A Pneumatic Yarn Threading Two-for-One Twisting Spindle for Large Packages

A technology of double-twisting spindles and large packages, which is applied in textile and papermaking directions, can solve problems such as the inability to meet the requirements of yarn tension and uniformity control, reduce quality defects, improve equipment operation rate, and tension uniformity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

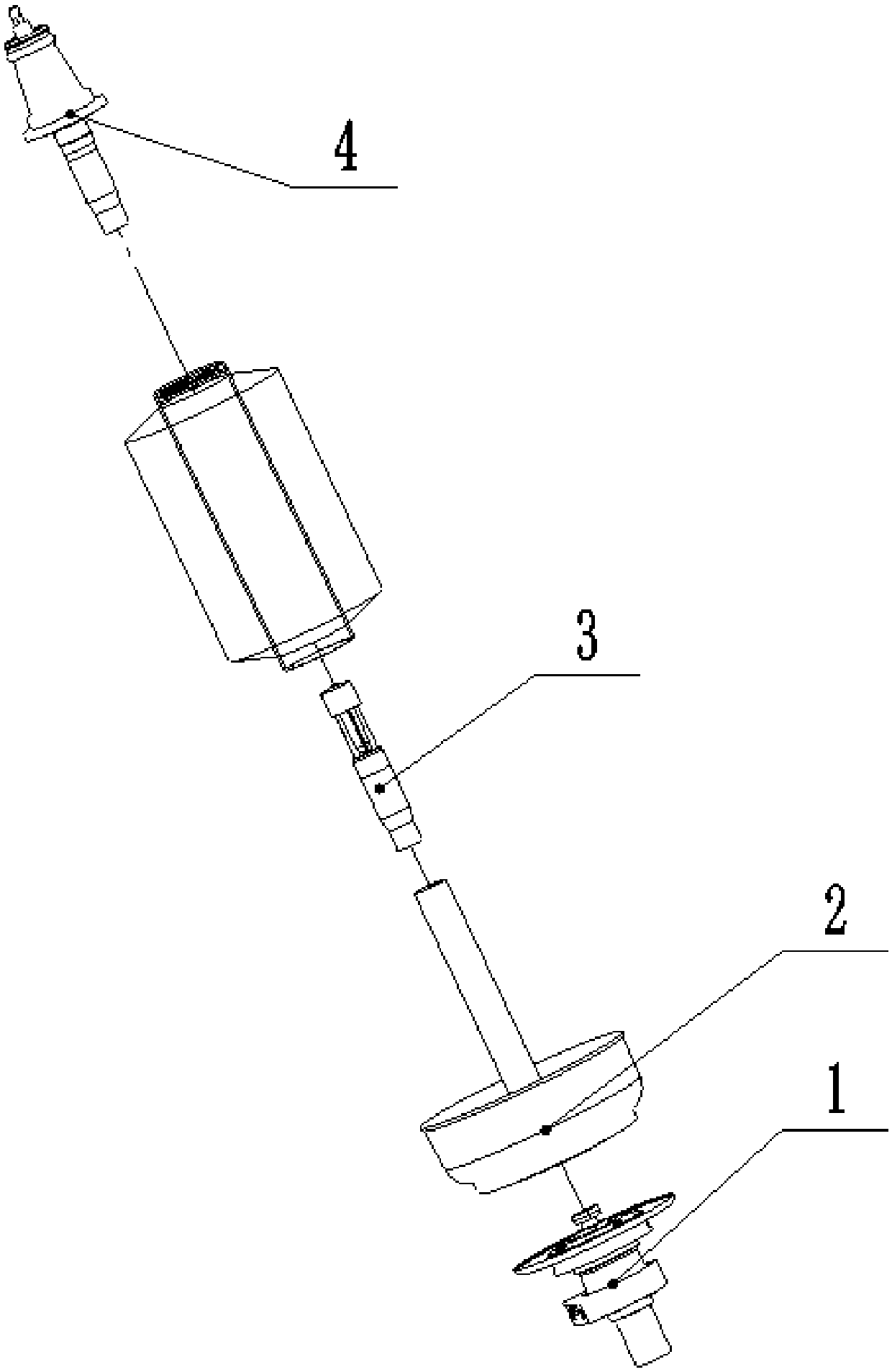

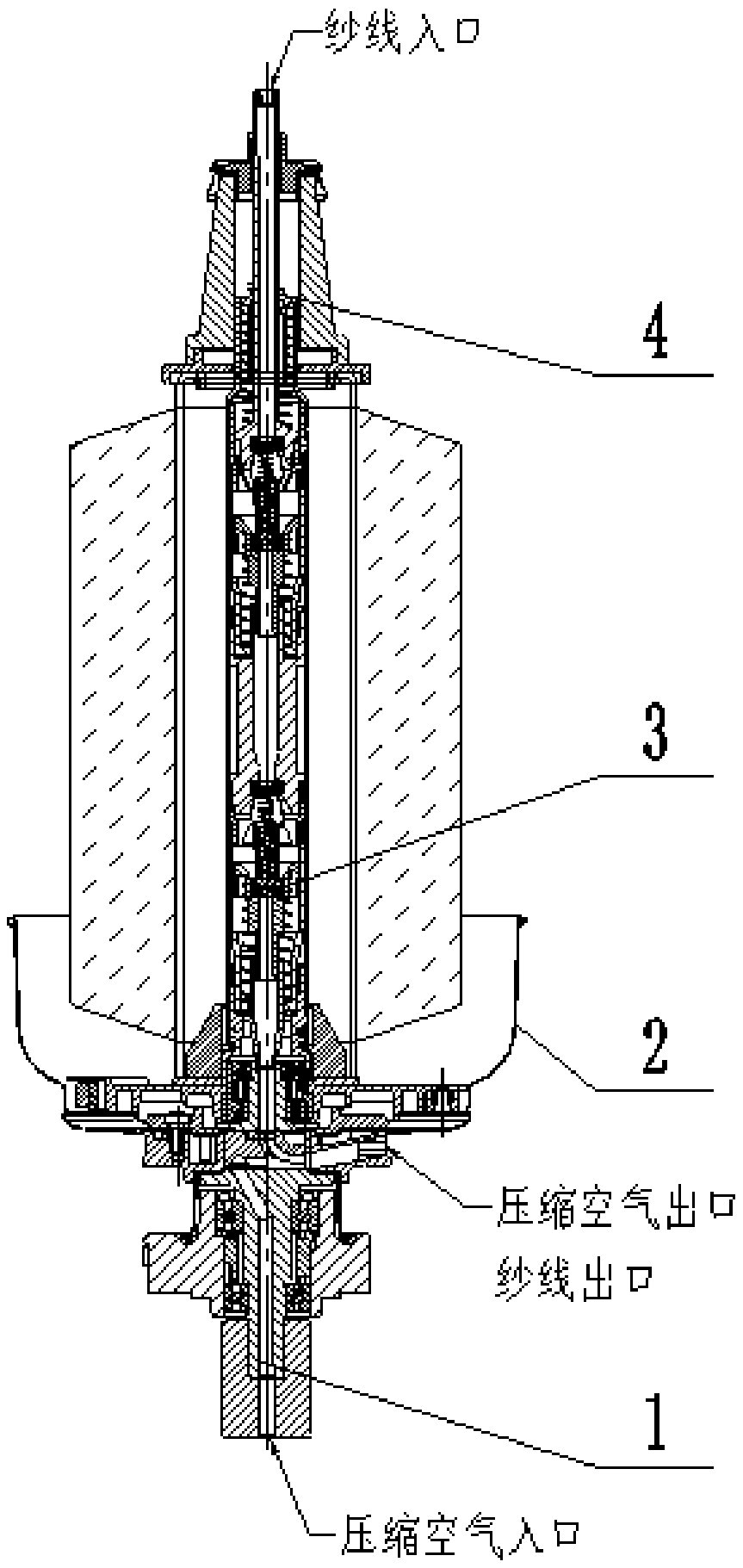

[0037] Such as figure 1 with figure 2 As shown, a large package pneumatic yarn threading two-for-one twisting spindle in this embodiment includes a rotor assembly 1, a yarn pot assembly 2, a tension tube assembly 3 and a lining spindle assembly 4, wherein:

