Electric winding device with replaceable platen

A pressure plate, electric technology, applied in projection devices, door/window protection devices, optics, etc., to avoid direct scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

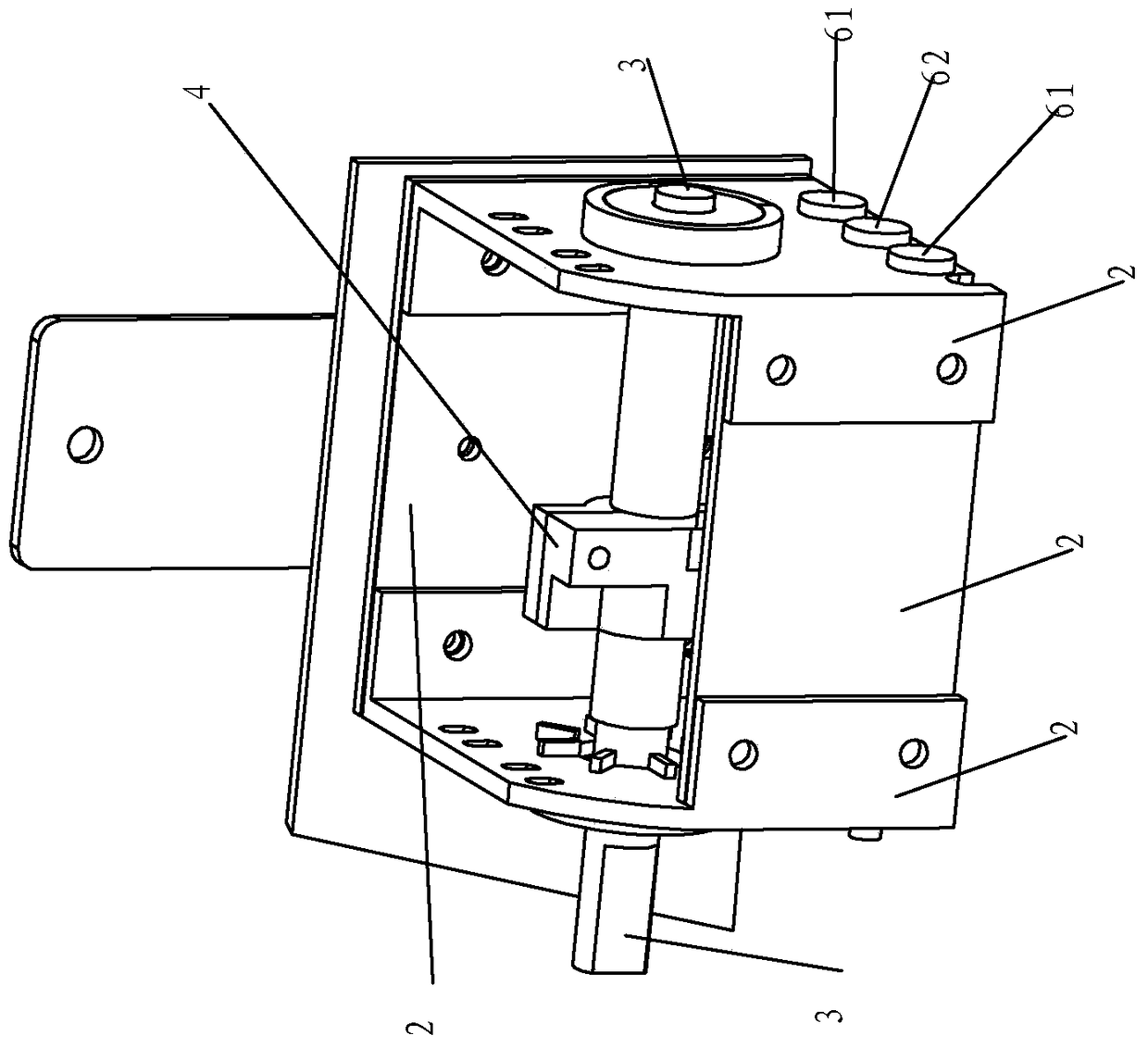

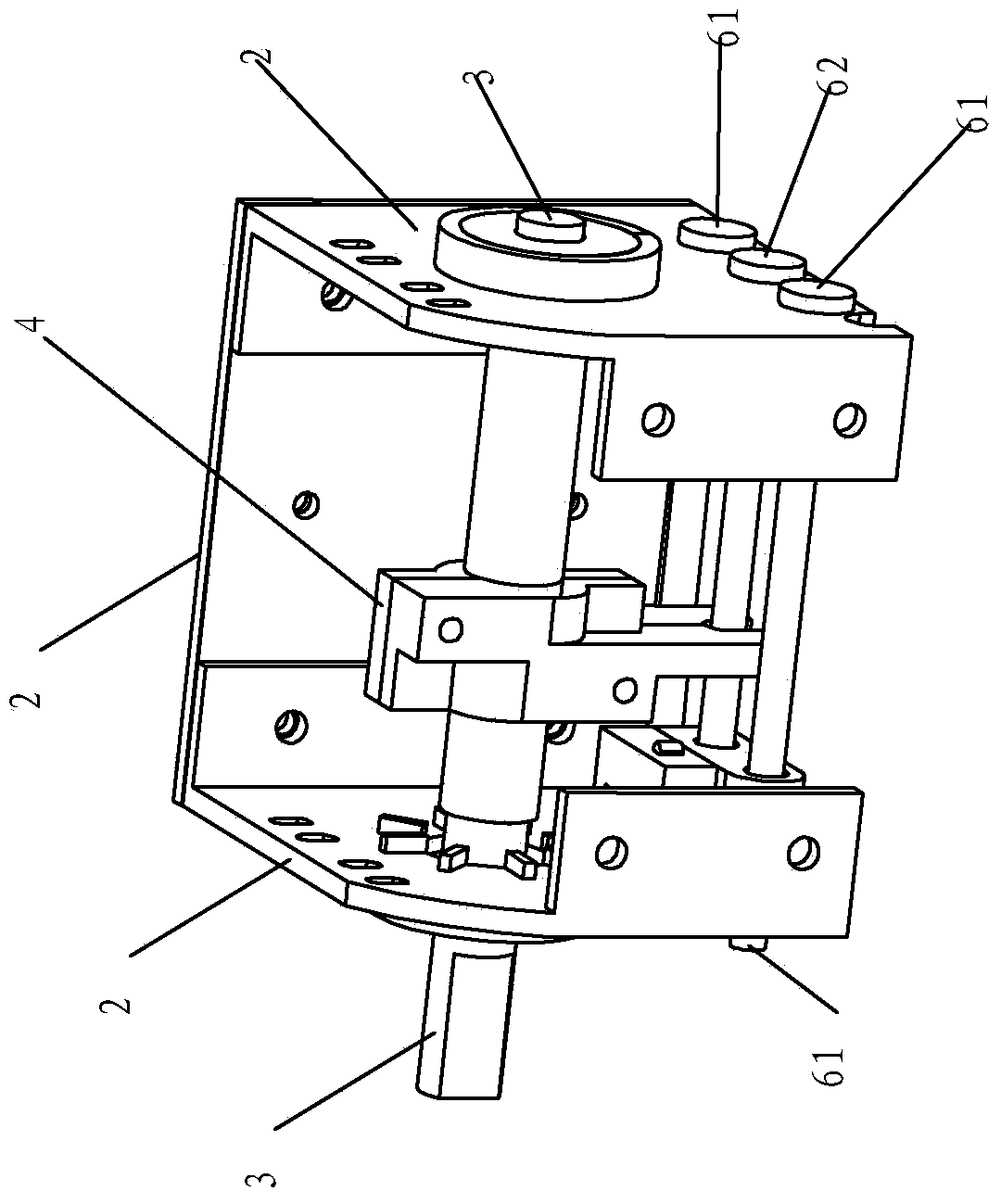

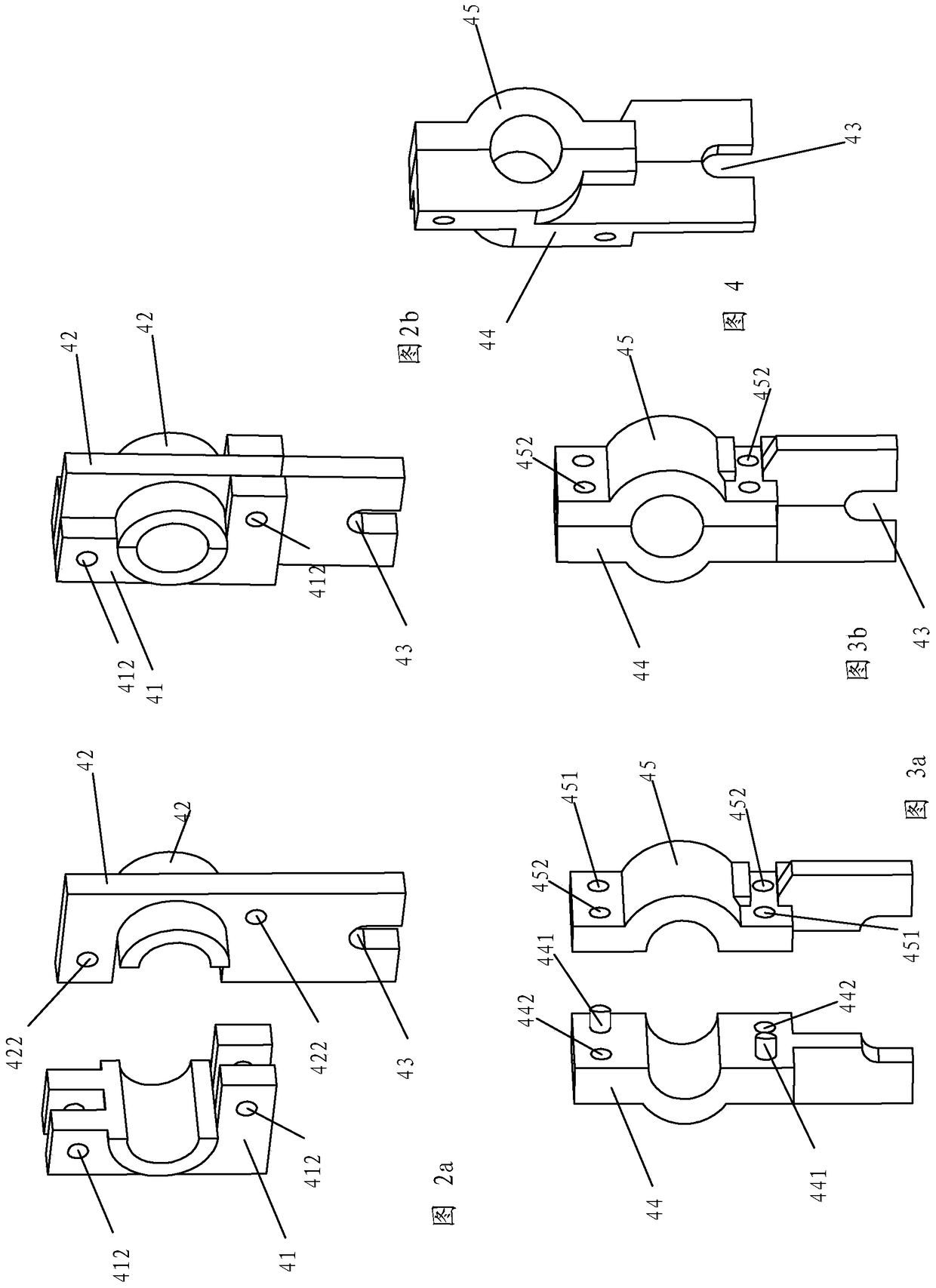

[0013] Example. see Figure 1a -b: The auxiliary end of the electric screen product includes the auxiliary end frame (2), the slave shaft screw (3), the pressure plate (4), the micro switch (51), the switch seat (52), the debugging bottom rod (61), the center Bottom rod (62) etc. The forward rotation and reverse rotation of the output shaft of the electric screen motor drive the forward rotation and reverse rotation of the roll tube that loads the screen cloth, and then determine the forward rotation and reverse rotation of the slave shaft screw (3) mounted in the auxiliary end frame (2) . The upper part of the pressure plate (4) is a nut matching the slave shaft screw (3), and the ∩-shaped opening (43) of the lower part of the pressure plate (4) is fastened to the midsole rod (62). When the middle bottom rod (62) prevents the ∩-shaped opening (43) from rotating with the upper nut, the forward rotation and reverse rotation of the slave shaft screw (3) will cause the nut of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com