A high-voltage AC vacuum contactor

A vacuum contactor and high-voltage AC technology, applied in high-voltage air circuit breakers, high-voltage/high-current switches, electrical components, etc., can solve the problems of easy heating of coils and slow closing speed, and achieve the effect of fast contact speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

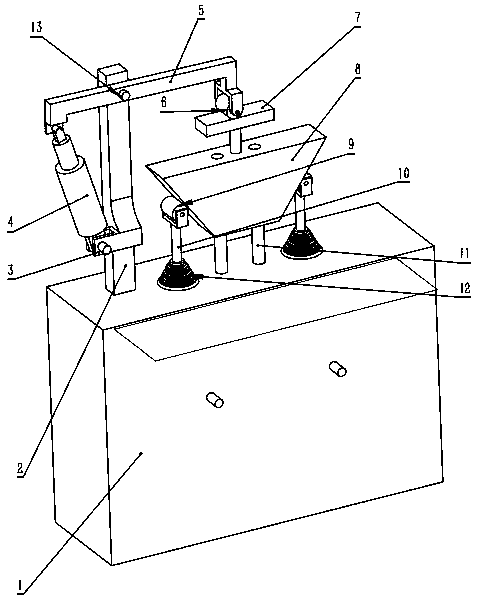

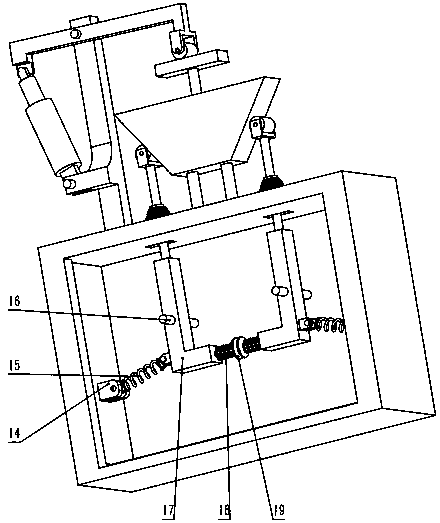

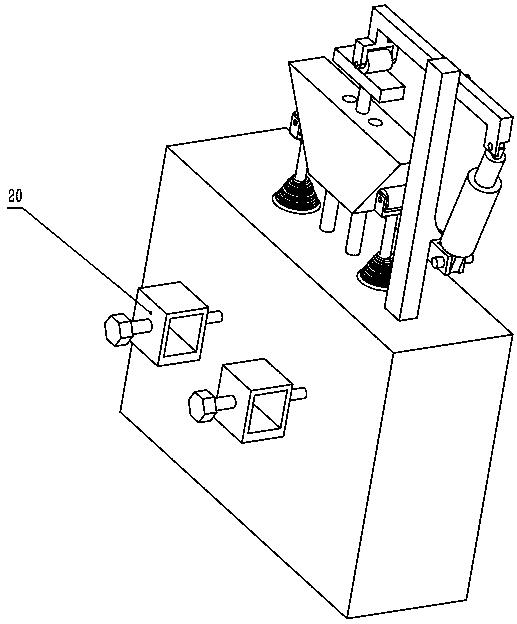

[0013] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a high-voltage AC vacuum contactor includes a vacuum chamber 1, a mounting frame 2, a hinge support A3, a cylinder 4, a connecting rod 5, a roller A6, a flat plate 7, a trapezoidal slider 8, 2 rollers B, 2 Swing rod 10, 2 guide posts 11, 2 metal bellows 12, column pin A13, 2 hinge supports B14, 2 extension springs 15, 2 copper column pins 16, 2 right-angle conductive rods 17, 2 Compression spring 18, 2 moving contacts 19, 2 terminals 20, characterized in that: the vacuum chamber 1 is a vacuum-tight box made of insulating material, and 2 copper pins 16 are installed in the box, One end of each copper stud pin 16 that exposes the outside of the vacuum chamber 1 is connected with a connection terminal 20, one of which is used as an input end, and the other is used as an output end; There are 2 square holes on the top of the vacuum chamber 1; the right-angle conductive rod 17 is made of red copper material, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com