Cross flow type cooling column plastics filling agent

A cooling tower and cross-flow technology, which is applied in the field of plastic packing of cross-flow cooling towers, can solve the problems of low packing strength and low heat dissipation efficiency, and achieve good packing strength, high heat dissipation efficiency, thermal performance and resistance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

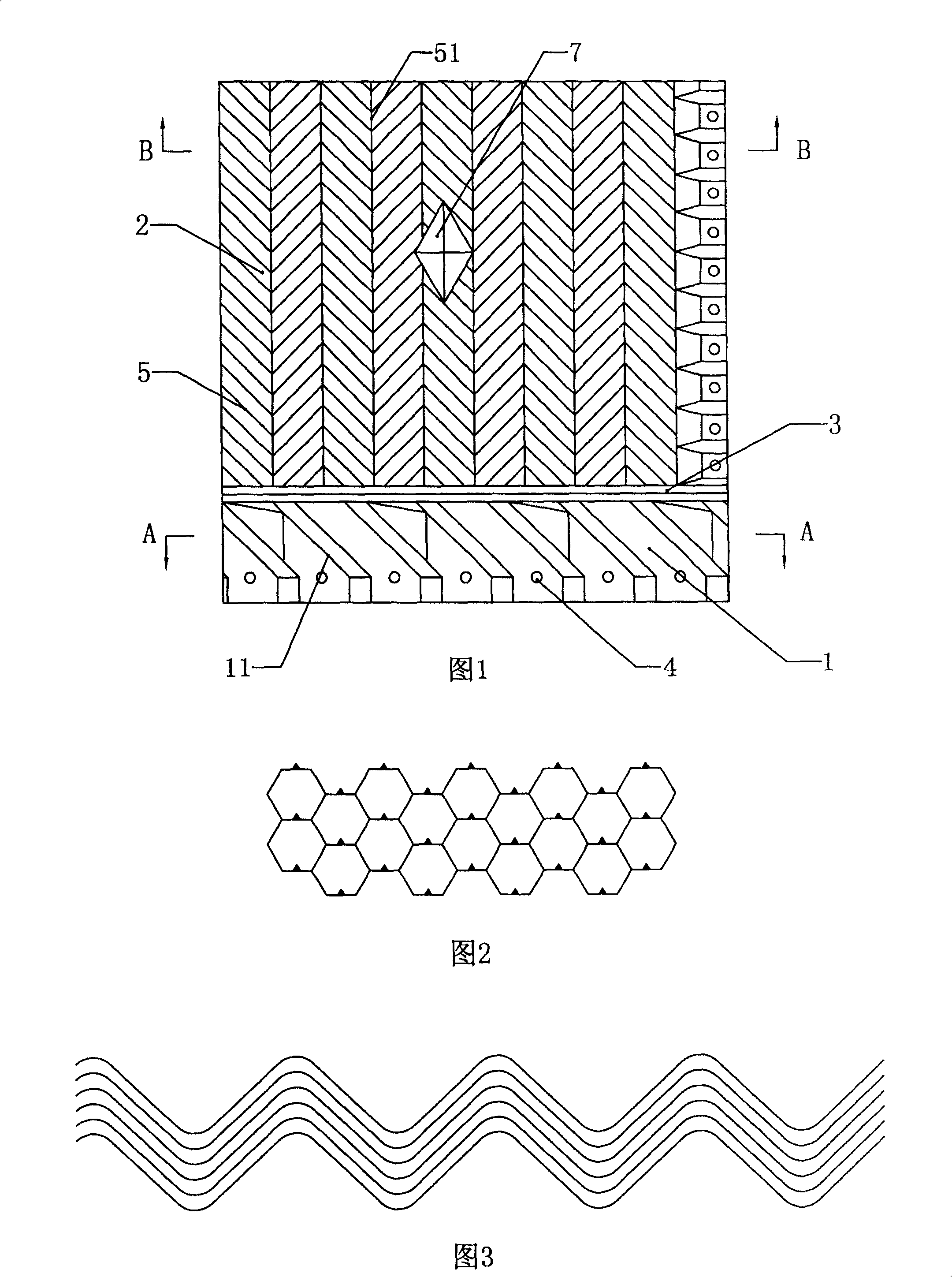

[0017] Example 1: Use rigid polyvinyl chloride PVC steel mold to vacuum-absorb the water spraying sheet. The water spraying sheet is divided into a cooling zone 2 and an auxiliary zone 1. The auxiliary zone 1 is divided into three sections: a wind guide section, a water collection section and a water diversion section. Part, there is a gap between the auxiliary area 1 and the cooling area 2 with ribs 5; the auxiliary area 1 is injection-molded into trapezoidal corrugations, and a concave-convex mounting head 4 is provided on the trapezoidal corrugations; ° angle; the cooling zone 2 is provided with secondary corrugations, the main corrugation is a sine corrugation, the secondary corrugation is a "V" wave 5, the wavelength of the sine corrugation is 100mm, the amplitude is 25mm, and the width of the "V" wave 5 is 10mm (such as figure 1 Shown); On the "V" wave 5 surface, an oblique wave is provided, and the oblique wave and the "V" wave 5 form an angle of 45°; the axis 51 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com