Sequential control method and system in PLC

A sequence control system and sequence control technology, applied in the field of software programming, can solve the problems of occupying a large PLC storage space and low control efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

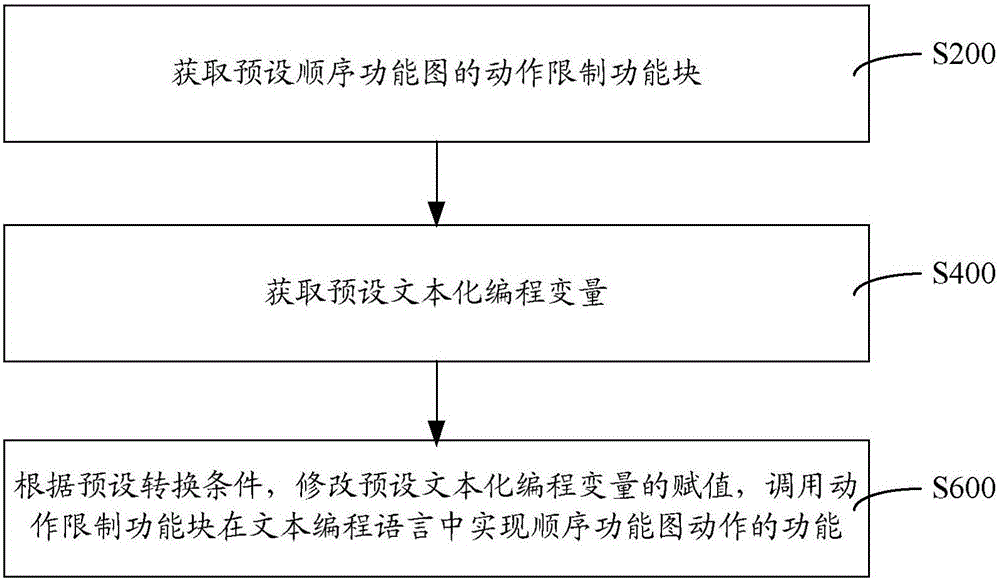

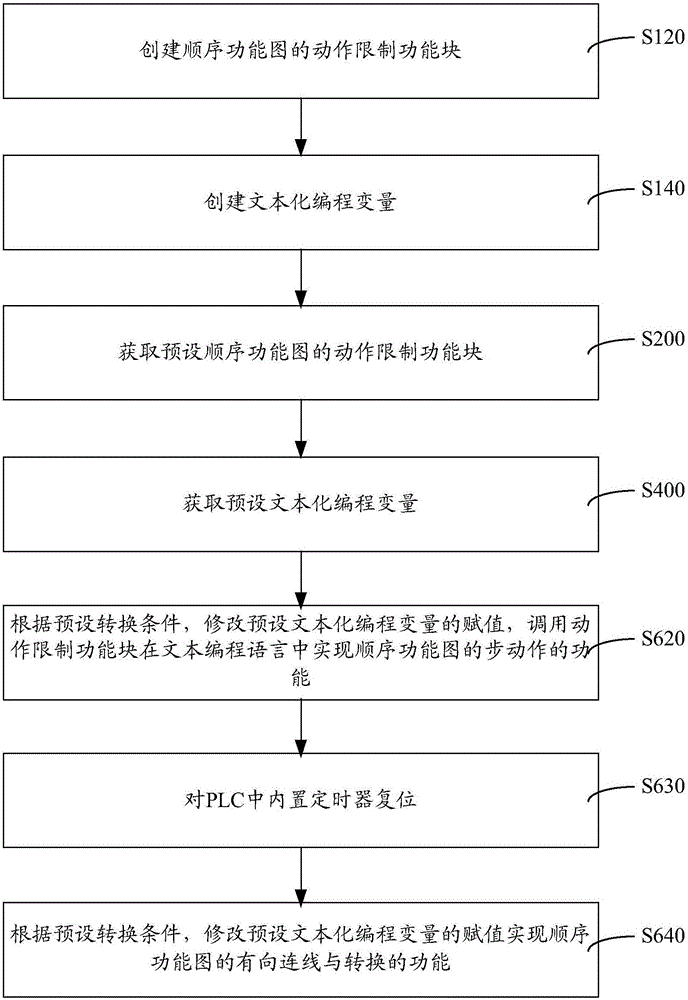

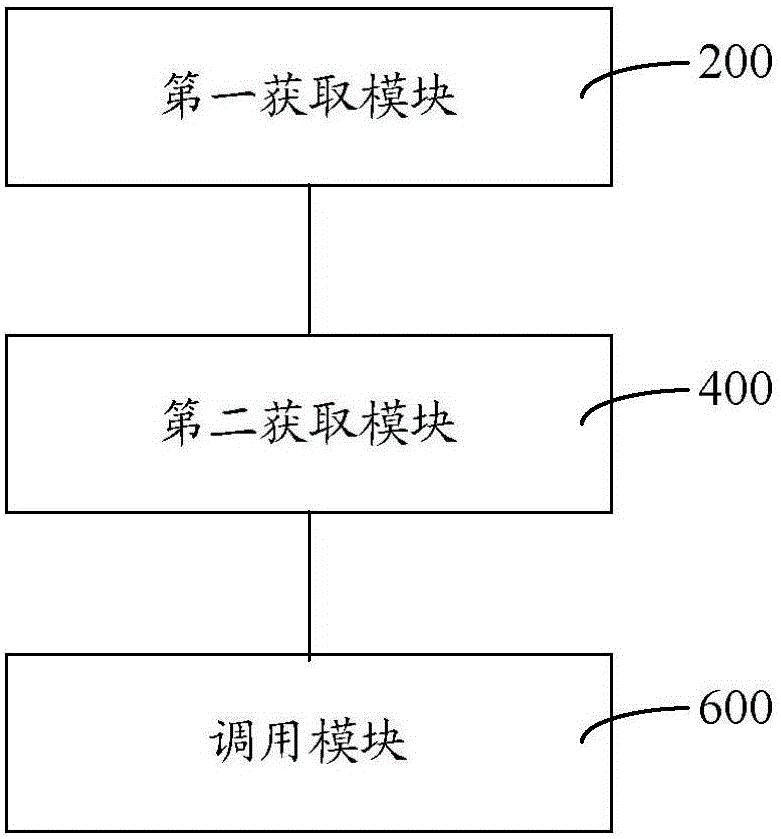

[0019] The programming language in PLC includes text programming language ST and sequential function chart SFC. Among them, the sequential function chart SFC programming language has strong program readability, and the action sequence of the equipment can be seen intuitively. When the equipment fails, it is easy to find the fault location. In the position, there is no need for complicated interlocking programs, and it is easier to design and maintain the system. However, in order to realize the above-mentioned diversified and comprehensive functions of the sequential function chart SFC programming language, its programming language needs to be compared with the text programming language ST It is much more complicated, and many contents of the Sequential Function Chart SFC programming language are seldom used in the PLC sequence control. In order to overcome the defect that the Sequential Function Chart SFC needs to occupy a large storage space of the PLC, the present invention c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com