Aircraft Constrained Optimization Method Based on Filter Technology and Subdivision Rectangle Algorithm

A constrained optimization and filter technology, applied in constraints-based CAD, instruments, calculations, etc., can solve problems such as the large impact of optimal design results, and achieve the effects of increasing design costs, enhancing robustness, and eliminating uncertainty.

- Summary

- Abstract

- Description

- Claims

- Application Information

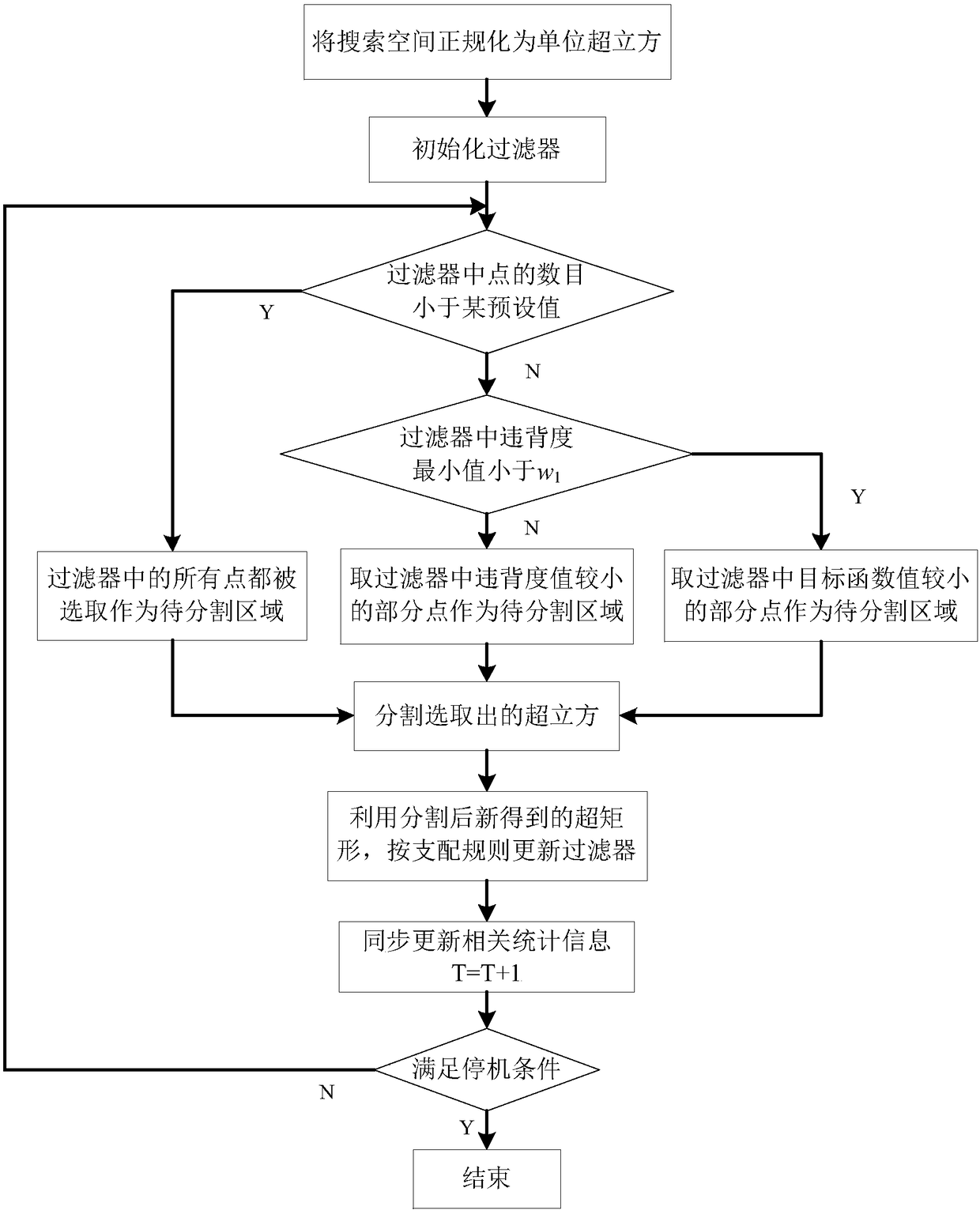

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Optimal Design of Light Aircraft Landing Gear Shock Absorbing Spring

[0032] Light aircraft have light take-off weight and relatively simple structure, and tension / compression springs are often used as shock absorbers for their landing gear. In order to reduce the structural mass of light and small aircraft, it is hoped that the mass of the spring should be minimized under the constraints of minimum deflection, shear stress and vibration frequency.

[0033] The total mass (objective function) of the damping spring design can be expressed as:

[0034]

[0035] where x 1 is the spring coil diameter d; x 2 is the average coil diameter D; x 3 is the effective number of turns N.

[0036] Constraints to be met by the design include:

[0037]

[0038] At the same time, the value range of each design variable is: 0.05≤x 1 ≤0.20, 0.25≤x 2 ≤1.30, 2.0≤x 3 ≤15.0, the schematic diagram is as follows Figure 4 shown.

[0039] The filter DIRECT (filter-DIRECT) and the...

Embodiment 2

[0054] Embodiment 2: Solid Rocket Motor Shell Design

[0055] The solid rocket motor shell is an important part of the solid rocket motor, and it is an important guarantee to ensure the static strength of the engine structure and the pressure bearing capacity of the combustion chamber. Solid rocket motors are mostly disposable consumables. Under the premise of satisfying the constraints, it is hoped that its total cost will be the smallest, including the cost of materials, forming and welding. The total cost (objective function) of solid rocket motor shell design can be expressed as

[0056]

[0057] where x 1 is the shell thickness T s ; x 2 is the thickness of the cap T h ; x 3 is the inner diameter R; x 4 is the length L of the cylindrical part, the schematic diagram is as follows Figure 5 shown.

[0058] The material, forming and welding constraints that the design needs to satisfy are described as follows

[0059]

[0060] Using the optimization design met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com