Fish suction pipe device for a fish suction pump

A technology of fish pump and main body, which is applied in the field of fish suction pipe device for fish suction pump, which can solve the problems of low fish suction efficiency, too large fish suction pipe, unfavorable fish suction into the tank, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

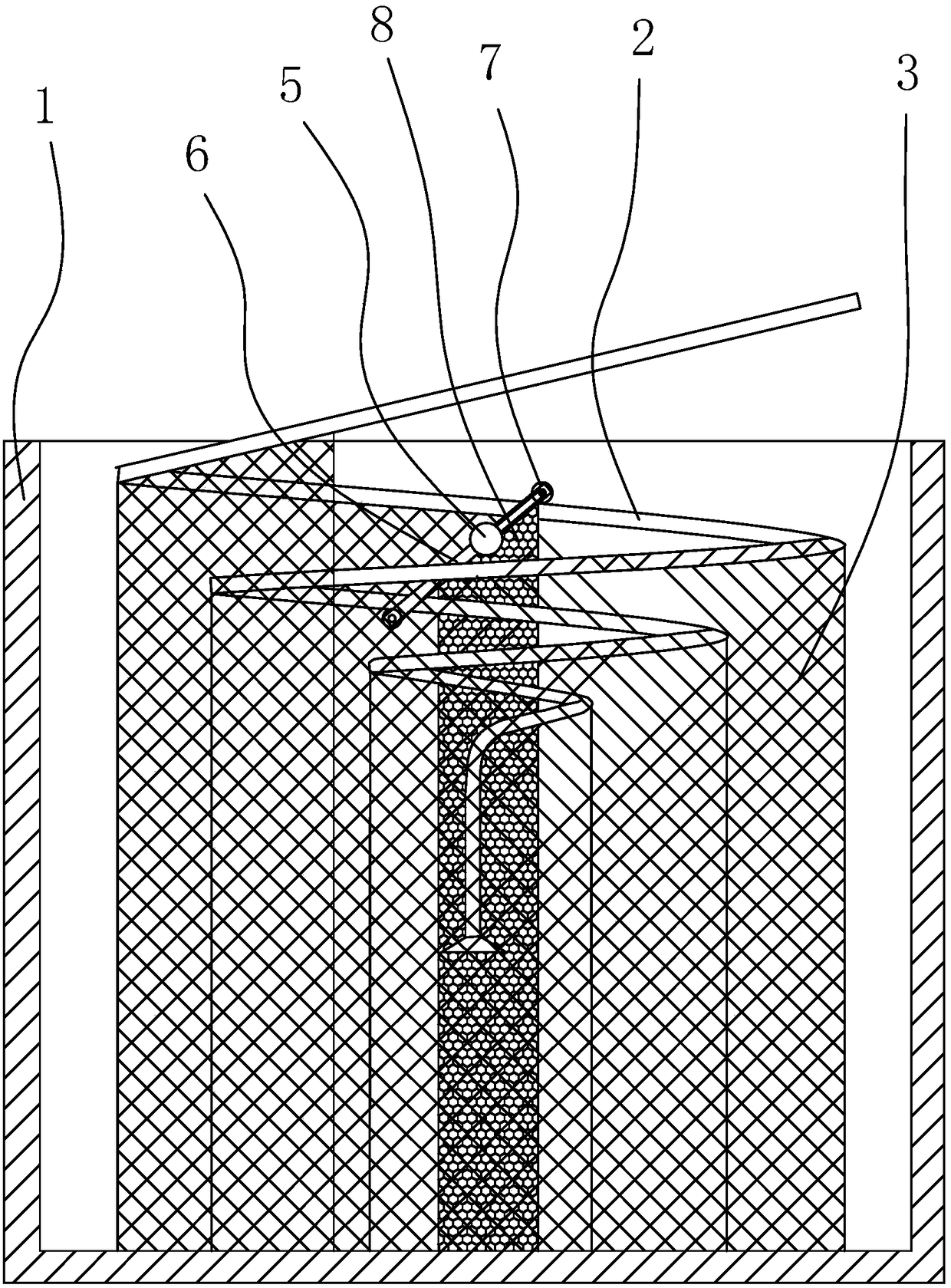

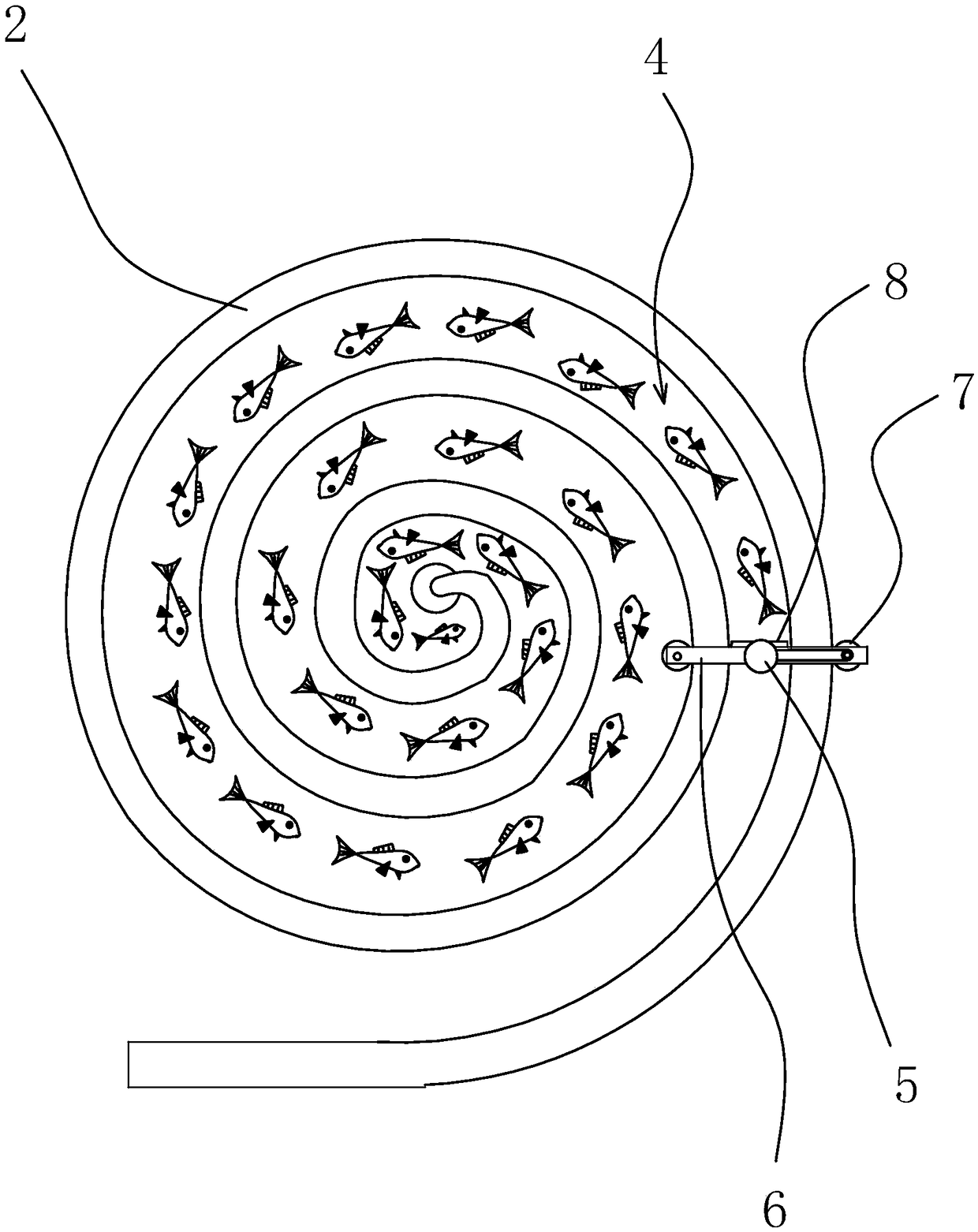

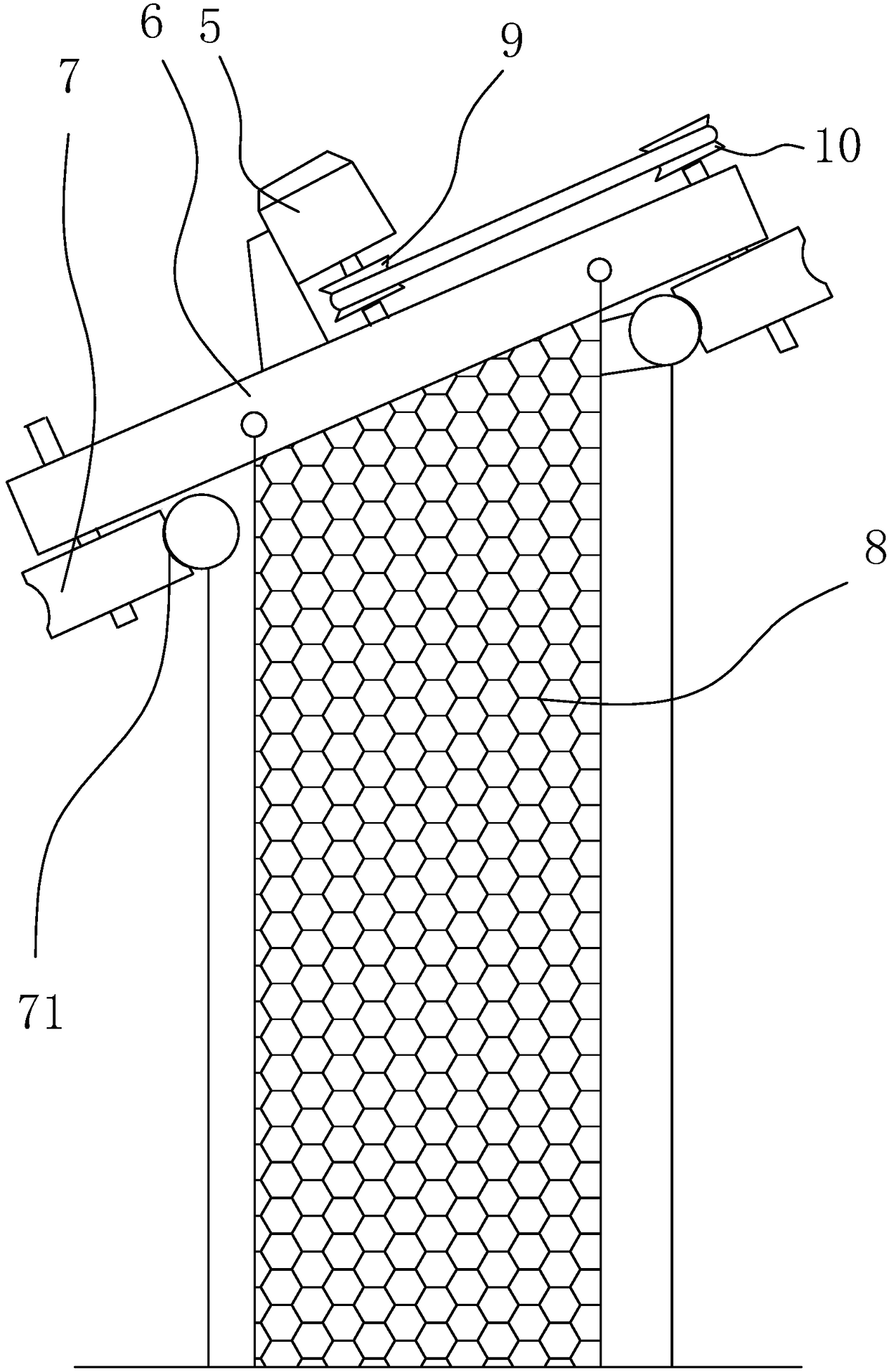

[0021] Such as Figure 1-3 Shown, this fish-suction pump uses the fish-suction pipe device, comprises the fish-suction pipe body 2 that can stretch into net cage 1, motor 5, connecting rod 6 and two guide wheels 7 that are connected to connecting rod 6 two ends in rotation respectively. The fish suction pipe body 2 is in a