Two-half type engineering tensioning system with screw teeth

A tensioning and screw thread technology, which is applied in bridge form, processing of building materials, erection/assembly of bridges, etc., can solve the problems of inability to tension construction, unable to provide reaction force points, etc., to improve construction quality, facilitate reuse, The effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

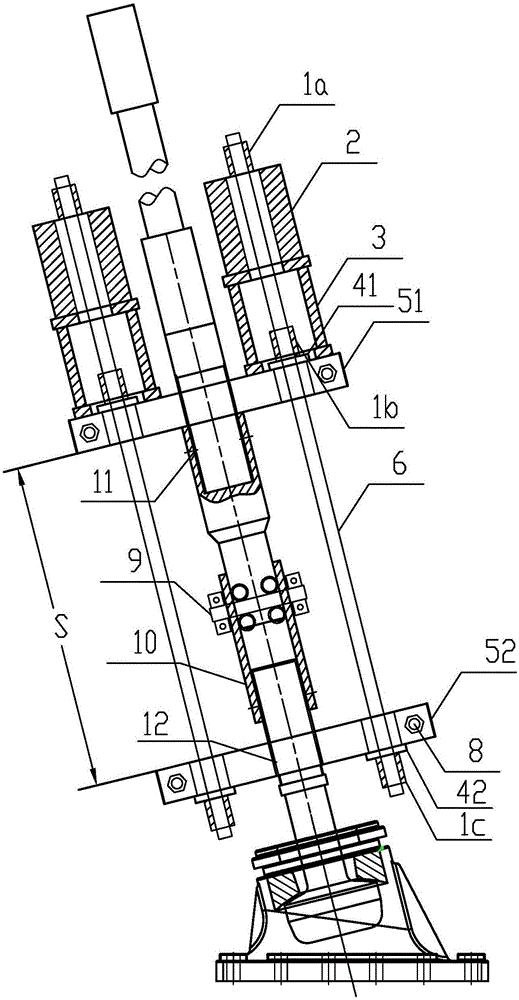

[0061] A two-half type screw threaded engineering tensioning system in which the anchor holes on the upper tension pole beam 51 and the lower tension pole beam 52 have threads.

[0062] Such as figure 1 As shown, the two-half-type engineering tensioning system with threads includes an upper part reaction device, a lower part reaction device, a tension rod 6 connecting the upper part reaction device and the lower part reaction device, and a tension rod 6 installed in the adjustment The hoop 9 on the sleeve 10, the upper part of the reaction device includes the upper tension nut 1a, the jack 2, the tension support foot 3, the tension temporary anchor nut 1b, the temporary anchor pad I41 and the upper tension pole beam 51. The lower part of the reaction device includes the lower tension pole beam 52, the lower tension nut 1c and the temporary anchoring backing plate II 42;

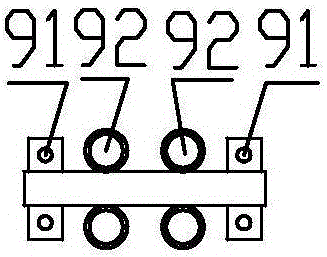

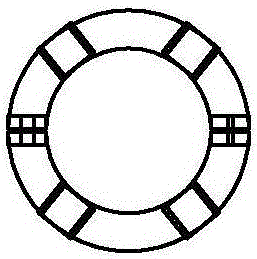

[0063] Such as Figure 4-1~Figure 4-2 As shown, the anchor holes on the upper tension pole beam 51 and the lowe...

Embodiment 2

[0066] The anchor hole on the upper tension pole beam 51 and the lower tension pole beam 52 is a two-half type engineering tensioning system with threads without threads.

[0067] Such as figure 1 As shown, the two-half-type engineering tensioning system with threads includes an upper part reaction device, a lower part reaction device, a tension rod 6 connecting the upper part reaction device and the lower part reaction device, and a tension rod 6 installed in the adjustment The hoop 9 on the sleeve 10, the upper part of the reaction device includes the upper tension nut 1a, the jack 2, the tension support foot 3, the tension temporary anchor nut 1b, the temporary anchor pad I41 and the upper tension pole beam 51. The lower part of the reaction device includes the lower tension pole beam 52, the lower tension nut 1c and the temporary anchoring backing plate II 42;

[0068] Such as Figure 5-1~Figure 5-2 As shown, the anchor holes on the upper tension pole beam 51 and the lower tens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com