Treatment agent for polyester-based synthetic fiber, method for treating polyester-based synthetic fiber, and polyester-based synthetic fiber

A synthetic fiber and treatment agent technology, applied in fiber treatment, single-component polyester rayon, textiles and papermaking, etc., can solve the problems of emulsification stability, heat resistance, antistatic performance, and scum accumulation resistance. , to achieve the effect of satisfying the emulsification stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

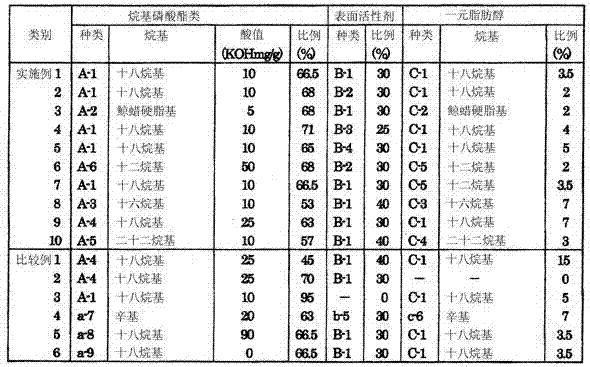

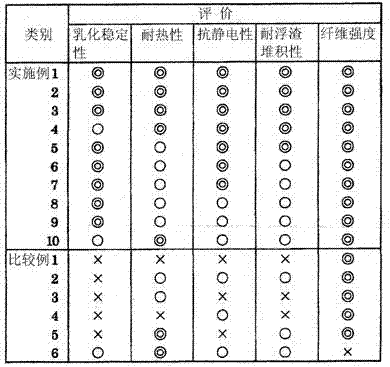

[0031] Hereinafter, in order to make the structure and effect of this invention concrete, an Example etc. are given, However, this invention is not limited to these Examples. It should be noted that in the following examples and comparative examples, parts mean parts by mass, and % means % by mass.

[0032] Test category 1 (preparation of aqueous solution of treatment agent for polyester-based synthetic fibers)

[0033] ・Preparation of an aqueous solution of a treatment agent for polyester-based synthetic fibers (Example 1)

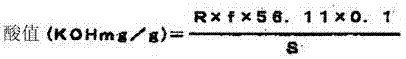

[0034] 66.5 parts of octadecyl phosphate potassium salt (acid value 10KOHmg / g) (A-1), α-nonylphenyl-ω-hydroxyl (polyoxyethylene) (n=10, n is ethylene oxide unit Quantity, the same below) and 70:30 (mass ratio) mixture (B-1) 30 parts of the mixture (B-1) of α-dodecylamino-ω-hydroxyl (polyoxyethylene) (n=10), and stearyl alcohol ( C-1) 3.5 parts were put into a beaker, mixed well, and half of the prescribed amount of ion-exchanged water heated to 80° C. w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com