A double-layer solid wood composite floor and its preparation method

A solid wood composite floor, double-layer technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of surface cracking, poor stress capacity, and many glue layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0034] The following examples are only examples for clearly illustrating the present invention, rather than limiting the implementation of the present invention. For those of ordinary skill in the art, on the basis of the following descriptions, other different forms of changes or changes can also be made, and these obvious changes or changes that belong to the spirit of the present invention are still within the protection scope of the present invention middle.

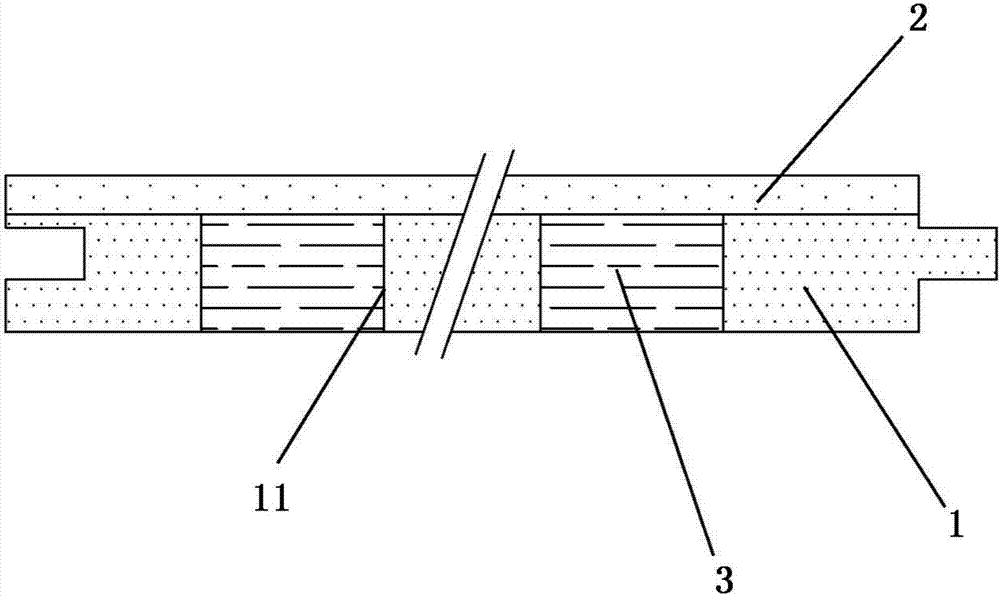

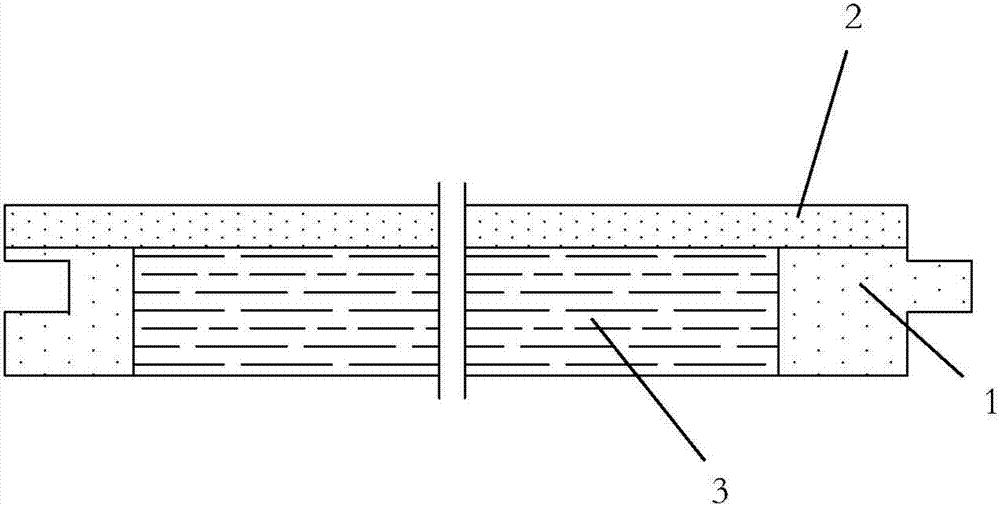

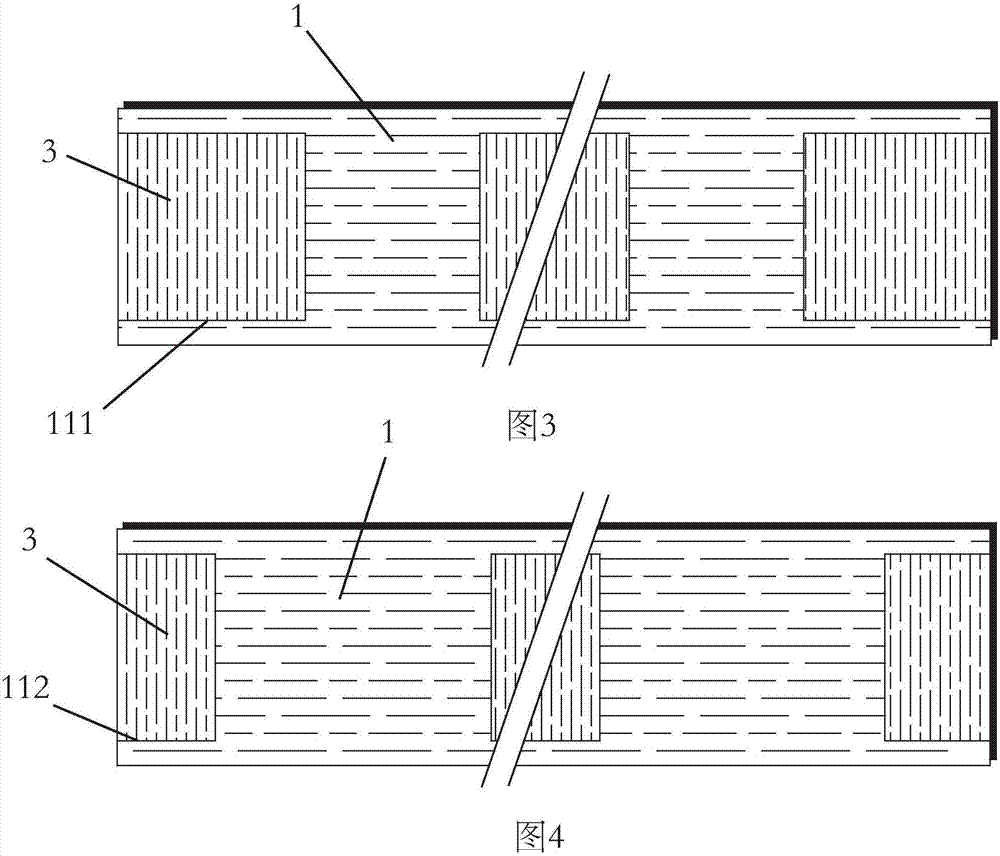

[0035] A double-layer solid wood composite floor and a preparation method thereof, comprising a plurality of floor boards spliced together, the floor boards include a back board 1 and a front board 2, and a plurality of Equally large hollow through holes 11, a glue layer is arranged between the front board 2 and the back board 1 and hot-pressed to form a double-layer wood board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com