Hydraulic leveling measurement system and measurement method thereof

A technology of leveling and measuring methods, applied in height/level measuring, measuring devices, surveying and navigation, etc., can solve the problems of measurement principle and range limitation, large impact of static level temperature, high labor intensity of measurement work, etc., to achieve Improve measurement frequency, low cost, save time and labor for installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

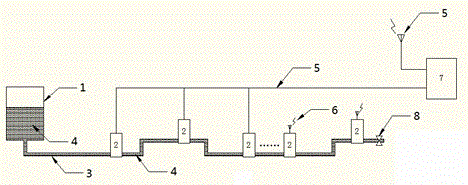

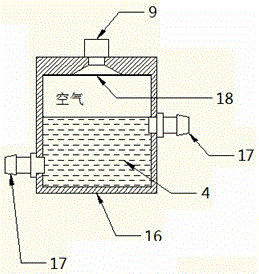

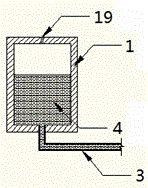

[0056] The invention specifically discloses a hydraulic level measurement system, which combines figure 1 As shown, it includes a liquid storage tank 1 provided with measuring liquid, and a measurement unit 2 connected to the outlet of the liquid storage tank 1 through a communication pipe 3 . The measuring unit is placed on the measuring point and the reference point. The measuring unit is a hydraulic sealing tank, and an absolute pressure sensor is arranged above the hydraulic sealing tank. The absolute pressure sensor is a liquid absolute pressure sensor or a gas absolute pressure sensor.

[0057] combine Figure 3-Figure 5 As shown, in order to eliminate the impact of external wind pressure and loud sound on the system caused by atmospheric pressure jitter, the liquid storage tank 1 cannot be directly exposed to the atmosphere, and a small hole 19 is arranged on the top of the liquid storage tank 1 or through It is connected with an elongated connecting pipe 20 to commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com