One-operating and one-standby type vacuum pump group for dust collector

A technology of vacuum pumps and dust collectors, which is applied in the direction of pumps, pump devices, mechanical equipment, etc., and can solve the problem that the continuous working time of the vacuum pump system cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

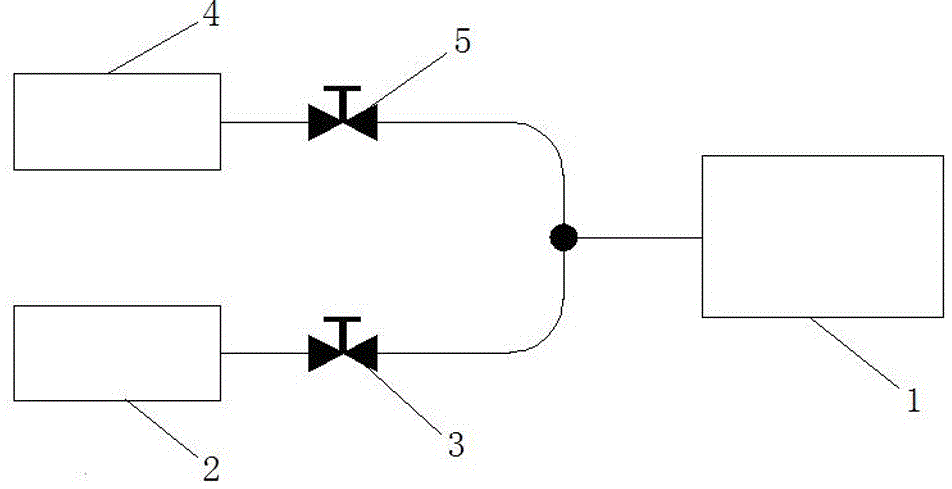

[0007] See figure 1 , A vacuum pump set with one open and one standby for dust collector, which includes vacuum chamber 1, vacuum pump set one 2, vacuum valve one 3, vacuum pump set two 4, vacuum valve two 5, said vacuum pump set one 2 is connected with vacuum valve one 3. , Vacuum pump group two 4 is connected with vacuum valve two 5, vacuum valve one 3 is connected in parallel with vacuum valve two 5 and then connected to vacuum chamber 1.

[0008] After the equipment is started, the vacuum pump group 1 and the vacuum valve 1 work to vacuum. During continuous operation, when any part of the vacuum pump group 1 fails due to long-term operation, the equipment automatically gives fault information, and the vacuum pump group is closed. A switching signal is given at the same time, and the equipment is automatically switched to the second vacuum pump group to ensure the normal operation of the equipment, and then the vacuum pump group one is fault-handled for backup. The invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com