A pressure regulating component for a natural gas pipeline

A technology for natural gas pipelines and pressure regulation, which is applied to engine components, safety valves, balance valves, etc., can solve the problems of many movements, difficulty in pressure regulation accuracy meeting design requirements, long secondary balance time, etc., and achieves a short pressure balance process. , Simple structure, good pressure regulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

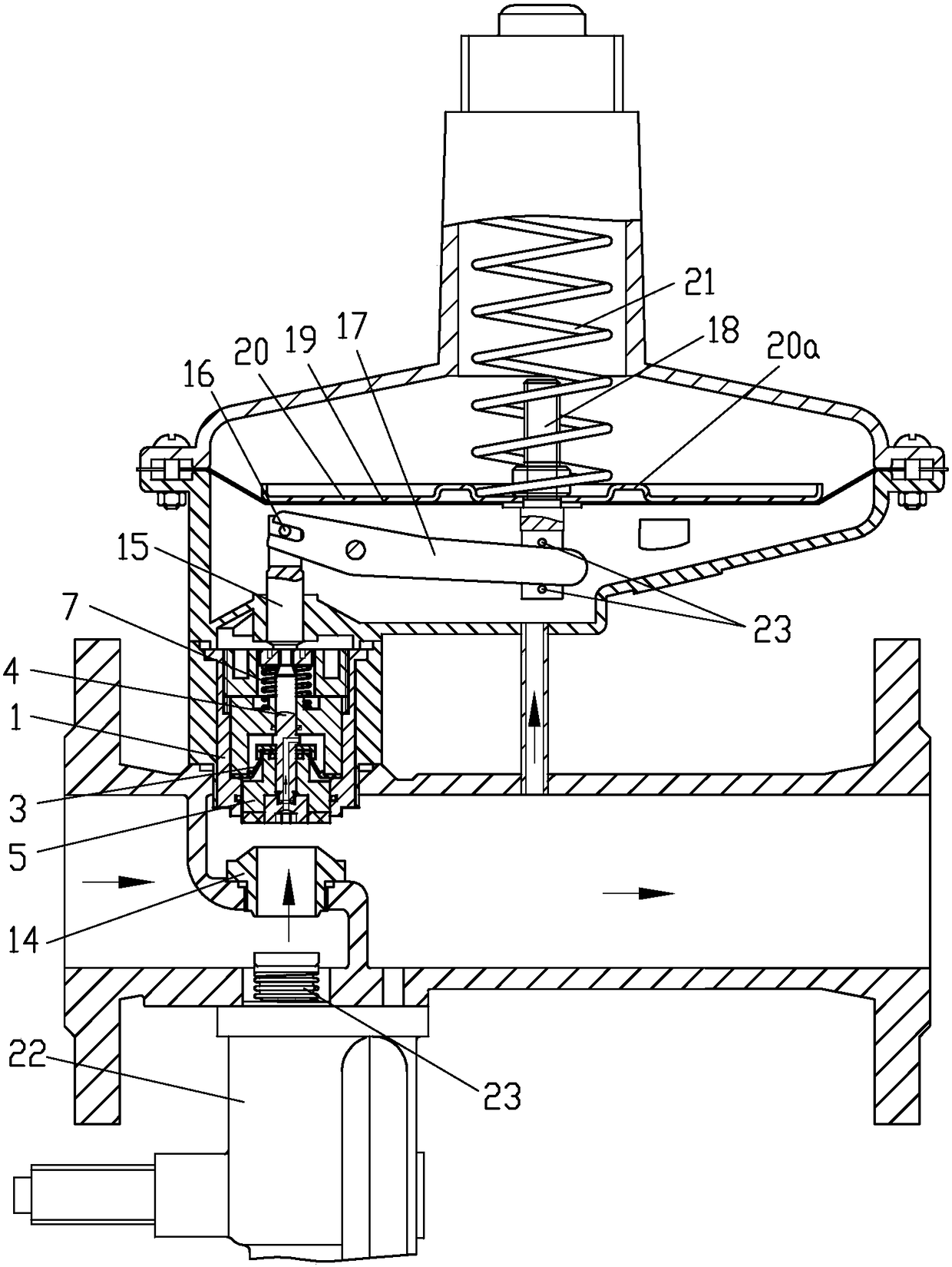

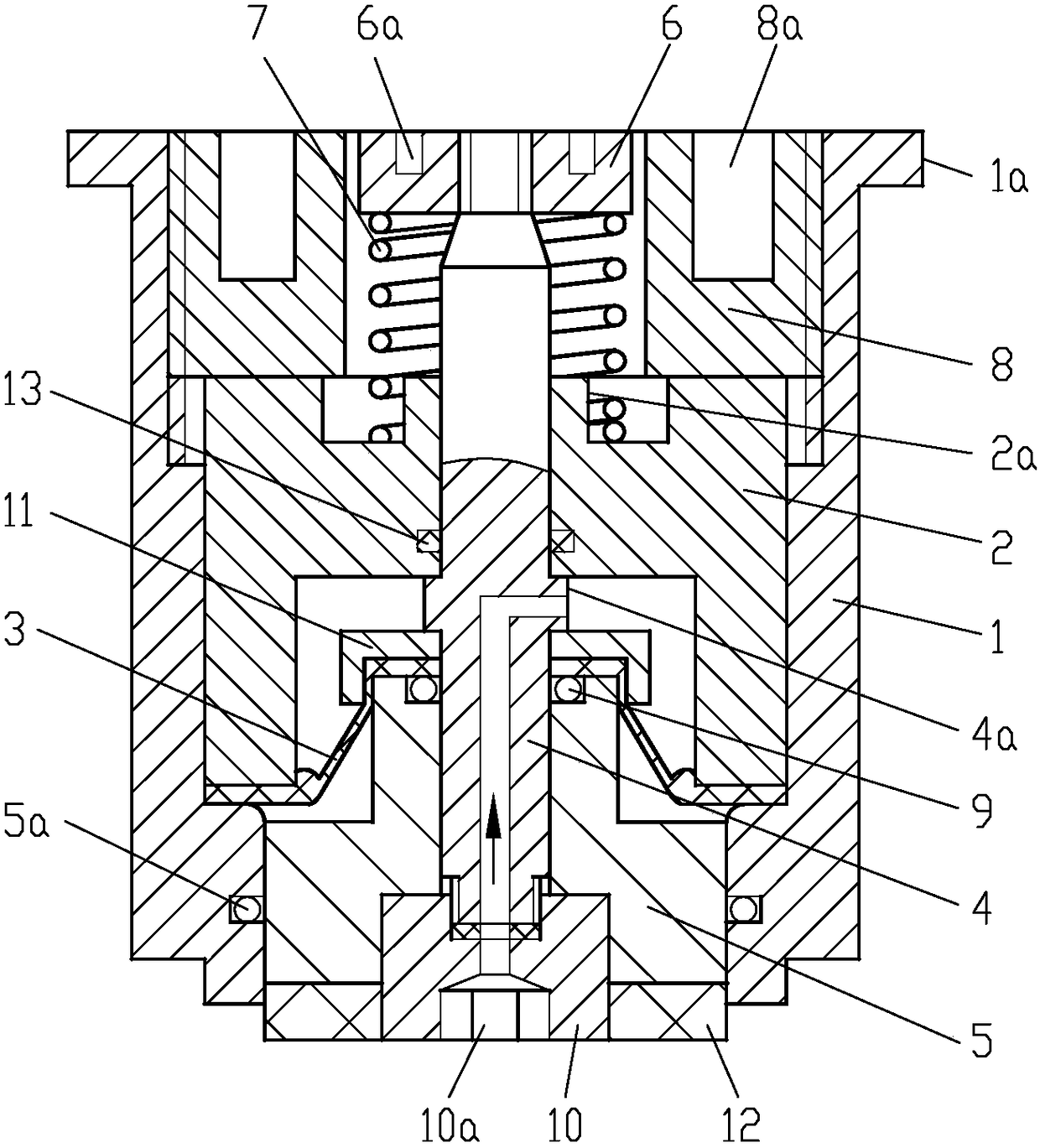

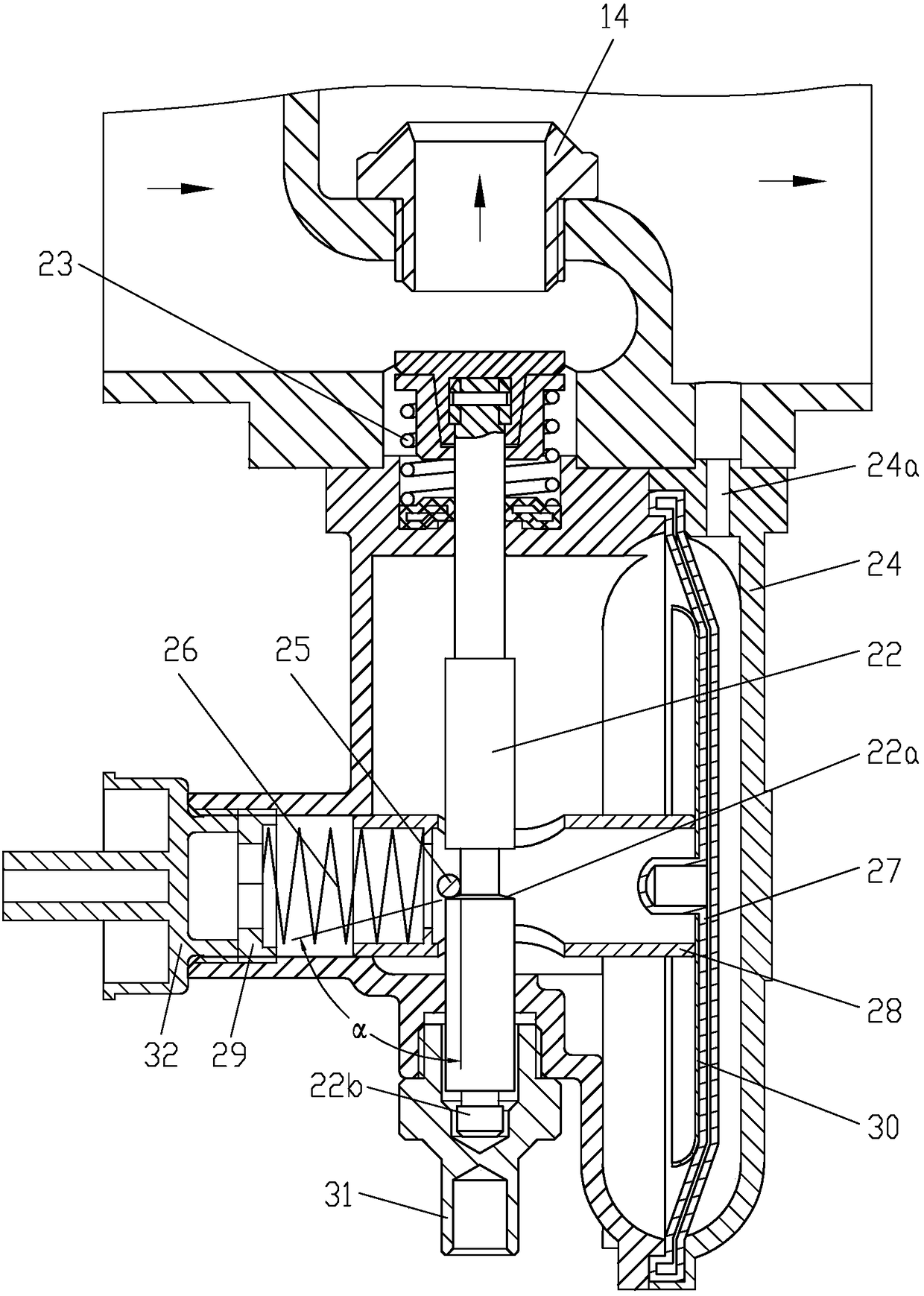

[0020] see figure 1 , figure 2 , image 3 , a pressure regulating assembly for a natural gas pipeline, comprising a valve port 14 communicating with a pressure regulation front section and a pressure regulation rear section, the inlet end and the outlet end of the valve port 14 are respectively provided with a shut-off valve and a pressure regulator, and the shut-off valve of the shut-off valve The valve core 22 is connected with a locking mechanism that is unlocked by the gas pressure after pressure regulation, and the cut-off valve core 22 is formed by a cut-off driving spring 23 to form a blocking pressure; the outlet end of the valve port 14 is provided with a pressure regulator, and the pressure regulator There is a main valve core 15 driven by a primary self-balancing structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com