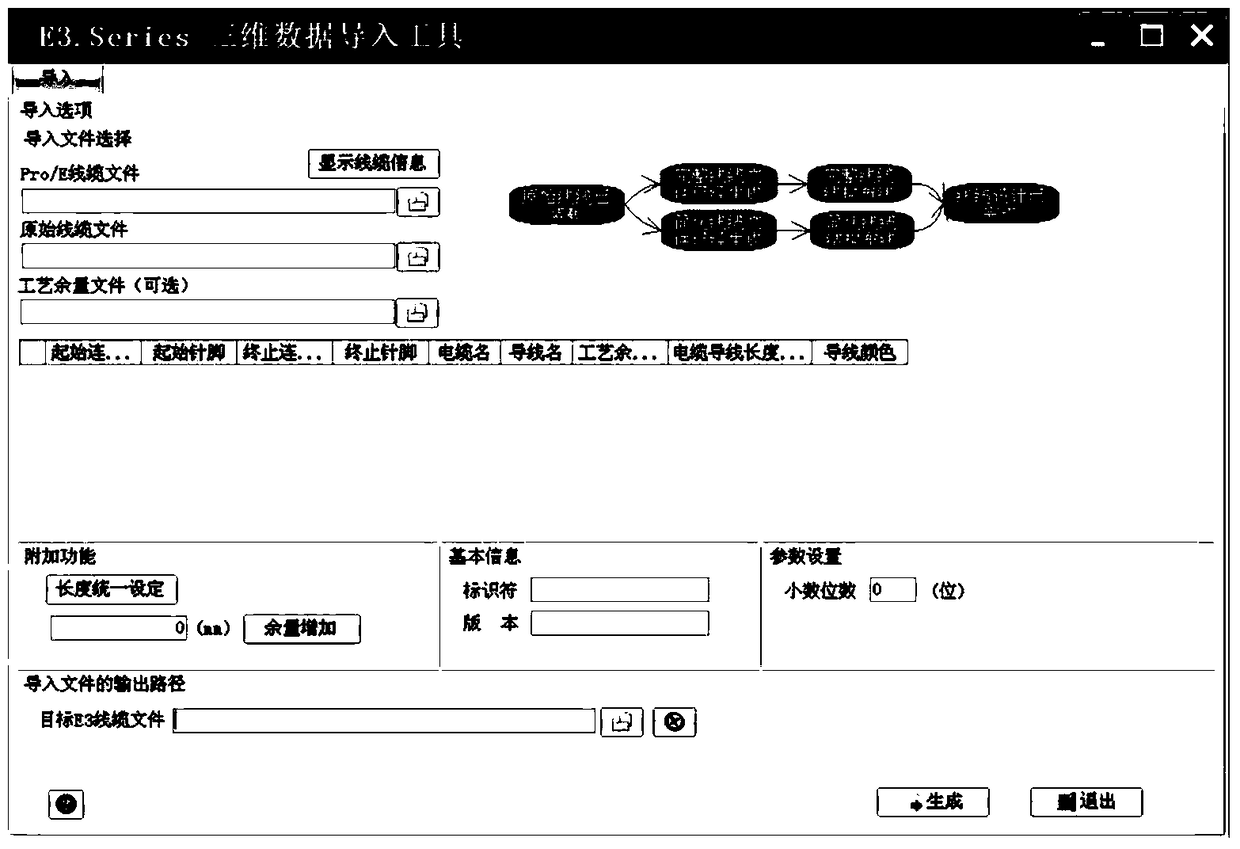

[0054] Step2. According to the simplified electrical report, calculate the three-dimensional data of the aircraft cable, encapsulate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com