Automotive automatic shift cable assembly and quick assembly method

A technology of automatic shifting and assembly methods, which is applied in the direction of transmission device control, linear motion shafts, flexible shafts, etc., can solve the problems of transmission comfort and safety, increase the workload of workers, and inaccurate operations, etc., to achieve applicable The effect of wide range, avoiding unsmooth transmission, and adjustable overall length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

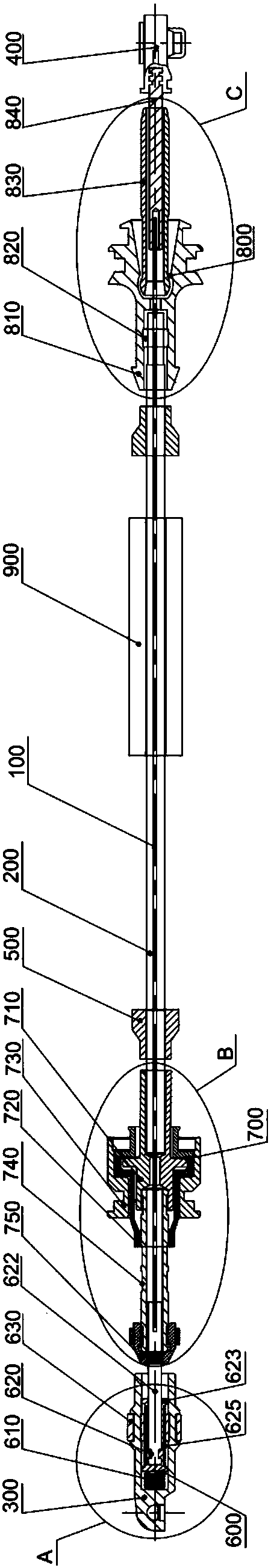

[0060] Such as figure 1 As shown, this embodiment discloses a cable assembly for automatic shifting of automobiles, including a steel wire rope 100, a protective tube 200, a first connector 300, a second connector 400, a shock absorber 500 and a length adjustment mechanism 600, and the wire rope 100 slides through the protection tube 200, the first end of the wire rope 100 passes through one end of the protection tube 200, the second end of the wire rope 100 passes through the other end of the protection tube 200, and the first connector 300 passes through the length adjustment mechanism 600 is connected to the first end of the wire rope 100 , and the second connector 400 is connected to the second end of the wire rope 100 .

[0061] Wherein, the damping block 500 is two pieces, and the specific structure is as follows: figure 1 As shown, the two ends of the protection tube 200 are respectively fixed on the two ends of the protective tube 200 through glue bonding sleeves. The...

