A new packaging component for strip steel coils

A technology of steel coils and components, which is applied in the field of packaging components of new strip steel coils, can solve the problems of limited steel strip strength, low material utilization rate, and low work efficiency, and achieve good packaging strength, good replacement, and easy loading and unloading Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

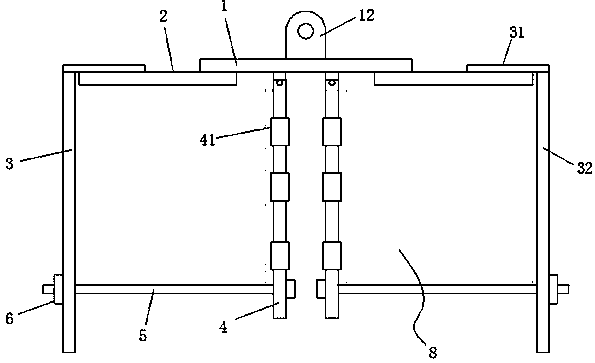

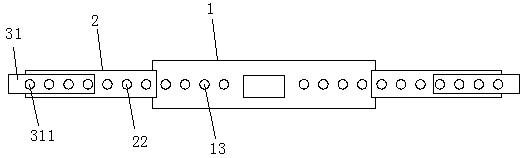

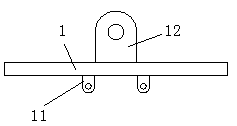

[0020] The present invention will be further explained below in conjunction with the drawings.

[0021] Such as Figure 1 to Figure 3 As shown, a new type of packaging component for strip steel coils of the present invention includes a mounting plate 1, a connecting plate 2, a side rod 3, a middle support rod 4, a connecting piece 5 and a fastening nut 6. Both middle support rods 4 are Hinged on the middle of the mounting plate 1, the two connecting plates 2 are fixedly connected to the left and right sides of the mounting plate 1, the side bars 3 on both sides are fixedly connected to the two connecting plates 2, and the two connecting pieces 5 are respectively connected to the left and right sides. On the middle support rod 4 and the side rod 3, the fastening nut 6 is threadedly connected to the connecting piece 5.

[0022] The mounting plate 1, the connecting plate 2, the side rods 3 and the middle support rod 4 in the present invention are detachable structures. The middle supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com