Internal flanging puncher pin

A technology of inner flanging and punching, which is applied in the field of pipe end forming processing molds, and can solve the problems of complex procedures, inability to carry out at the same time, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

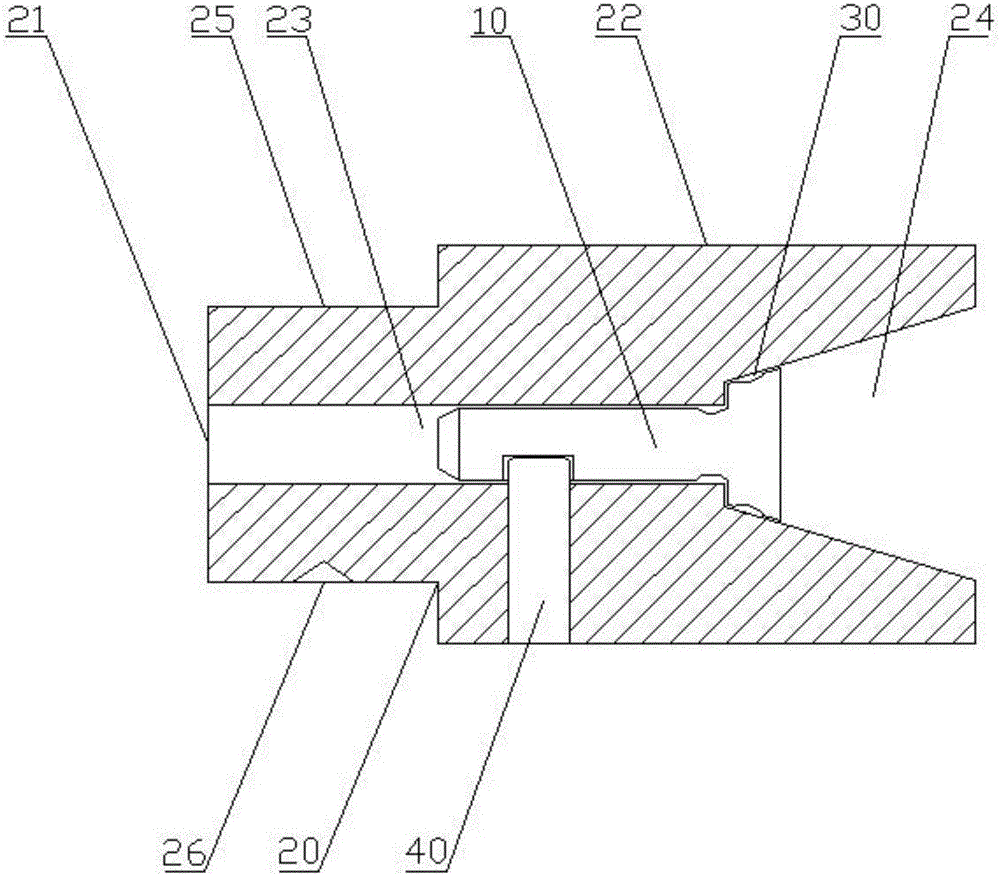

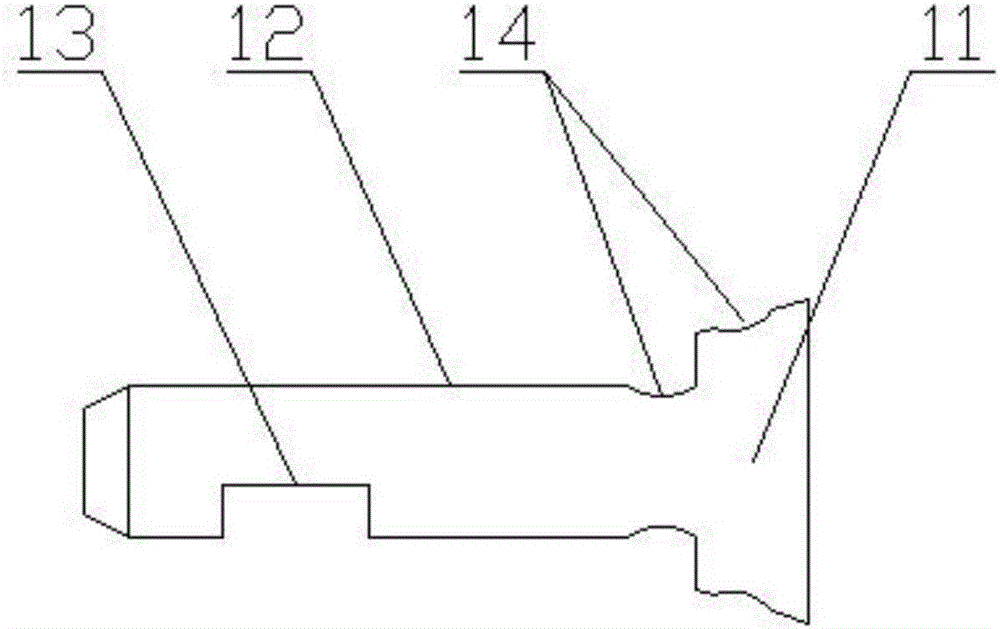

[0020] see figure 1 with figure 2 , an inner flanging punch described in a preferred embodiment of the present invention includes a deburring core 10 and an inner flanging jacket 20 detachably connected to the deburring core 10 . One end of the deburring mold core 10 is a deburring end 11, and the other end is a connecting end 12. The deburring end 11 is tapered in diameter gradually narrowing toward the connecting end 12. The deburring mold core 10 is installed in the inner hole 21 of the inner flanging overcoat 20, one end of the inner flanging overcoat 20 is the inner flanging end 22, the other end is the mounting end 25, and the outer diameter of the mounting end 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com