Double-valve pump core structure with pressure retaining and boosting functions

A valve and pump core technology, applied in the field of double-valve pump core structure, can solve the problems of lack of pressure maintaining, boosting and instantaneous release of internal pressure, unsatisfactory spray effect, low pass rate and use rate, etc., to achieve fog Good chemical effect, good sealing, and the effect of improving the pass rate and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

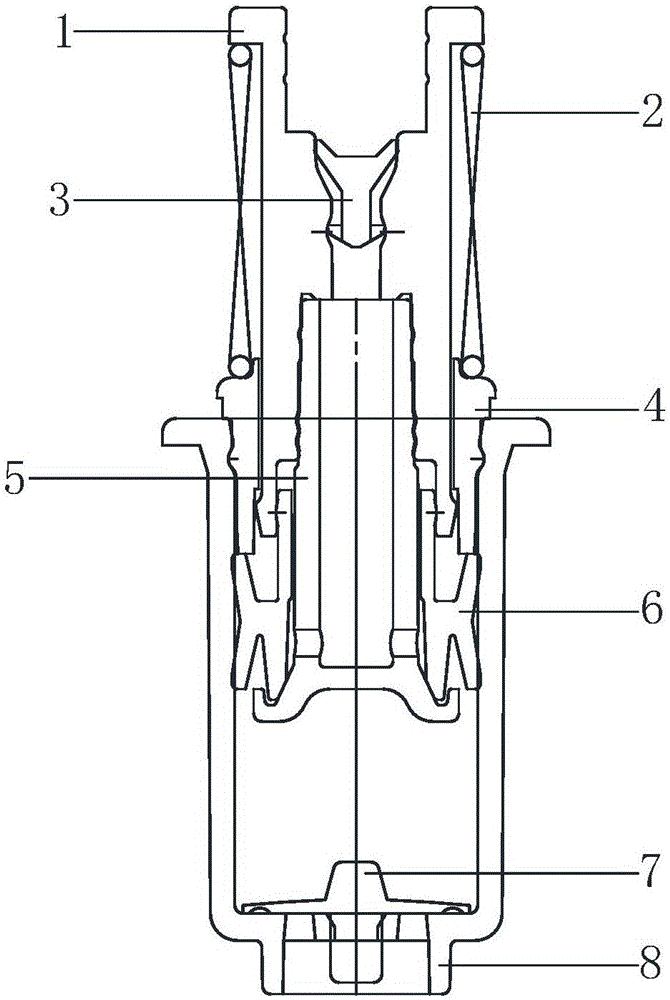

[0009] see figure 1 , a double-valve pump core structure with pressure maintaining and boosting functions, including a body 8, a large valve 7 is provided on the bottom inlet of the body 8, and a collar 4 is fixedly connected to the top of the body 8, A main column 1 is inserted in the collar piece 4, and an auxiliary column 5 affixed thereto is arranged below the main column 1, and a piston 6 is fixed between the main column 1 and the auxiliary column 5, The piston 6 is arranged on the outside of the auxiliary column 5 and fixedly connected to the lower end of the main column 1, the piston 6 is installed in the inner cavity of the body 8, and the two form a sliding and sealed connection. A spring 2 is clamped between the collar piece 4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com