spiral shape, and the fish suction pipe body 2 is hung with a curtain body 3 along the spiral direction, and a spiral channel 4 is formed between the curtain bodies 3, and the connecting rod 6 is located above the spiral channel 4, so that The connecting rod 6 is hung with a net-shaped stop body 8, the stop body 8 is located in the spiral channel 4, and the two guide wheels 7 are respectively against the side walls of the fish suction pipe body 2 on both sides of the spiral channel 4, The motor 5 is arranged on the connecting rod 6, and the motor 5 is covered with a waterproof sealing shell, and the motor 5 and the guide wheel 7 are connected by a transmissi...

Embodiment 2

[0026] The structure of this embodiment is basically the same as that of Embodiment 1, except that the transmission mechanism includes a driving gear connected to the rotating shaft of the motor 5 and a driven gear connected to one of the guide wheels 7, the driving gear and the driven gear Mesh. The rotating shaft of motor 5 rotates and then drives the driving gear to rotate, and the driven gear meshed with it rotates accordingly, and the guide wheel 7 connected to the driven gear rotates coaxially thereupon, thereby being able to roll along the fish suction pipe body 2, and then drive Another guide wheel 7 can also roll along the fish suction pipe body 2, so that the baffle body 8 moves forward, and the fish is driven to the fish suction mouth of the fish suction pipe body located at the center of the net cage 1, thereby improving the efficiency of fish suction .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com