Integrated rapid level measuring device with ruler and meter

A level measurement and fast technology, applied in the direction of measuring devices, height/level measurement, instruments, etc., can solve the problems of consuming energy and time of surveyors, difficulty in balancing, stable placement, impractical leveling measurement, etc., and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

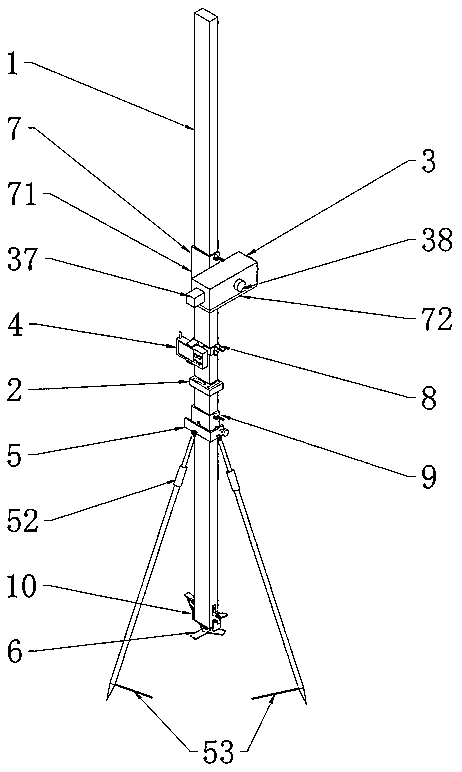

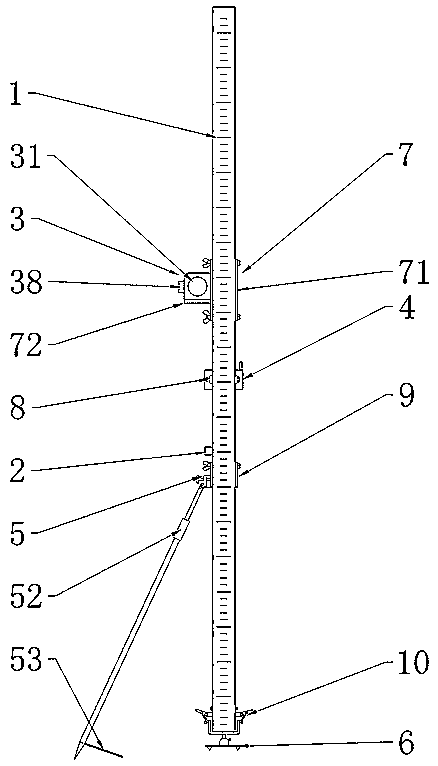

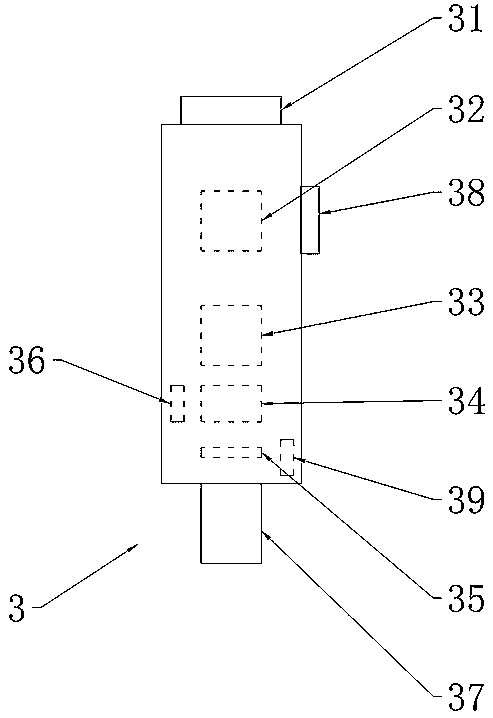

[0015] Such as figure 1 , 2 , shown in 3, 4, 5, and 6: a leveling rod 1 with a height of 2 to 4 meters made of metal, plastic or wood, etc., with a scale on the surface, and a leveling device 2 is also fixedly connected to the middle part of the leveling rod 1 , the level 2 adopts two tube levels arranged orthogonally. The height measuring device 3 is fixed on the leveling rod 1 by the first connecting piece 7, the first connecting piece 7 is made of a scale connecting piece 71 and a bracket 72, the scale connecting piece 71 adopts a U-shaped fixing ring and a fastening bolt, etc. The frame 72 adopts a draw-in groove or a supporting plate, and the height measuring device 3 is placed on the bracket 72 . The height measuring device 3 is composed of an objective lens 31, a focusing lens 32, an automatic horizontal line of sight compensator 33, a beam splitter 34, a crosshair reticle 35, an electronic reading device 36, and an electronic eyepiece 37 arranged in sequence along th...

Embodiment 2

[0021] Such as Figure 8 , 9, shown in 10: the basic structure is the same as embodiment 1, and the difference is: the scale connector 71 of the first connector 7 adopts a slideway 73, a slide block 74, and the slideway 73 is fixedly connected with the leveling rod 1, and the bracket 72 is connected with the leveling rod 1. The slide block 74 is fixedly connected, and the altimeter 3 can move up and down along the leveling staff 1. The scale connecting part 81 of the second connecting part 8 is connected with the hand book fixture 82 in rotation, and the observation hand book 4 can be tilted and rotated up and down, which is convenient for the surveyor to operate. The third connector 9 adopts a G-shaped clamp, and the transverse base frame 51 of the auxiliary support 5 is composed of an inner annular transverse base frame 51-1 and an outer annular transverse base frame 51-2, and the inner annular transverse base frame 51-1 is connected to the outer annular transverse base fra...

Embodiment 3

[0024] Such as Figure 11 , 12 Shown: the basic structure is the same as in embodiment 1, the difference is that the leveling scale 1 adopts a two-section combined cylindrical scale body or a tower chi, that is, the upper section chi 11 and the lower section chi 12 are combined through a fixed connector 13, Easy to carry for surveyors. The scale connector 71 adopts a linear fixing strip and fastening bolts. The observation handbook 4 is provided with a status indicator light 45 or a voice prompter (speaker) 46 and a remote controller 47, which are convenient for information communication and synchronous measurement between the two level gauges A and B. The level 2 is provided with a bubble position detector 21 and an alarm 22, and the height measuring device 3 is also provided with a pentaprism 310 and a mirror 311, and a focusing lens 32, an automatic horizontal line of sight compensator 33, a beam splitter 34, a crosshair Reticle 35, electronic reading device 36, and elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com