Span device wire clamp for connecting electric power conductor and electric power device

A technology for power equipment and power wires, applied in conductive connection, electrical component connection, connection, etc., can solve the problems of users' delay in power transmission, large connection resistance, long connection time, etc., to achieve good connection effect and small inventory. , the effect of good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

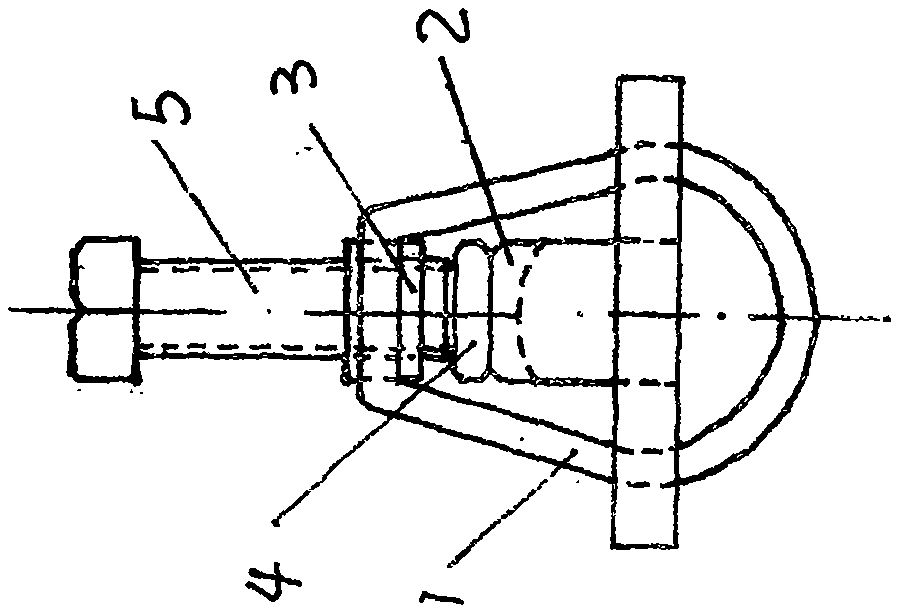

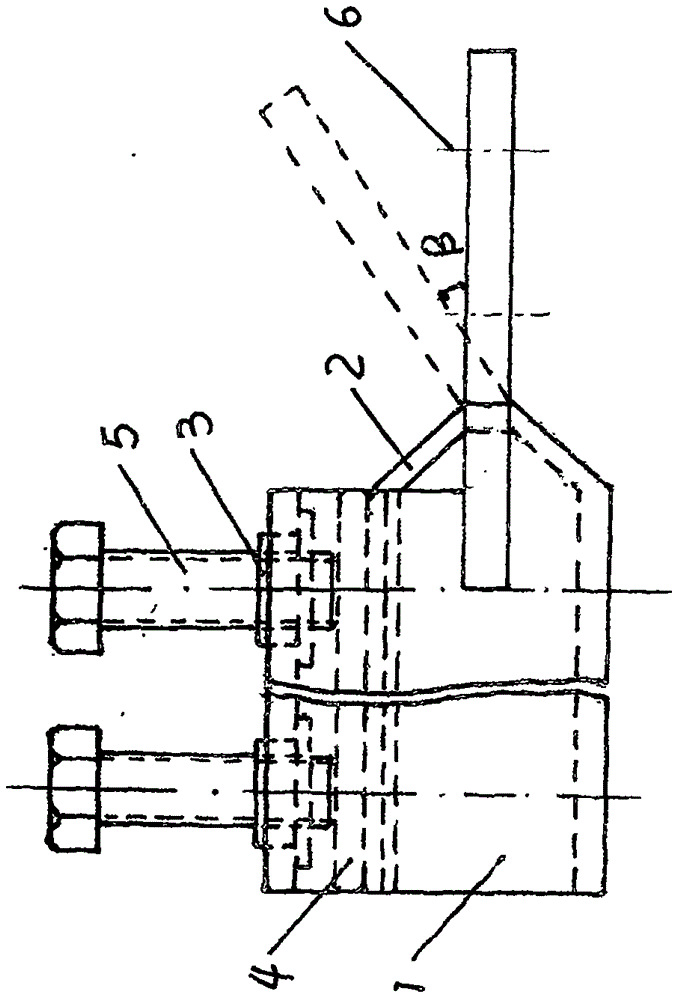

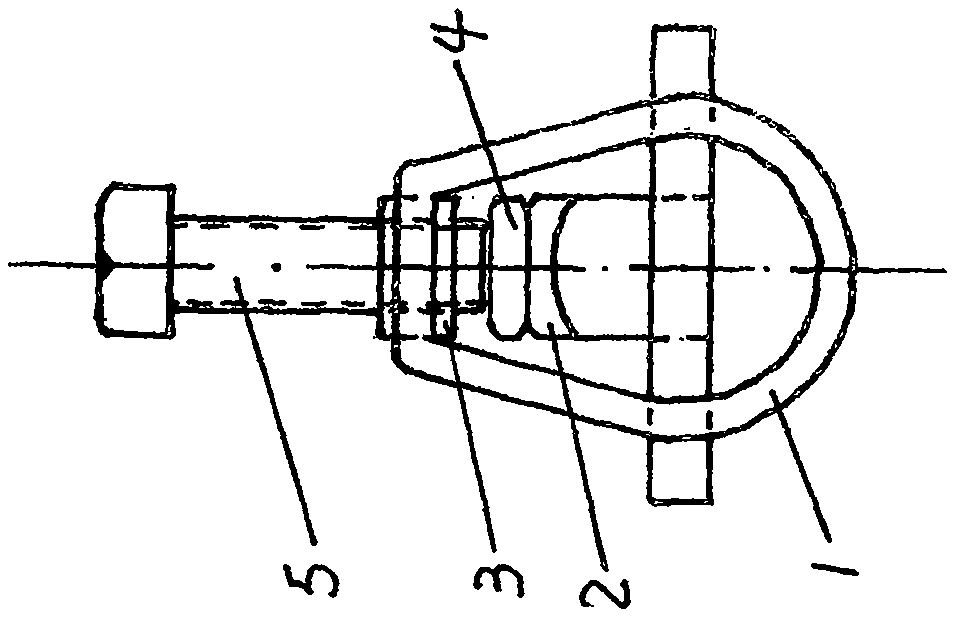

[0028] Figures 1 to 6 As shown in and 11: the span equipment clamp for connecting the power conductor to the power equipment is mainly composed of a threading pipe 1 and a fastening bolt 5. The front part of the threading pipe 1 is a threading pipe body, and the threading pipe body of the threading pipe 1 The rear part of the threading pipe 1 is provided with a connection fixing plate fixedly connected with the threading pipe body, and the installation fixing hole 6 connected with the terminal post of the external electric equipment is arranged on the connection fixing plate. The cross section of the threading pipe body at the front part of the threading pipe 1 is An elliptical ring body with a flat top at the top, a semicircular cavity at the bottom of the elliptical ring body, and a trapezoidal cavity at the top of the elliptical ring body, the fastening bolts 5 are vertically arranged and screwed In the trimming flange nut on the upper top of the trapezoidal cavity, a clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com