High frequency response relay

A relay and high-frequency response technology, applied in the field of high-frequency response relays, can solve the problems of low response frequency, poor elasticity, fatigue cracks, etc., and achieve the effect of high response frequency and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

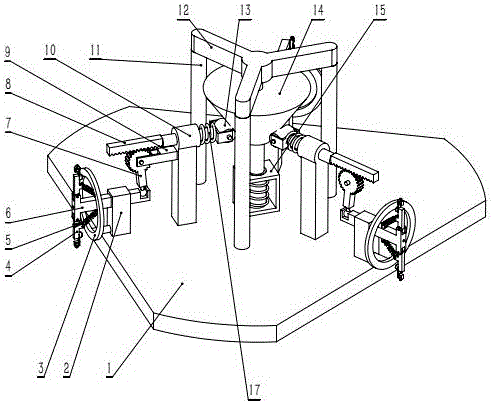

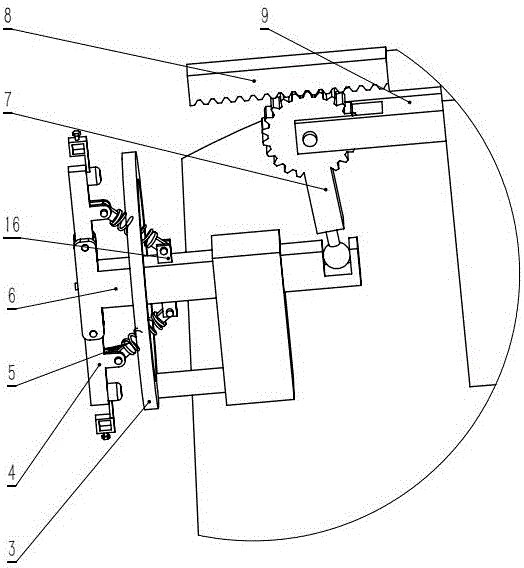

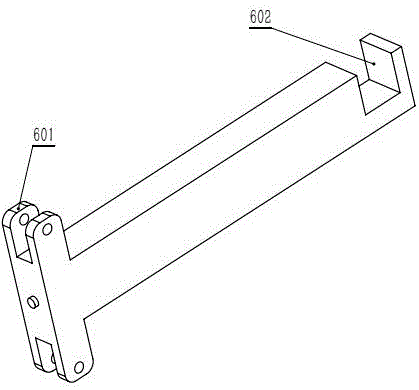

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a high-frequency response relay includes a base plate 1, three uprights 11, a tripod 12, a tapered slider 14, a push-pull electromagnet 15, and three contact units, and is characterized in that: the three uprights 11 Vertically installed above the bottom plate 1, a tripod 12 is installed above the column 11, and a vertical cylindrical shaft is arranged in the center of the tripod 12. The center of the tapered slider 14 has a round hole and passes through This round hole is installed on the cylindrical shaft, its small end is on the bottom, and the big end is on the top. The tapered slider 14 can slide up and down, and its sliding is controlled by the push-pull electromagnet 15. The shell of the push-pull electromagnet 15 is fixed on the bottom plate 1. , the armature of the push-pull electromagnet 15 is connected to the bottom of the tapered slider 14;

[0016] The three contact units are eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com