A kind of agarwood essence used for agarwood cigarette mouth glue and its preparation method and application

A kind of technology of cigarette lap and agarwood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

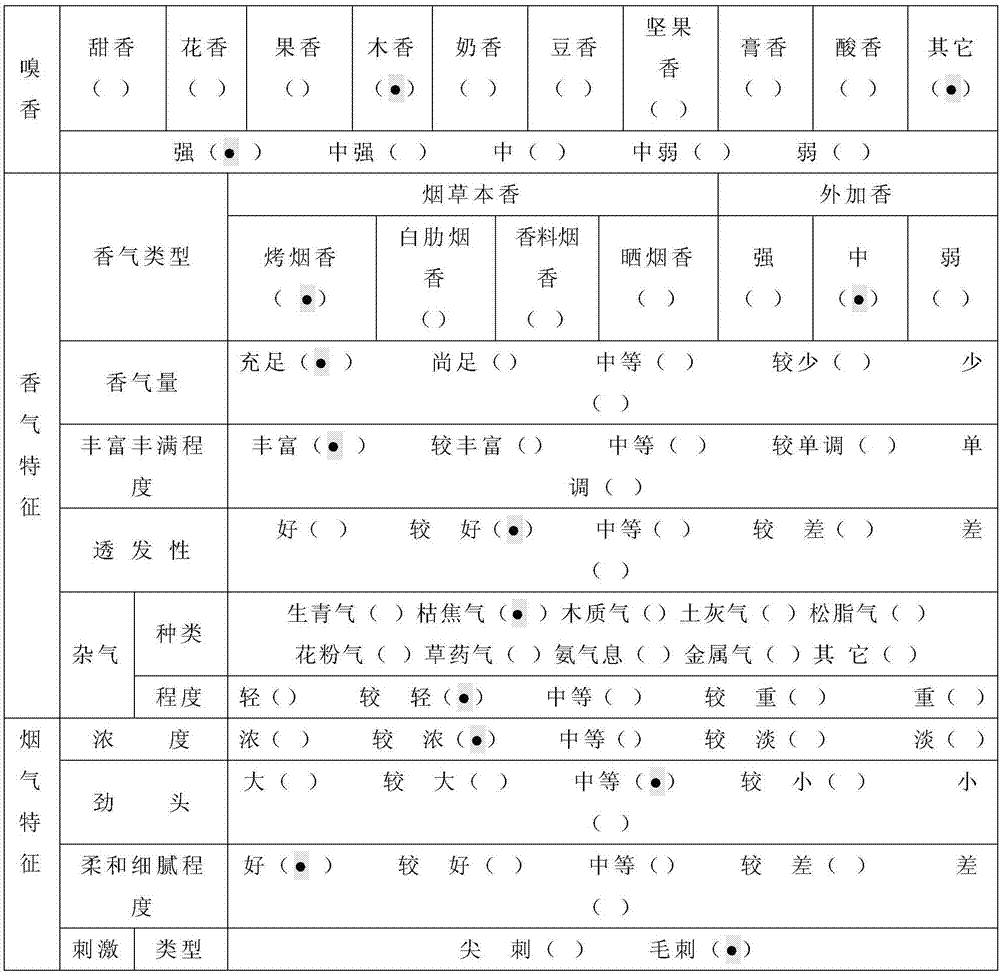

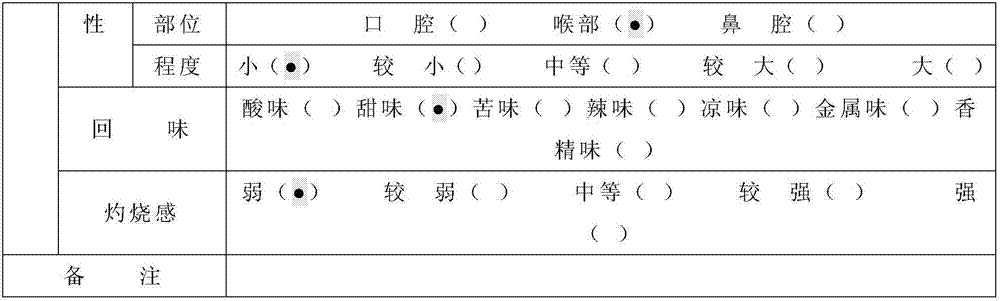

Image

Examples

Embodiment 1

[0023] Example 1. A method for preparing agarwood flavor for agarwood-type cigarette mouthpiece gum. The specific steps are as follows:

[0024] (1) Raw material production: a. After crushing the East Indian white sandalwood, pass it through a 100-150 mesh sieve, soak it in 70% ethanol of 20 times its mass for 7 hours, sonicate it for 60 minutes under the condition of ultrasonic power of 40W, and then filter. The filtrate was refluxed and extracted at 80°C for three times, and the extracts were combined to obtain the East Indian White Sandalwood Oil, which is for later use; b. Wash the Zimbabwe tobacco leaves, dry them, control the moisture content at 3-5%, and immediately crush them over 100- 150-mesh sieve, weigh the sieved Zimbabwe tobacco raw material according to the ratio of material-to-liquid mass ratio of 1:10, add 70% ethanol, heat reflux for 3 hours at 80°C, and then cool the resulting product to settle. , Take the supernatant and concentrate under reduced pressure to o...

Embodiment 2

[0027] Example 2. A method for preparing agarwood essence for agarwood-type cigarette mouthpiece, the specific steps are as follows:

[0028] (1) Production of raw materials: a. After crushing the East Indian white sandalwood wood through a 100-150 mesh sieve, soaking in 70% ethanol of 20 times its mass for 7 hours, sonicating for 60 minutes under the condition of ultrasonic power of 40W, and then filtering The filtrate was refluxed and extracted three times at 80°C, and the extracts were combined to obtain the East Indian white sandalwood oil for use; b. Wash the Zimbabwe tobacco leaves, dry them, control the moisture content at 3-5%, and immediately crush them over 100- 150-mesh sieve, weigh the sieved Zimbabwe tobacco raw materials according to the ratio of material-to-liquid mass ratio of 1:10, add 70% ethanol, heat reflux for 3 hours at 80°C, and then cool the resulting product to settle. , Take the supernatant and concentrate under reduced pressure to obtain the extract, wh...

Embodiment 3

[0031] Example 3, a method for preparing agarwood essence for agarwood-type cigarette mouthpiece, the specific steps are as follows:

[0032] (1) Production of raw materials: a. After crushing the East Indian white sandalwood wood through a 100-150 mesh sieve, soaking in 70% ethanol of 20 times its mass for 7 hours, sonicating for 60 minutes under the condition of ultrasonic power of 40W, and then filtering The filtrate was refluxed and extracted three times at 80°C, and the extracts were combined to obtain the East Indian white sandalwood oil for use; b. Wash the Zimbabwe tobacco leaves, dry them, control the moisture content at 3-5%, and immediately crush them over 100- 150-mesh sieve, weigh the sieved Zimbabwe tobacco raw materials according to the ratio of material-to-liquid mass ratio of 1:10, add 70% ethanol, heat reflux for 3 hours at 80°C, and then cool the resulting product to settle. , Take the supernatant and concentrate under reduced pressure to obtain the extract, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com