Replaceable ignition flame radial injection device used at high temperature

A flame injection and injection device technology, which is used in civil, aerospace, ignition and combustion fields, can solve the problems of difficult replacement, insufficient ignition flame injection capability, etc., and achieves the effects of favorable diffusion combustion, improved ignition reliability, and shortened ignition delay.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

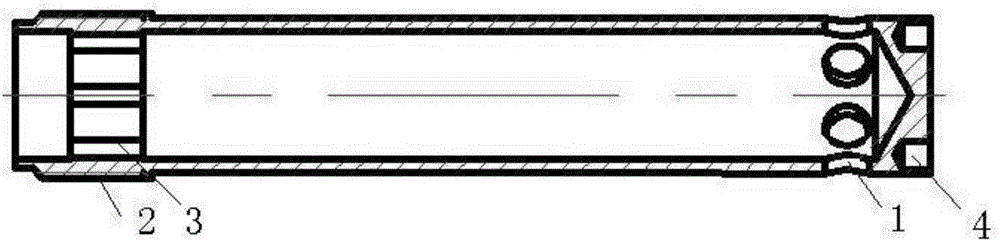

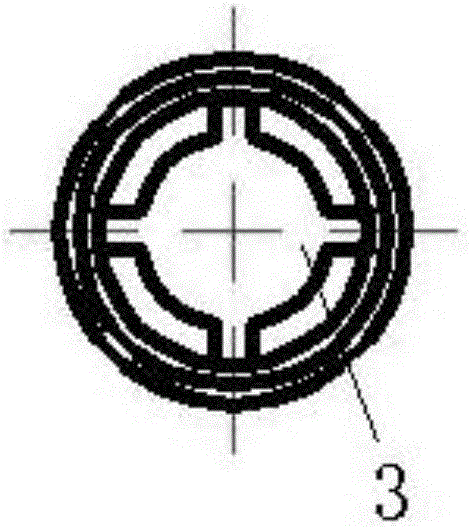

[0010] Such as figure 1 , 2 As shown, a replaceable ignition flame radial injection device for high temperature use includes a flame injection hole 1, a connecting thread 2, a cross groove 3, and an installation process hole 4; the device communicates with the external The device is connected, and the interior of the same axial position as the connecting thread 2 is a cross groove 3, and a flame injection hole 1 is provided near the exit of the device; a process hole 4 is installed outside the exit; before the test, insert the installation process hole 4 through a tool And install the device in related devices through the connecting thread 2. During the test, the flame enters from the entrance and sprays flames around through the flame injection hole 3. After the test, the device can be disassembled by inserting the cross groove through the tooling. The flame injection holes 1 are radially distributed, and the number is 6.

[0011] The ignition flame is injected outward thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com