Embodiment 2

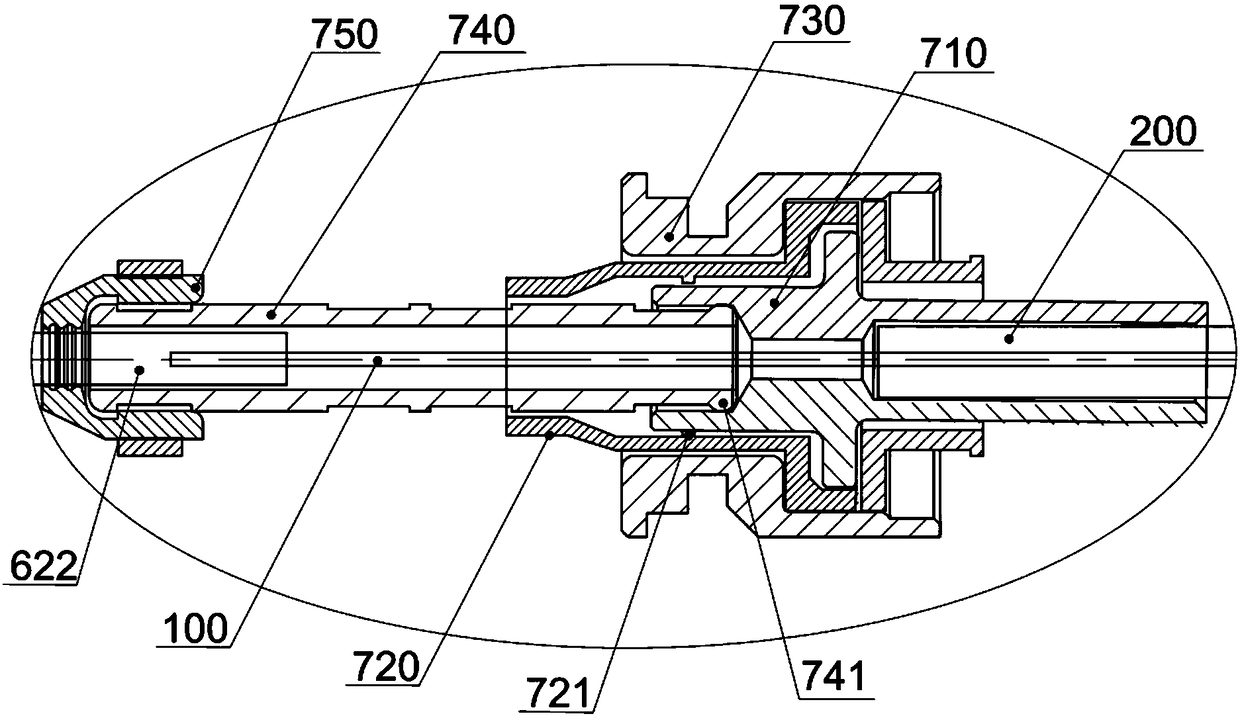

[0075] This embodiment proposes a quick assembly method for an automobile automatic shift cable assembly. Wherein, the automatic shift cable assembly of the automobile is as follows: figure 1 As shown, it includes a steel wire rope 100 , a protective pipe 200 , a first connector 300 , a second connector 400 , a shock absorber 500 , a length adjustment mechanism 600 , a first protective pipe joint mechanism 700 and a second protective pipe joint mechanism 800 .

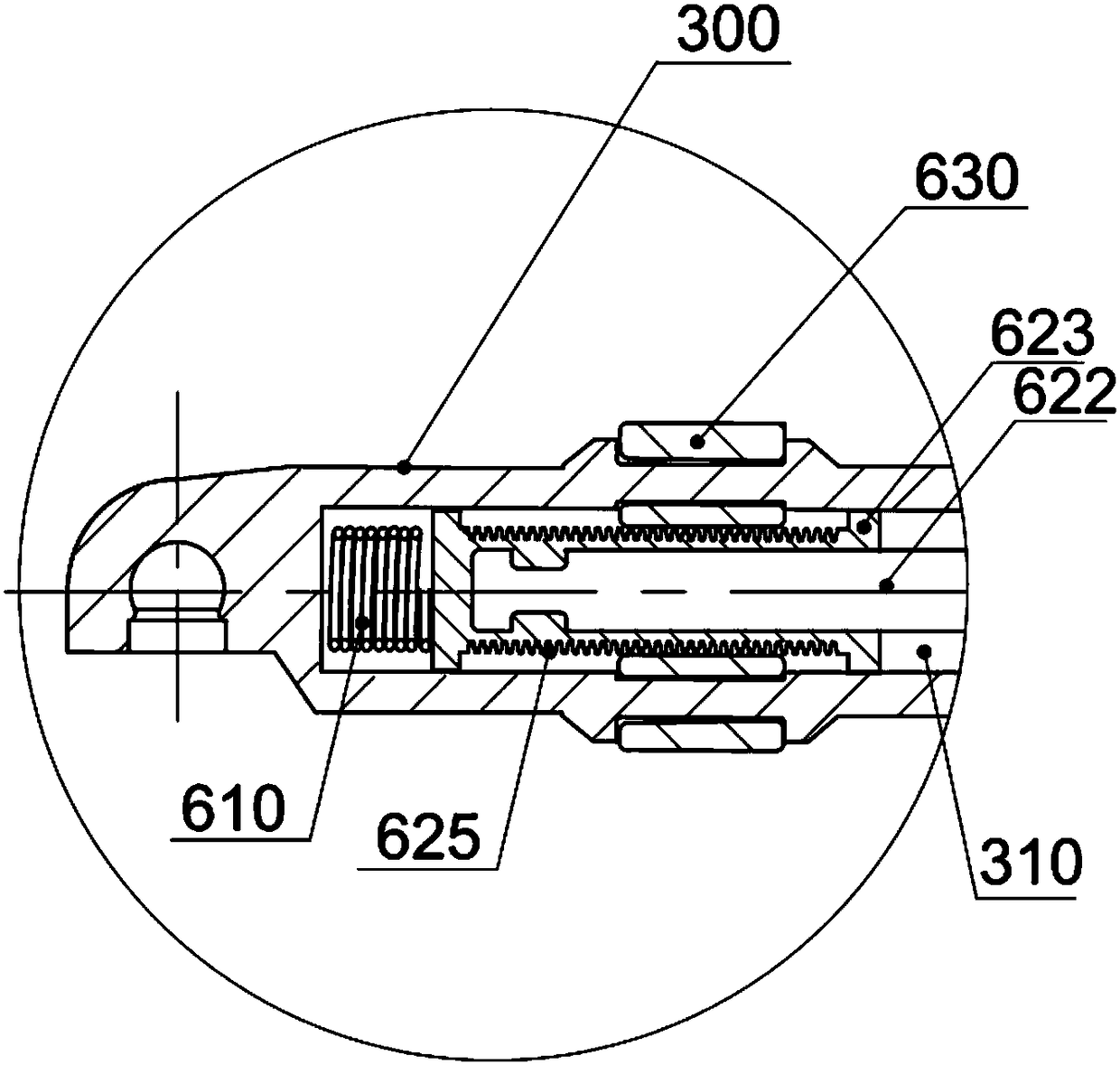

[0076] The length adjustment mechanism 600 of this embodiment is as figure 2 As shown, it includes an adjustment spring 610 , an adjustment screw 620 and an adjustment locking block 630 .

[0077] One end of the first connector 300 of this embodiment is formed as Figure 5 The accommodating groove 310 for accommodating the adjusting spring and the adjusting screw is shown, and the side of the first connector 300 forms a socket 320 for inserting the adjusting lock block, and the socket 320 is arranged in the accommod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com