Lifting platform car capable of achieving height adjustment based on ball screw

A technology of lifting platform car and ball screw, which is applied in the direction of lifting device, etc., can solve the problems that the height of the ladder cannot be folded, the height of the platform device cannot be adjusted, and is fixed. Precise effect of lifting position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

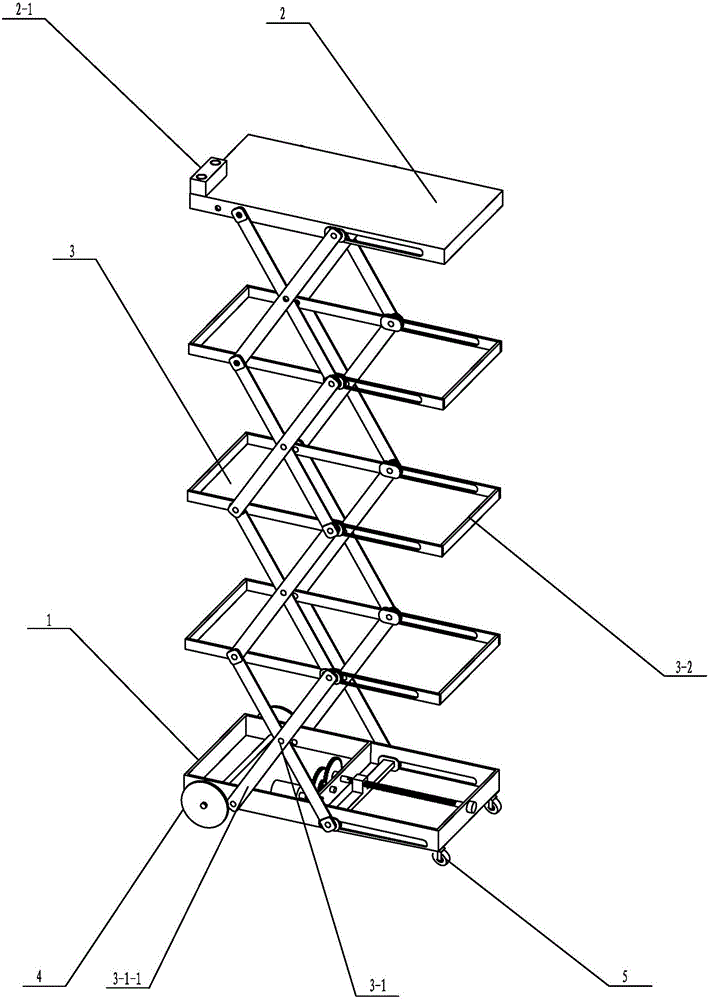

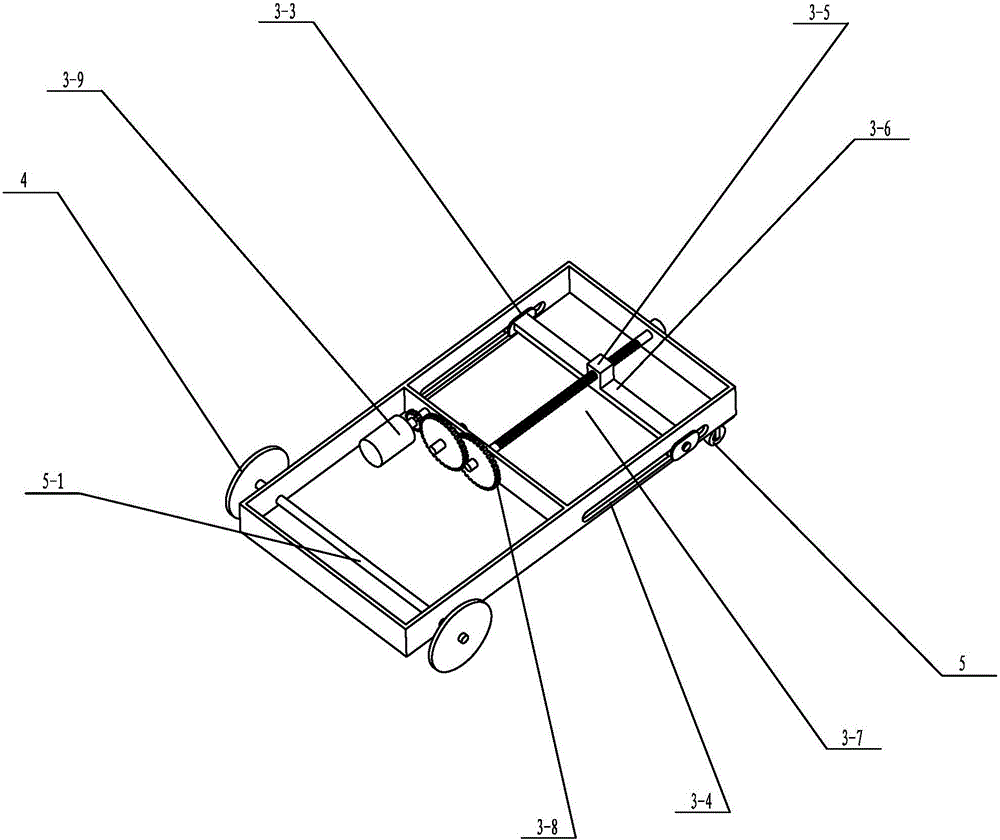

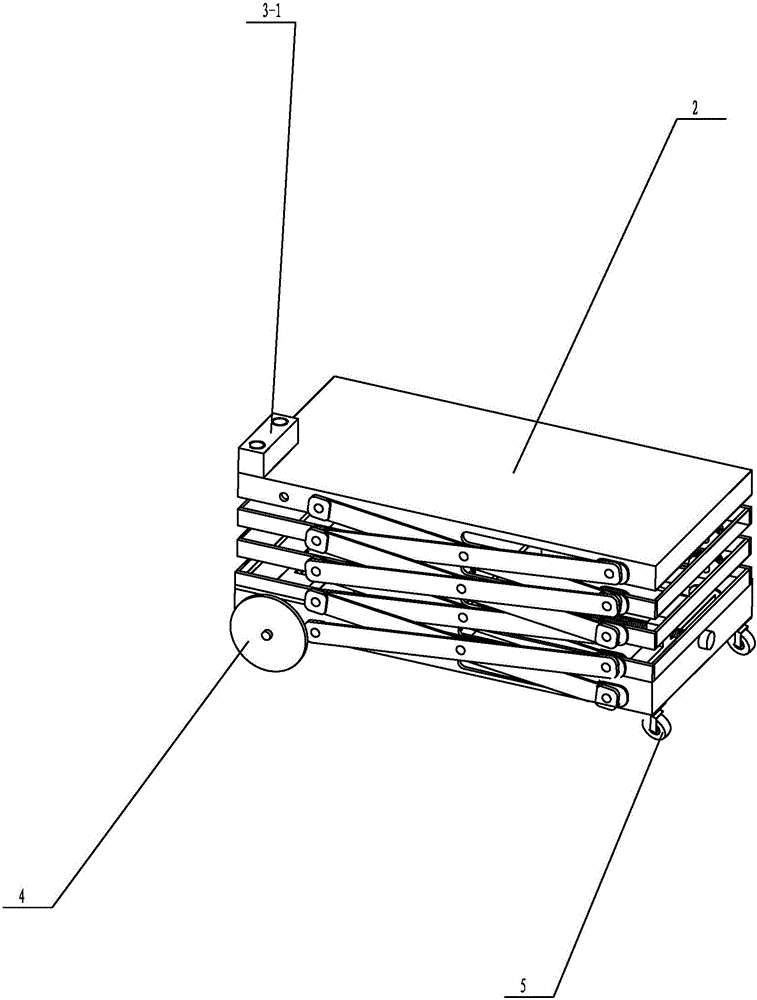

[0016] Such as figure 1 and figure 2 As shown, a specific embodiment of the present invention is proposed. The height-adjustable lifting platform vehicle based on a ball screw includes a chassis 1 and a lifting platform 2 arranged on the chassis 1. One end of the chassis 1 is symmetrically provided with rolling wheels 4 on both sides. , The bottom of both sides of the other end is symmetrically provided with universal wheels 5, and the two rolling wheels 4 are connected by a transmission shaft 4-1, and the chassis 1 and the lifting platform 2 are connected by a lifting assembly 3, and the lifting assembly 3 It includes several sets of lifting movable rod groups 3-1 symmetrically arranged on both sides between the lifting platform 2 and the chassis 1, and arranged up and down. The adjacent lifting movable rod groups 3-1 are hinged to each other, and the hinges are provided with lifting supports. Frame 3-2, the group of lifting movable rods 3-1 includes two movable rods 3-1-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com