Rotary open/close-type tube container

A technology of opening and closing containers, applied in containers, flexible tubular containers, rigid containers, etc., which can solve the problems of leakage of contents and troubles for users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, the present invention will be described in detail with reference to the drawings. The same reference numerals shown in the respective drawings denote the same components.

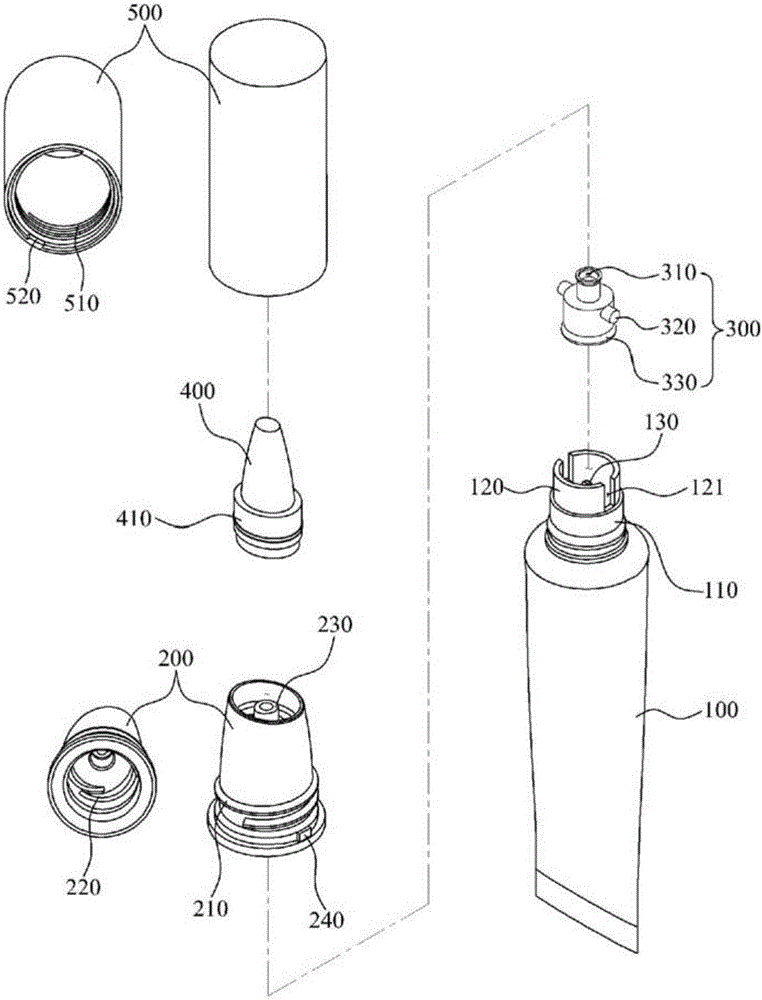

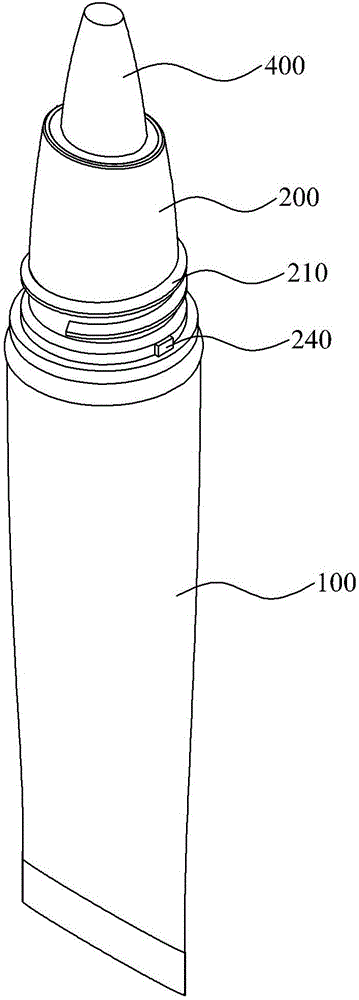

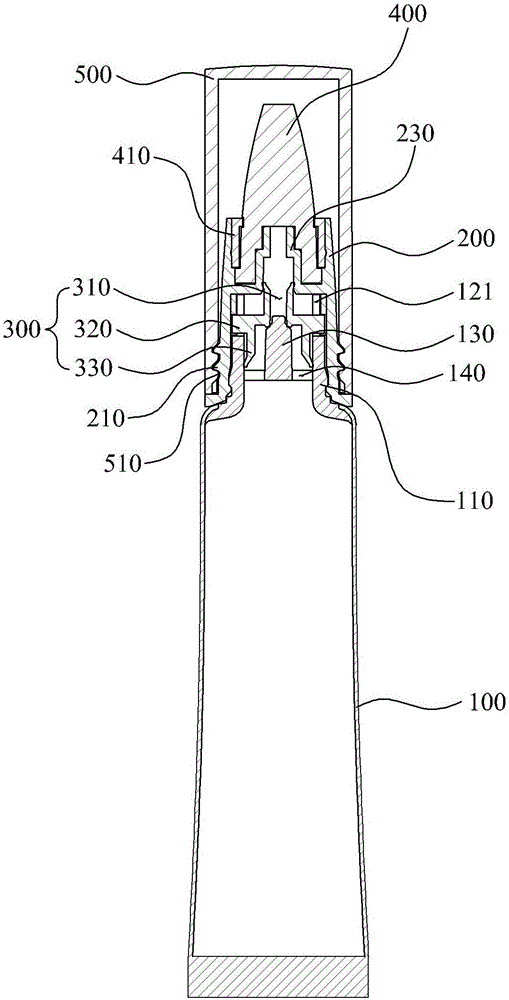

[0026] figure 1 An exploded perspective view showing the structure of the rotary opening and closing type tube container according to the first embodiment of the present invention, figure 2 A combined perspective view showing the structure of the rotary opening and closing type tube container according to the first embodiment of the present invention, image 3 It is a sectional view showing the structure of the rotary opening and closing type tube container according to the first embodiment of the present invention.

[0027] refer to Figure 1 to Figure 3 , according to the first embodiment of the present invention, the rotary opening and closing tube container includes: a container body 100 , a rotary cap 200 , a sealing cap 300 , an applicator 400 and a top cap 500 .

[0028] The ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap