The driving mechanism and the chuck that drive the moving part to move radially back and forth on the mounting seat

A technology of reciprocating movement and driving mechanism, which is applied in the field of workpiece clamping devices, can solve problems affecting the normal use of the chuck, and achieve the effects of simple and reliable mechanical transmission process, accurate and stable position, and stable and reliable mechanical transmission mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

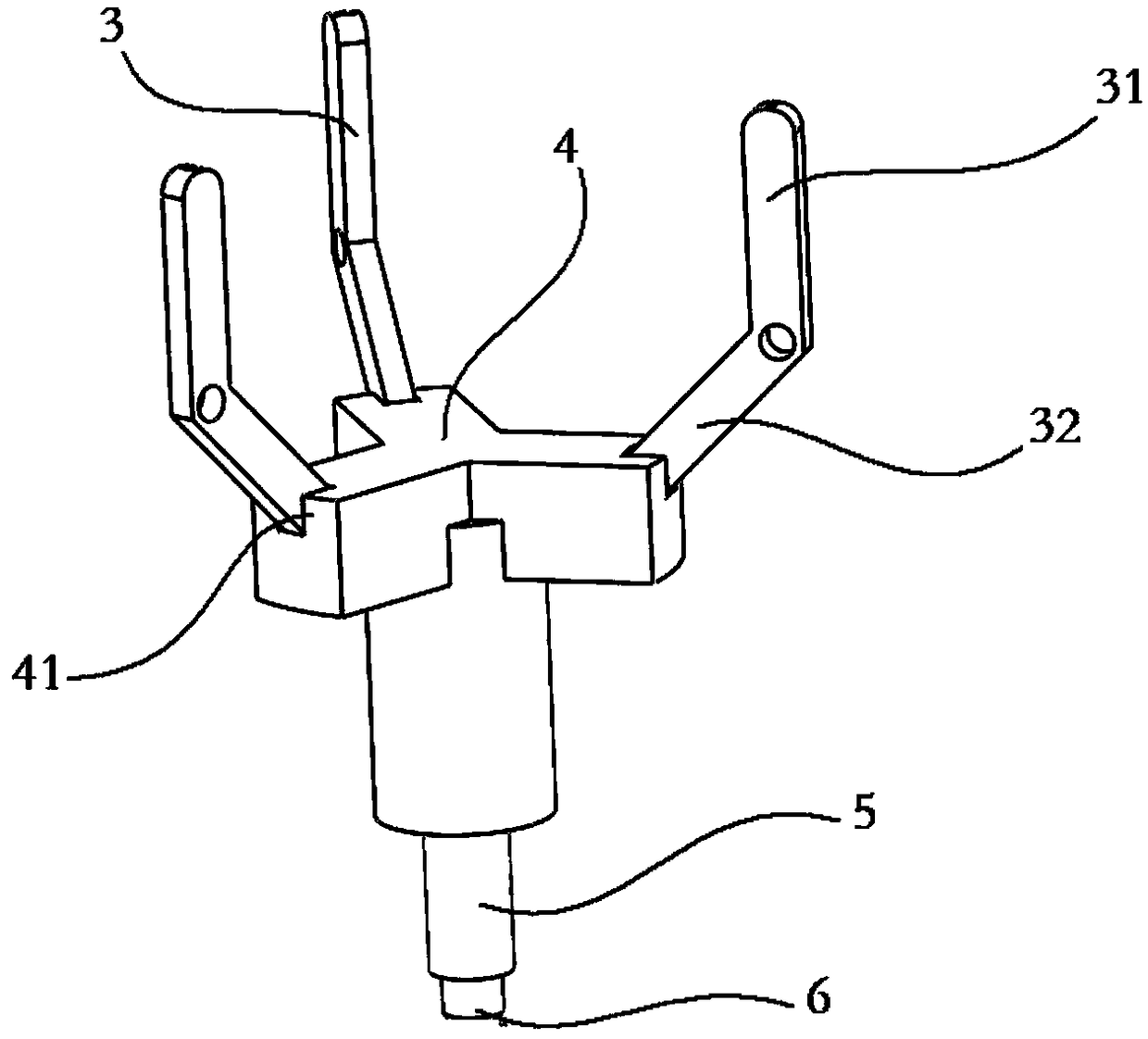

[0041] figure 1 It is a three-dimensional view of the driving mechanism provided in the first embodiment of the present invention for driving the moving part to move radially back and forth on the mounting seat, such as figure 1 Said, the driving mechanism for driving the moving part to move radially back and forth on the mounting seat provided by this embodiment includes: a toggle member, which is rotatably arranged relative to the mounting seat, and is positioned on the moving member corresponding to the toggle member. It rotates in a plane determined by the radial direction and the axial direction of the mounting seat, and is connected with the corresponding moving part; the drive assembly has a toggle connecting portion 41 which is consistent with the distribution of the toggle, so The toggle member is hinged to the corresponding toggle member connecting portion 41, and when the drive assembly moves back and forth in the axial direction of the mounting seat, the toggle member...

Embodiment 2

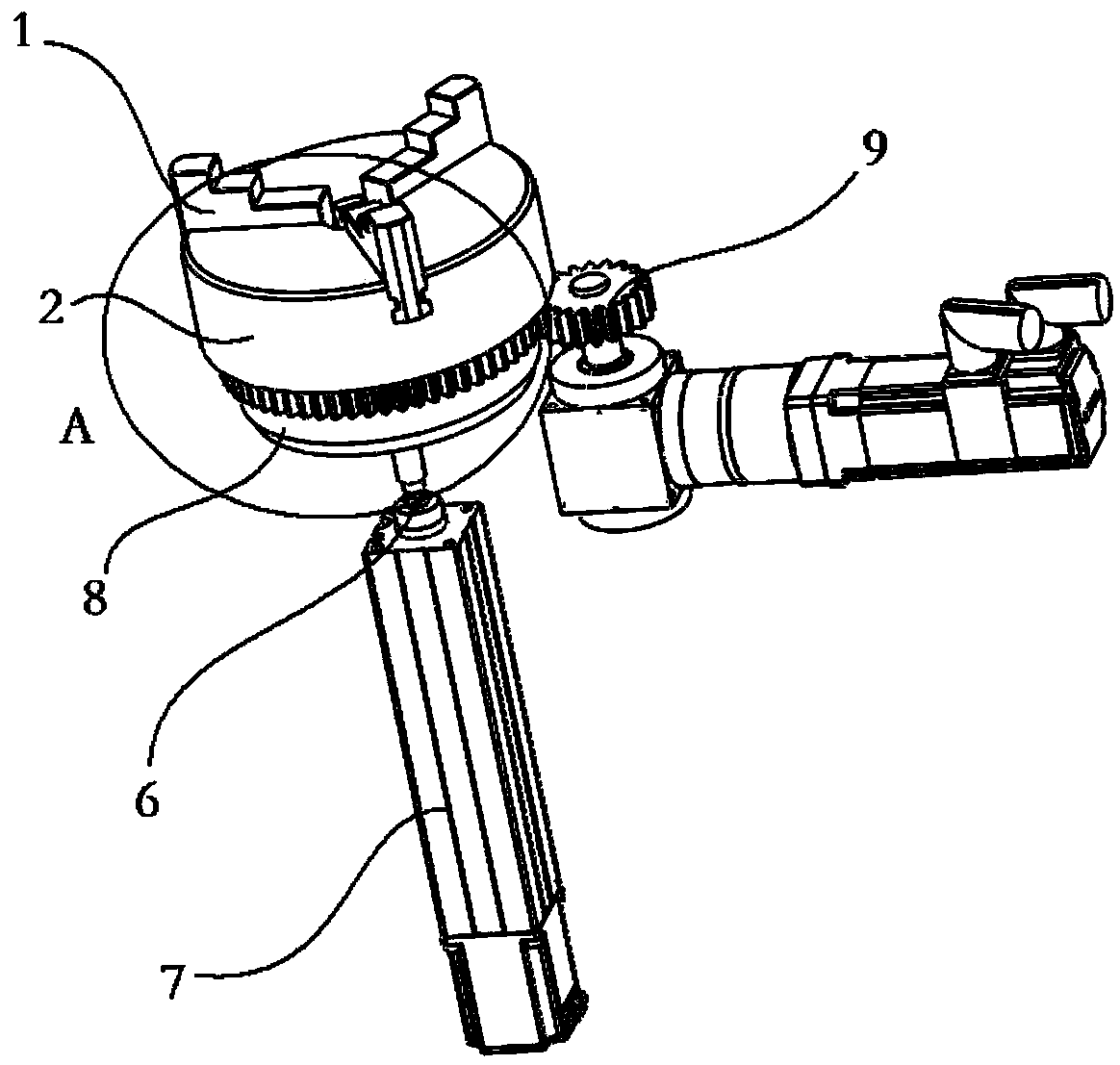

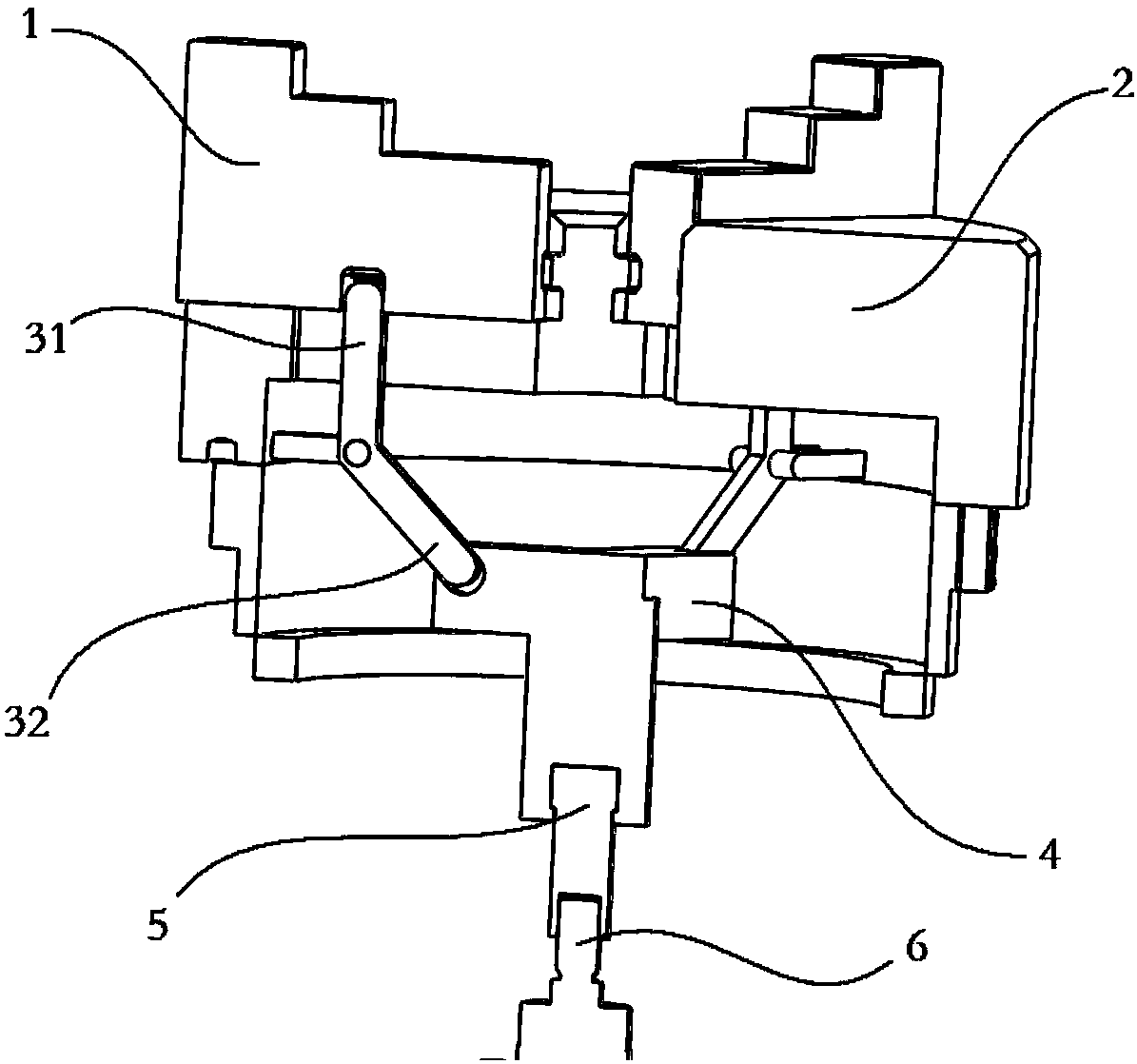

[0048] figure 2 Is a three-dimensional view of the chuck provided in the second embodiment of the present invention; image 3 for figure 2 Sectional view at middle A, such as figure 2 with 3 As shown, the chuck provided in this embodiment includes at least two jaws 1; the chuck body 2 is formed with radial grooves uniformly distributed on the disc surface, and each of the radial grooves is provided with one jaw 1. At least two of the claws 1 near the center of the chuck body 2 form a clamping opening, and the claws 1 can reciprocate along the radial groove to adjust the clamping diameter Size; and the driving mechanism described in the first embodiment for driving the moving part to move radially back and forth on the mounting seat, wherein the shifting part is the claw 1 and the mounting seat is the chuck body 2.

[0049] The driving mechanism is driven by the telescopic power to drive the claw 1 to move radially along the disk surface, and the clamping opening formed by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com