A continuous anode carbon block and its processing method

A technology of anode carbon block and processing method, which is applied in the field of metallurgy, can solve the problems of large processing capacity, high quality requirements of special adhesive paste, and generation of residual electrodes, so as to reduce electrolysis energy consumption, improve resource utilization, and reduce electromagnetic field fluctuations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

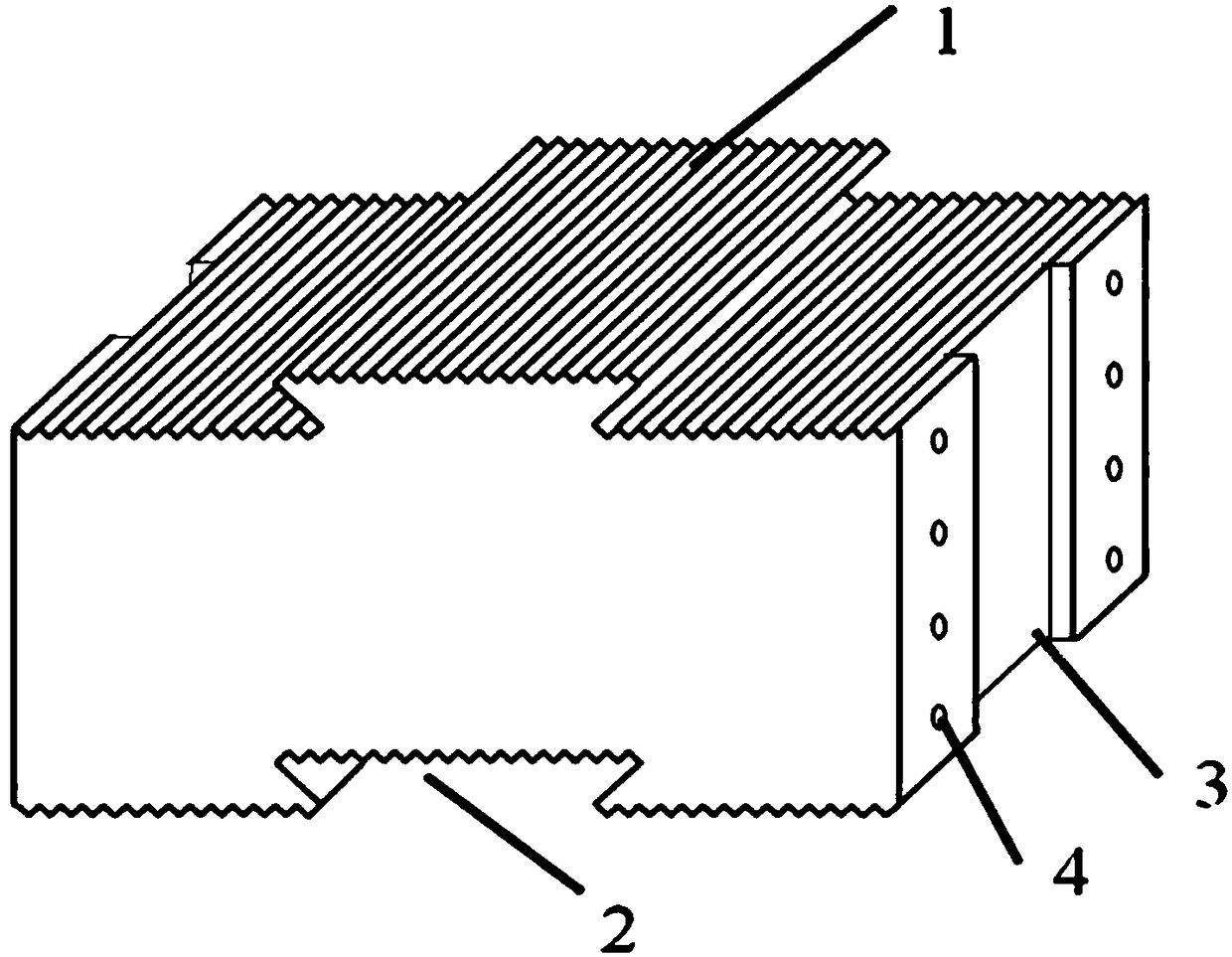

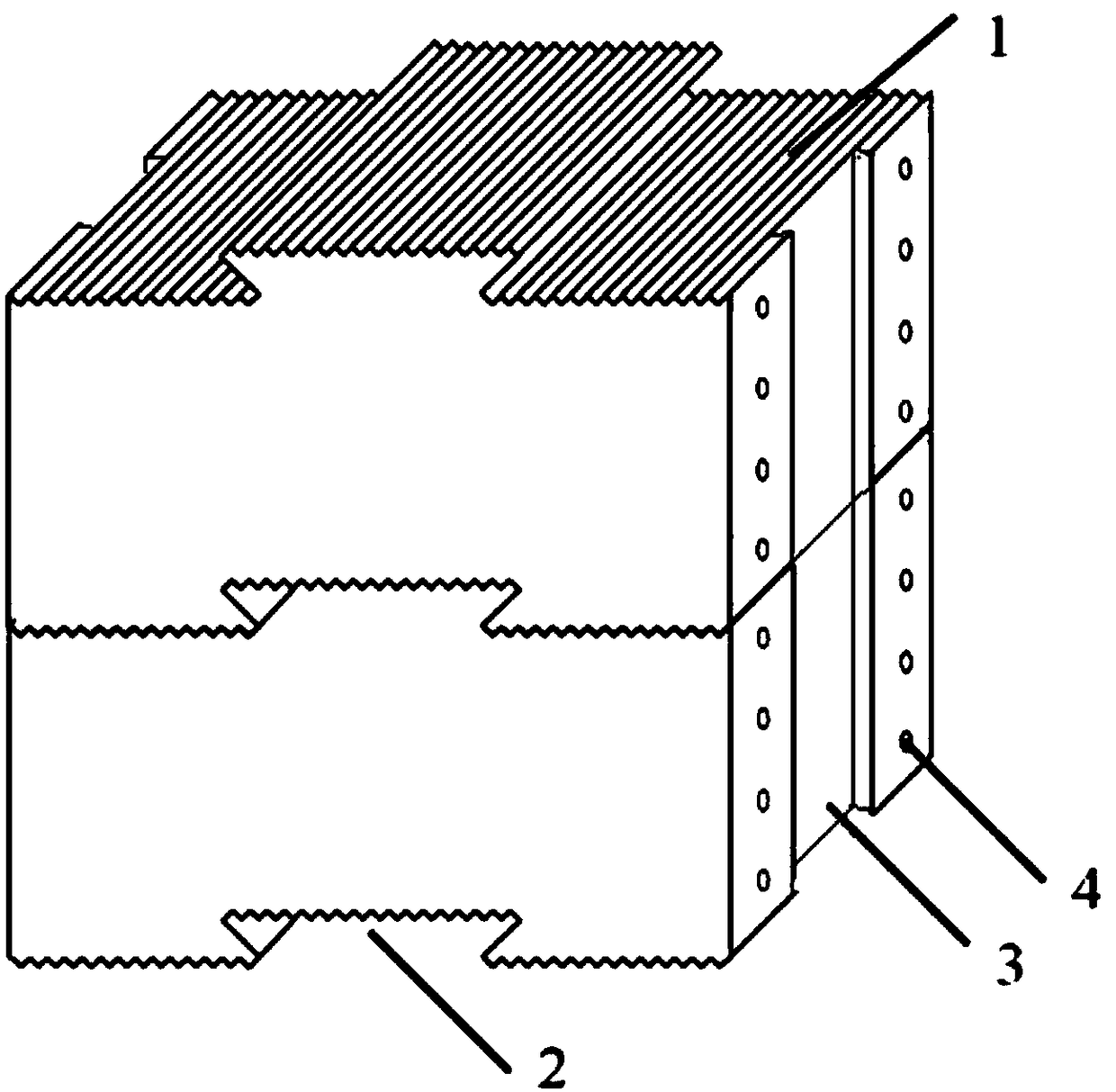

[0044] A continuous anode carbon block with a rectangular parallelepiped structure, with a clamping block 1 on the upper surface and a clamping groove 2 on the lower surface, both of which are sawtooth corrugated surfaces; Road 3, both sides of the slideway are fixed connection areas.

[0045] The clamping block is a dovetail block; the clamping slot is a dovetail groove.

[0046] The fixed connection area is a plane fixed connection area 4 provided with a fixed connection hole; the fixed connection hole is a row of round holes, and the fixed connection button of the mobile crawler used in conjunction with the fixed connection hole is snap-fitted.

[0047] A group of slideways 3 on the opposite side of the side are sliding conductive grooves, which are used in conjunction with sliding conductive plates.

[0048] In use, several continuous anode carbon blocks are used in combination, and two adjacent continuous anode carbon blocks are clamped and fixed through dovetail blocks ...

Embodiment 2

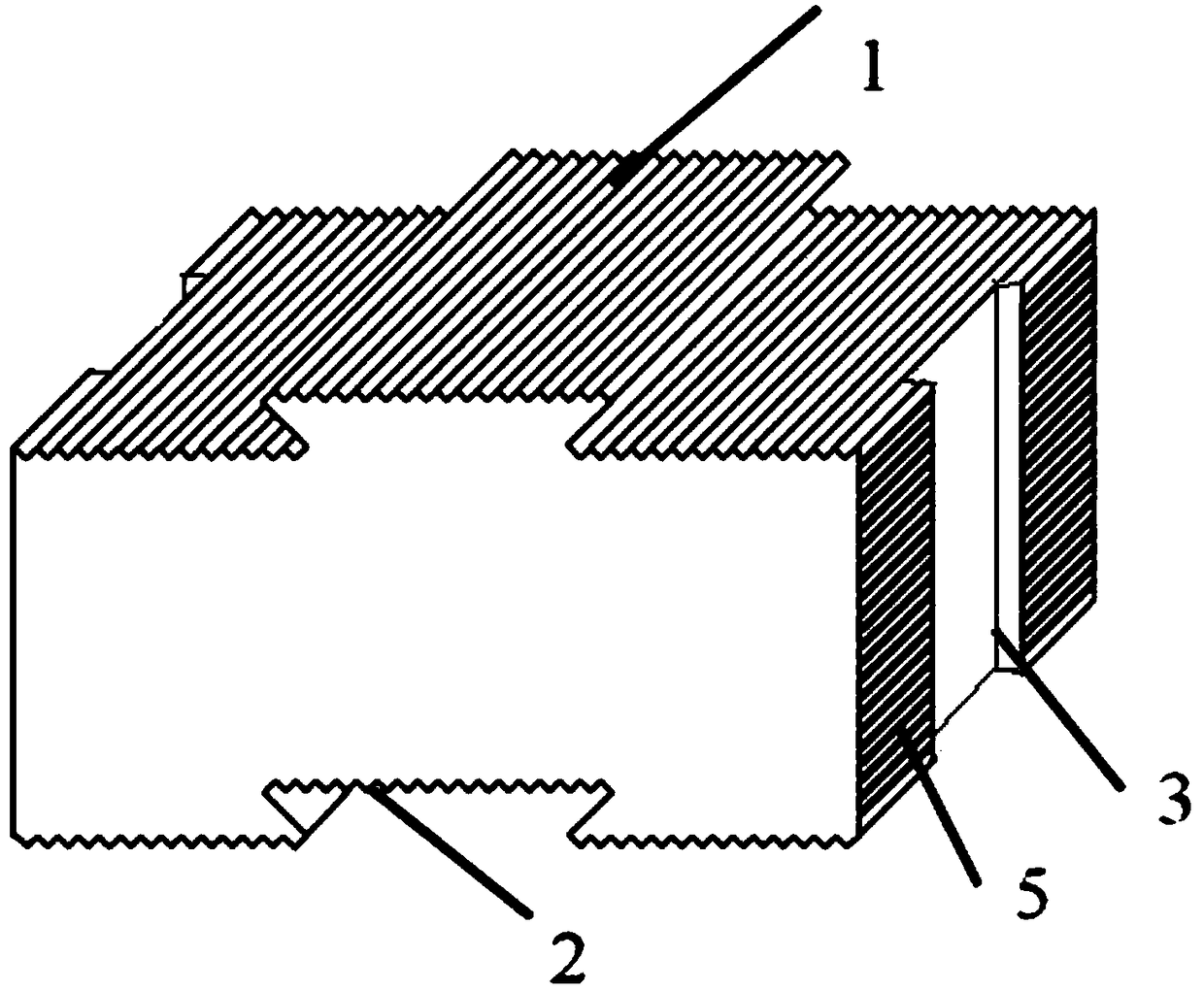

[0063] A continuous anode carbon block, which is a cube structure. The upper surface is provided with a clamping block 1, and the lower surface is provided with a clamping groove 2. Both the upper surface and the lower surface are sawtooth corrugated surfaces; Road 3, both sides of the slideway are fixed connection areas.

[0064] The clamping block is a dovetail block; the clamping slot is a dovetail groove.

[0065] The fixed connection area is a sawtooth corrugated surface 5; the sawtooth corrugated surface is a through sawtooth corrugated surface, and the sawtooth corrugated surface of the moving machine crawler used in conjunction with it is snap-fitted with the sawtooth corrugated surface of the fixed connection area;

[0066] A group of slideways 3 on the opposite side of the side are sliding conductive grooves, which are used in conjunction with sliding conductive plates.

[0067] In use, several continuous anode carbon blocks are used in combination, and two adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com