Testing apparatus for attenuation law of stress wave of quasi-brittle materials under explosion and quantitative characterization method

A technology of stress wave attenuation and brittle materials, which is applied in the direction of measuring devices, analyzing materials, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc. It can solve the problems that the damage zone test cannot be implemented well, and achieve the reduction of dispersion and application Flexible, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

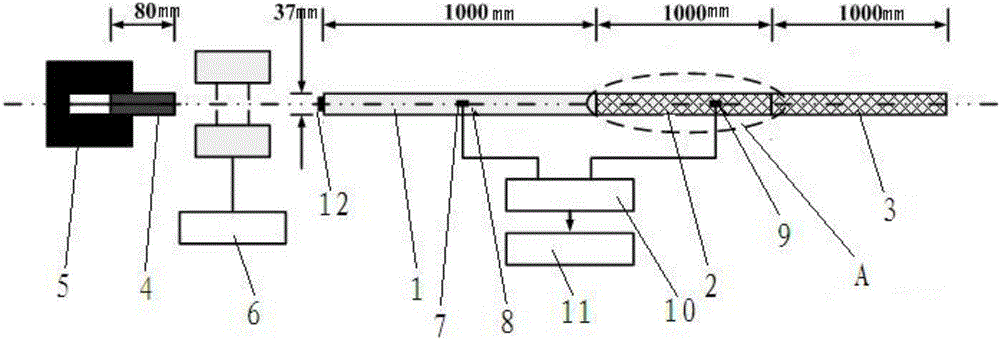

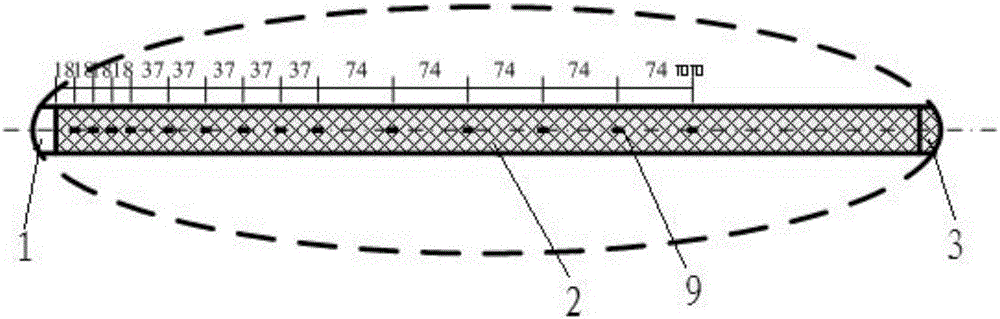

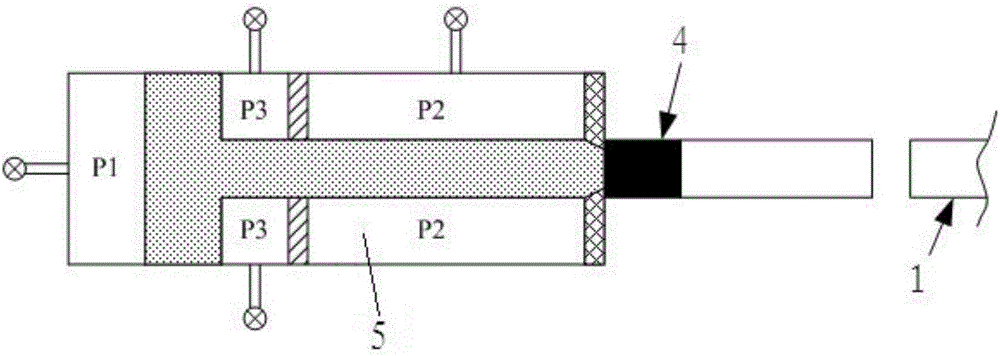

[0025] Such as Figure 1 to Figure 4 As shown, the test device for the stress wave attenuation law of quasi-brittle materials under explosion is a device for measuring stress wave attenuation based on Hopkinson's principle. It uses the Hopkinson rod technology for testing, including incident rod 1, bullet 4, Air source 5, speedometer 6, shaping sheet 12, energy-absorbing rod 3, specimen rod 2, strain gauge 7, data acquisition instrument 10, oscilloscope 11, etc., wherein, energy-absorbing rod 3 and specimen rod 2 are all concrete materials . What the incident rod 1 adopted was made of aluminum, and the material of the bullet 4 and the incident rod 1 was the same. The diameters of bullet 4, incident rod 1, specimen rod 2 and absorbing rod 3 are all 37 mm, bullet 4 is 80 mm long, incident rod 1 is 1000 mm long, and specimen rod 2 and energy-absorbing rod 3 are 1000 mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com