A shock-absorbing processing device for plates

A technology for processing devices and plates, which is applied to machine tools, grinding drives, and metal processing equipment suitable for grinding workpiece planes. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

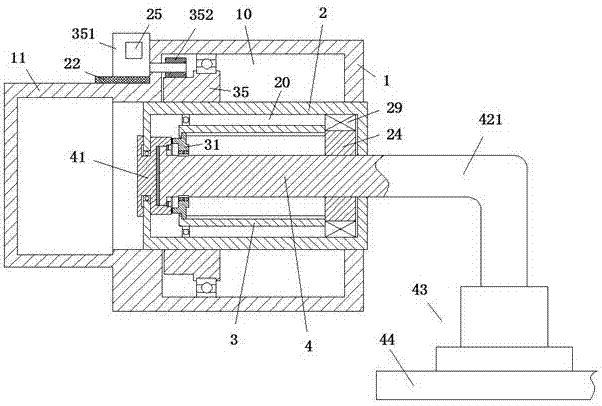

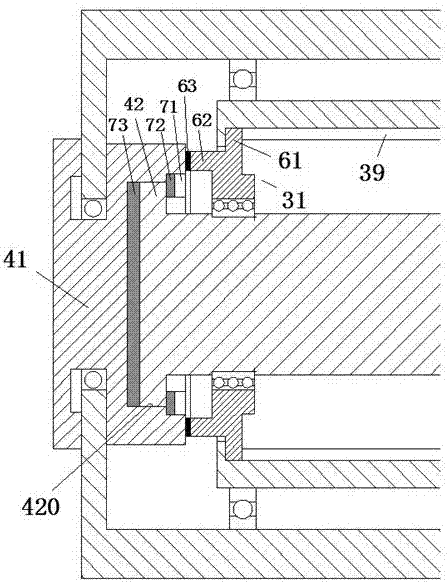

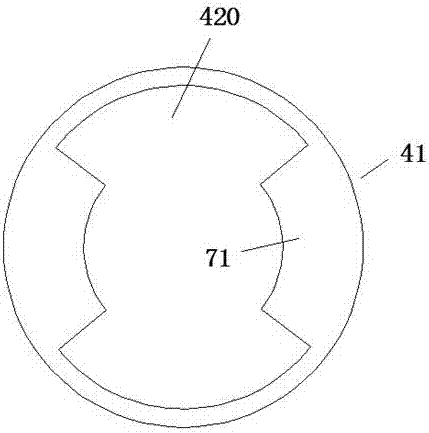

[0009] Combine below Figure 1-3 The present invention will be described in detail.

[0010] According to the embodiment of the present invention, the vibration-absorbing processing device for plate materials includes a housing 1, a gear drive motor 351 installed on the housing 1, and is installed on the housing 1 through bearings to be rotatable in the circumferential direction and fixed in the axial direction. The threaded sleeve 35 in the chamber 10 of the housing 1, the threaded sleeve 2 cooperating with the internal thread of the threaded sleeve 35, and the threaded sleeve 2 axially fixedly installed in the inner cavity 20 of the threaded sleeve 2 The hollow shaft motor 29, the internal threaded block 24 which is rotatable and axially fixed by the hollow shaft motor 29 and the internal screw member 4 threaded with the internal threaded block 24, wherein the gear drive motor 351 The gear 352 of the power connection is engaged with the threaded tooth sleeve 35, the threade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com