Device for removing weft thread

A technology of weft yarn and weft detector, used in textiles and papermaking, looms, textiles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

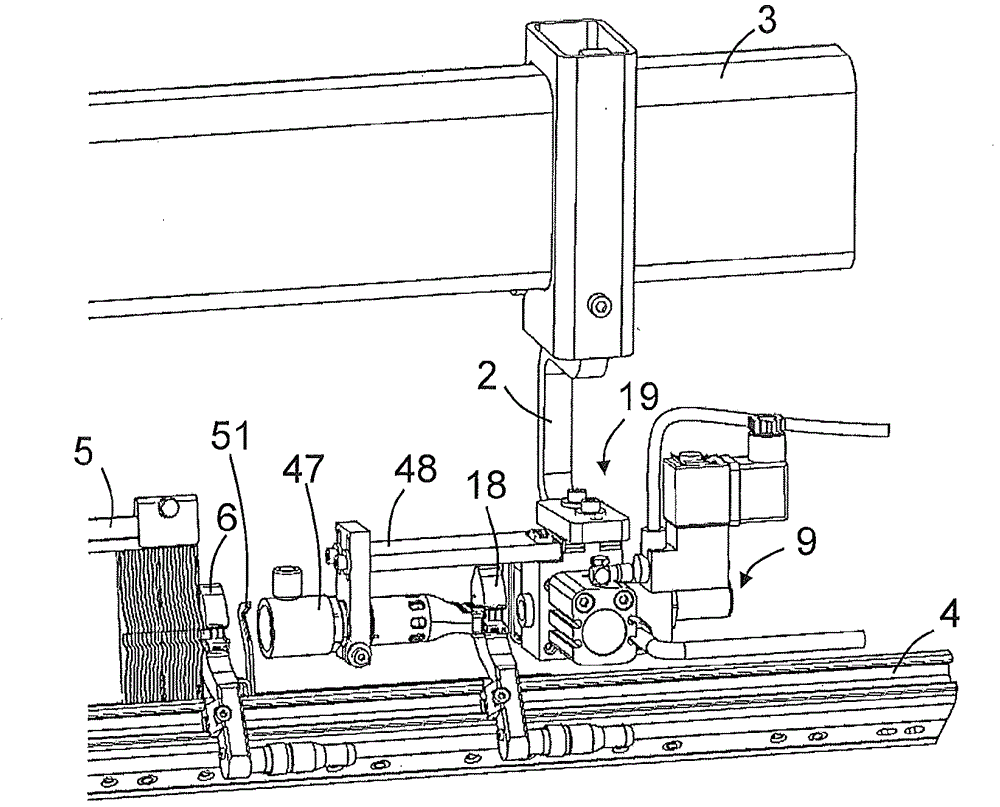

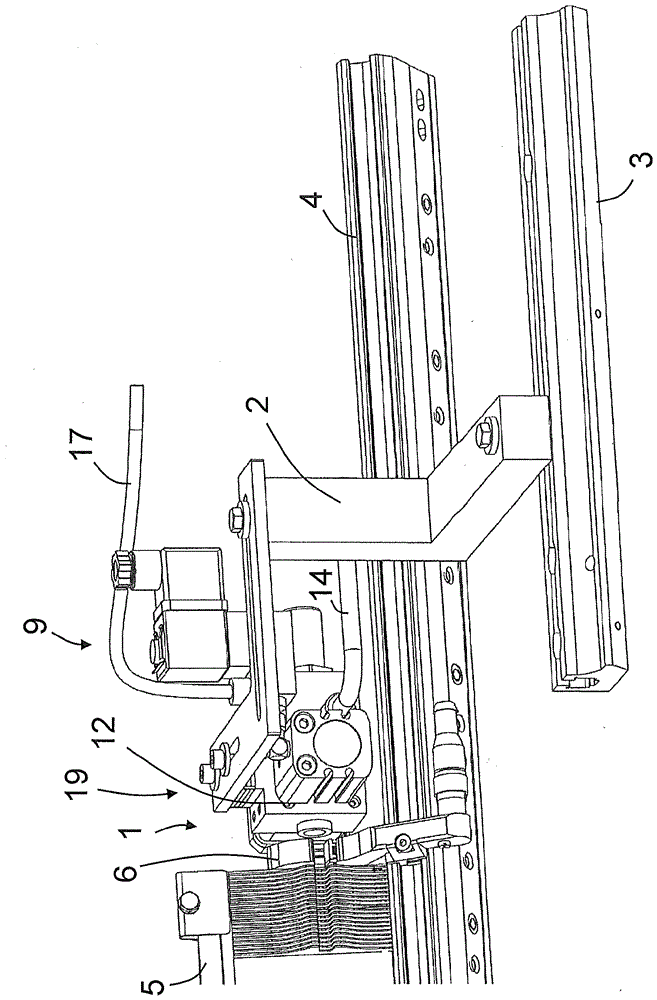

[0022] exist figure 1 , schematically shows a part of the loom in the area on the opposite side of the shed (not shown). Here is shown a device 1 according to the invention fastened via a fastening system 2 to a beam 3 of a weaving machine. Also shown is a part of the sley 4 on which the reed 5 and the weft finder 6 are mounted.

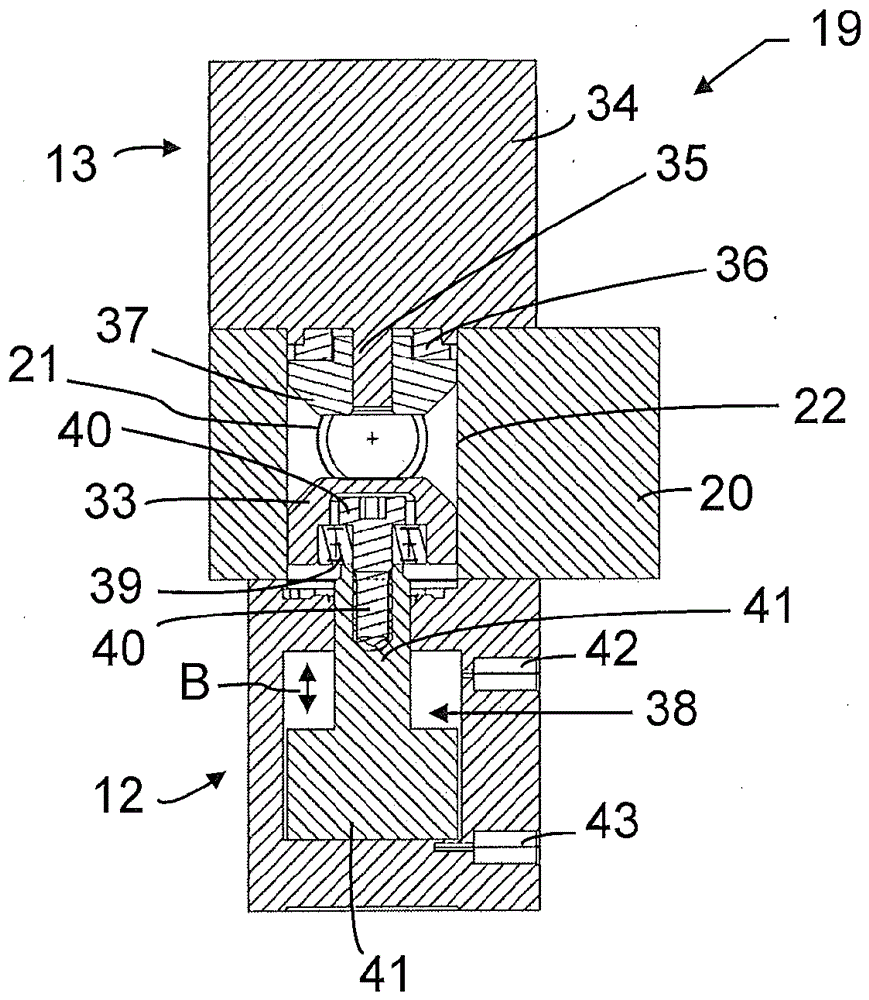

[0023] When the weft feeler 6 detects an incorrectly inserted weft thread, the weaving process is interrupted. According to one embodiment, the next inserted weft thread 10 connected to the incorrectly inserted weft thread 11 is then passed through the shed to the device 1 according to the invention in a known manner, for example according to a method known from NL 86 02191 A . It is also known here, after detection of an incorrectly inserted weft thread, to release a limited amount of weft thread in the region of the thread supply and not to cut the incorrectly inserted weft thread 11 from the thread supply. Here, both weft threads 10, 11 are br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com