Mechanical changer for changing end effectors

A mechanical and damper technology, which is applied in the field of mechanical replacement devices, can solve problems such as unsatisfactory bonding strength, hazards to replacement device staff, and inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

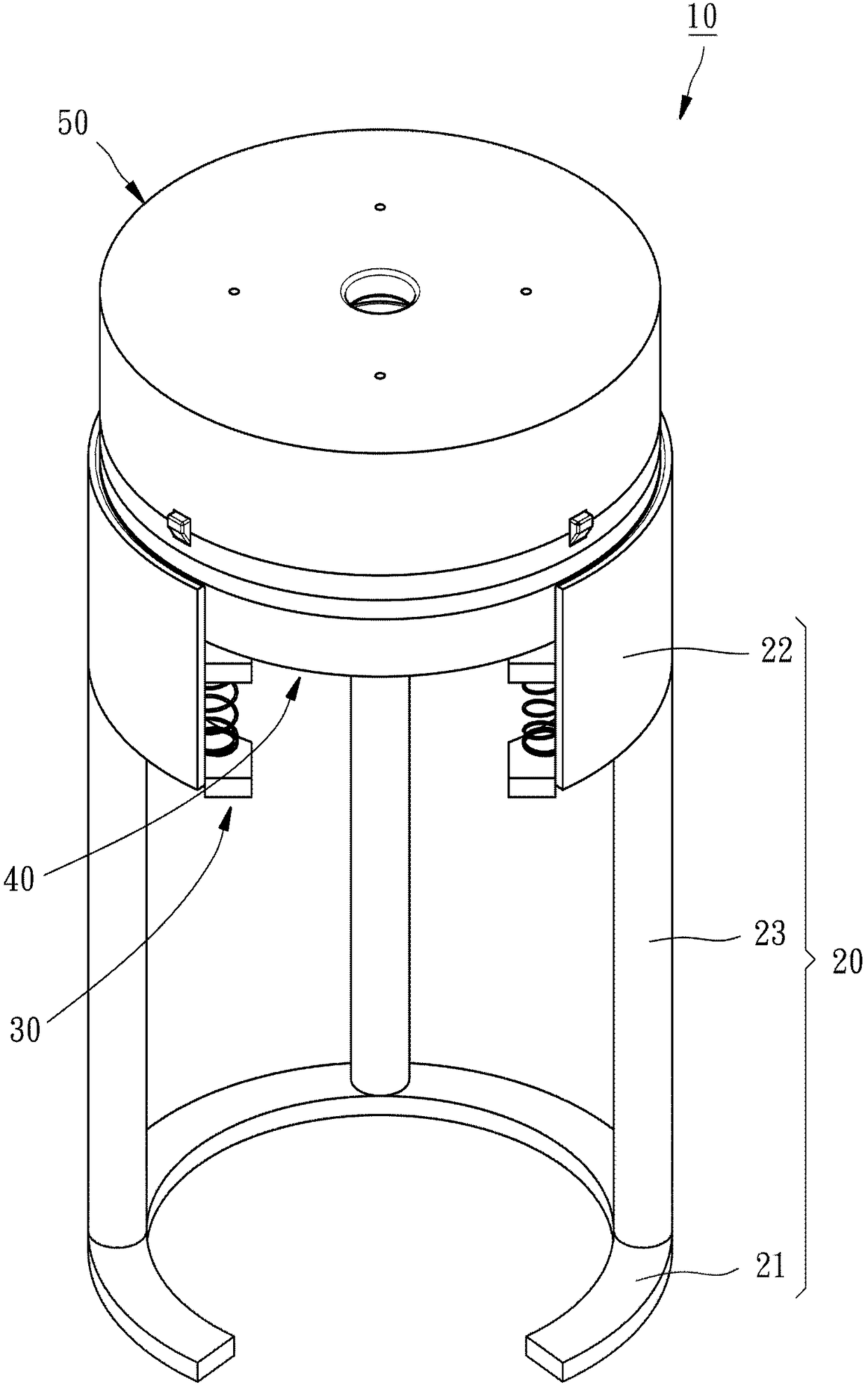

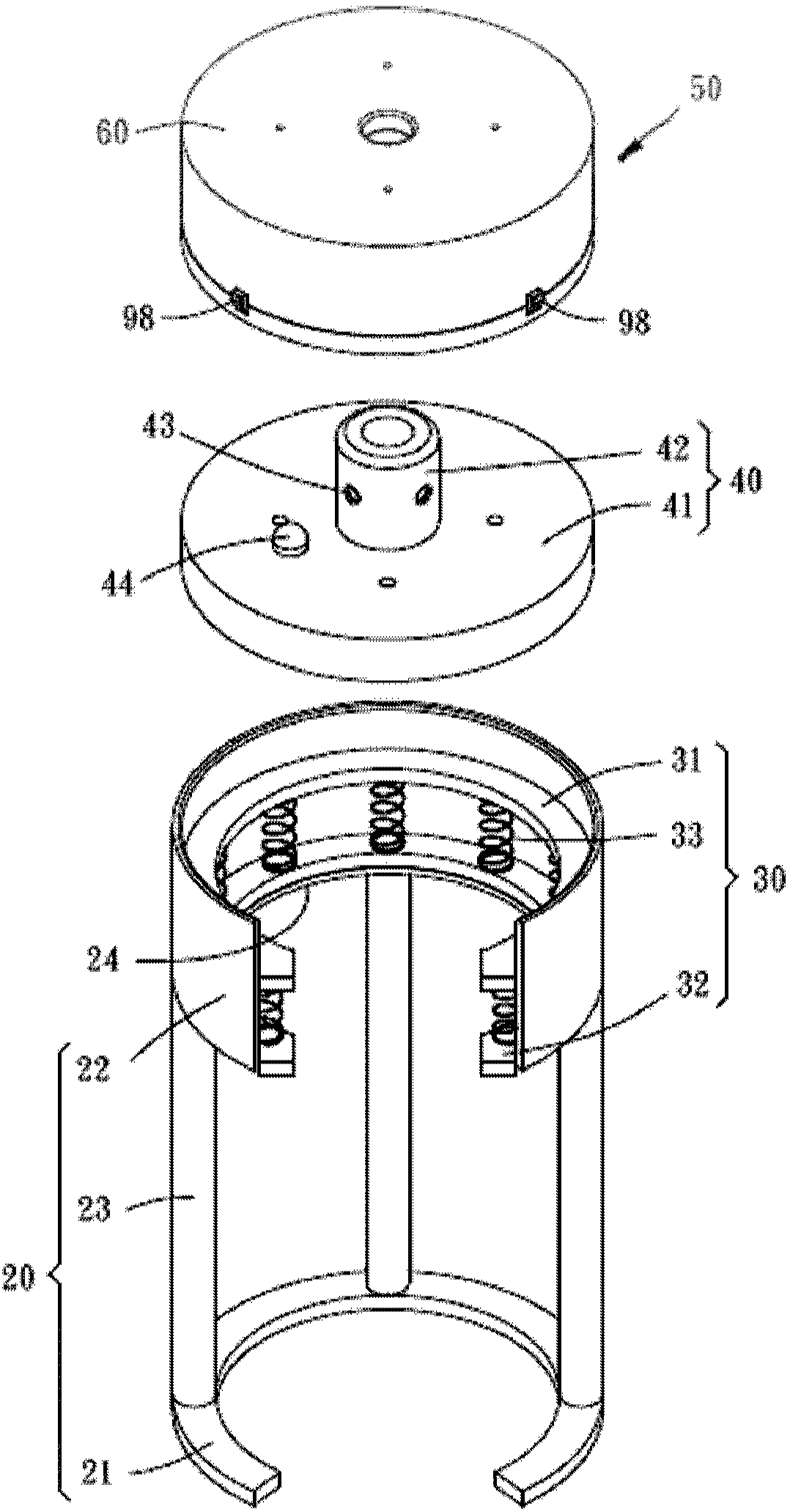

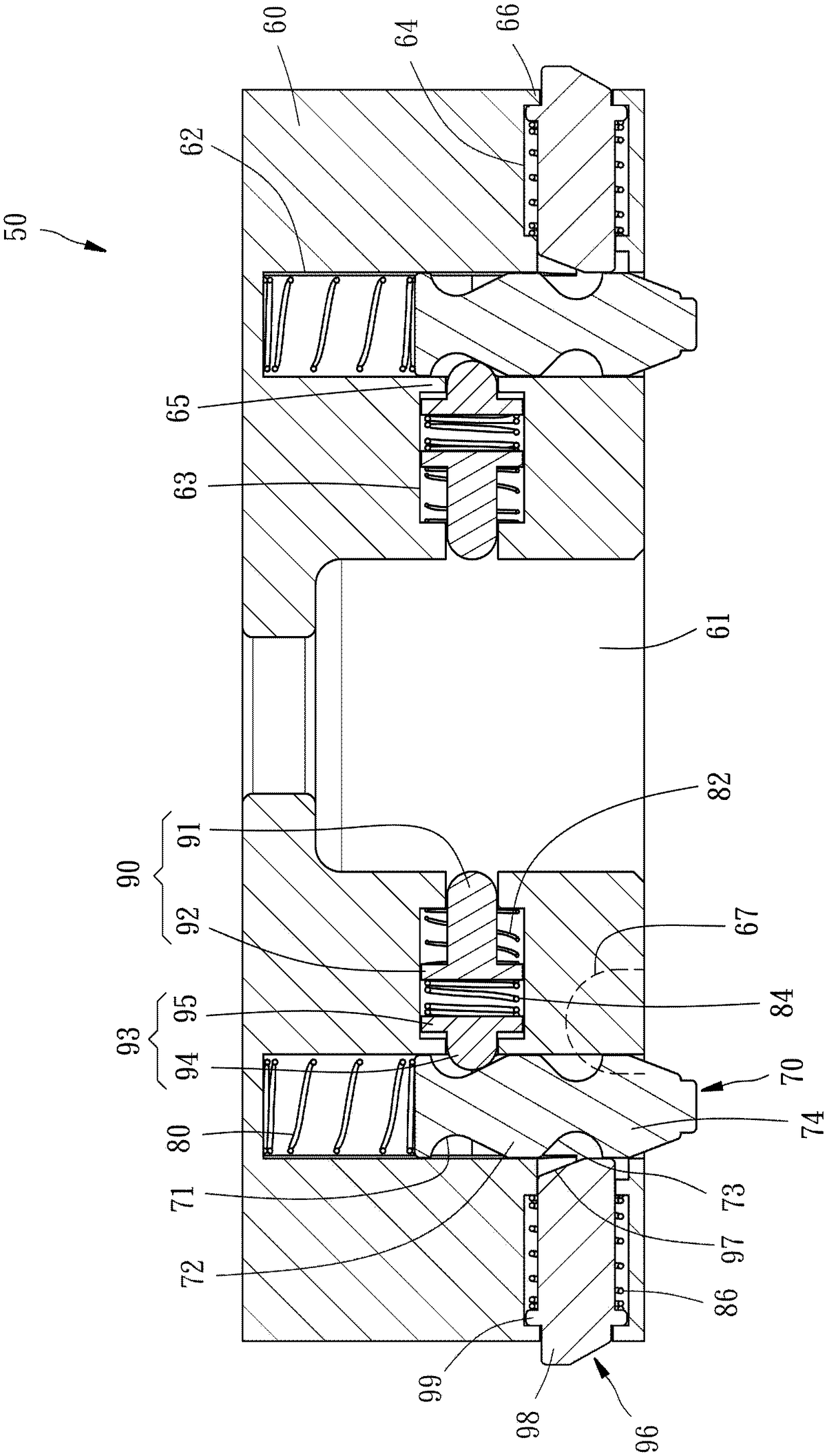

[0045] see figure 1 and figure 2 , the mechanical replacement device 10 of the first embodiment of the present invention includes a base 20 , a damper 30 , a first connection unit 40 , and a second connection unit 50 .

[0046] The base 20 has a bottom wall 21, a ring wall 22 above the bottom wall 21, and three support rods 23 connected between the bottom wall 21 and the ring wall 22, wherein the inner ring surface of the ring wall 22 has an inner flange24.

[0047] The damper 30 can choose to use a viscoelastic damper, a hydraulic damper or a vibration damper. In this embodiment, a viscoelastic damper 30 (Viscoelastic damper) is the best implementation, but not limited thereto. The damper 30 has an upper support plate 31 , a lower support plate 32 , and a plurality of viscoelastic damping elements 33 connected between the upper and lower support plates 31 , 32 . When assembled, the damper 30 is placed on the inner flange 24 of the ring wall 22 of the base 20 through the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com