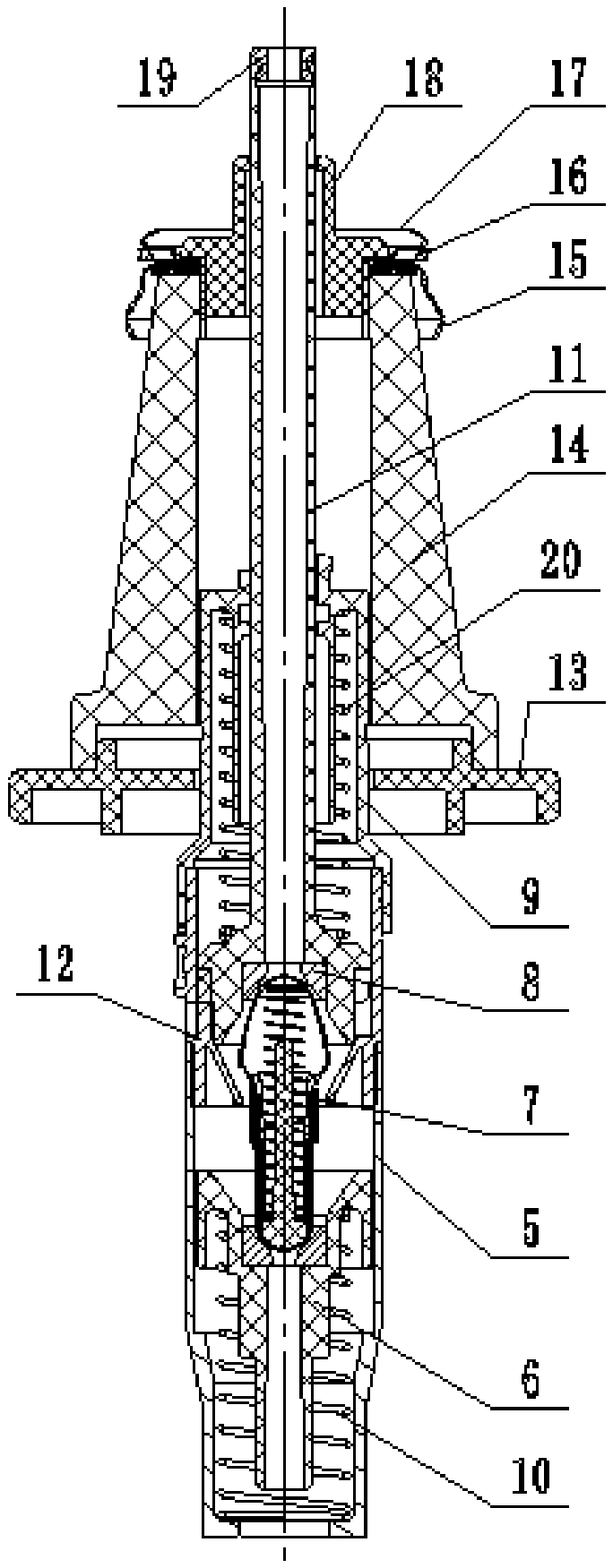

[0038] combine figure 2 , Image 6 As shown, the yarn pot assembly 2 includes a stationary disk 30 and a housing tube 28, the cylindrical housing tube 28 is arranged in the middle of the upper surface of the disc-shaped static disk 30 through a fixing seat 32, and the lower part of the housing tube 28 is provided There is a support tube 29, and the inside of the fixed seat 32 is provided with an annular boss, the seat tube 29 is provided with a buckle, and the receiving tube 28 is provided with a slot. When installing, the lower end of the receiving tube 28 is supported on the annular boss of the fixed seat 32 Above, the slot of the housing tube 28 is aligned with the buckle on the support tube 29, and the housing tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com