oil well pump

A technology of oil well pump and pump barrel, applied in the direction of pump, pump components, variable capacity pump components, etc., can solve the problem of unreasonable structure of ceramic plunger and metal matrix, and meet the precision requirements, no stuck pump, fit clearance Stable and precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

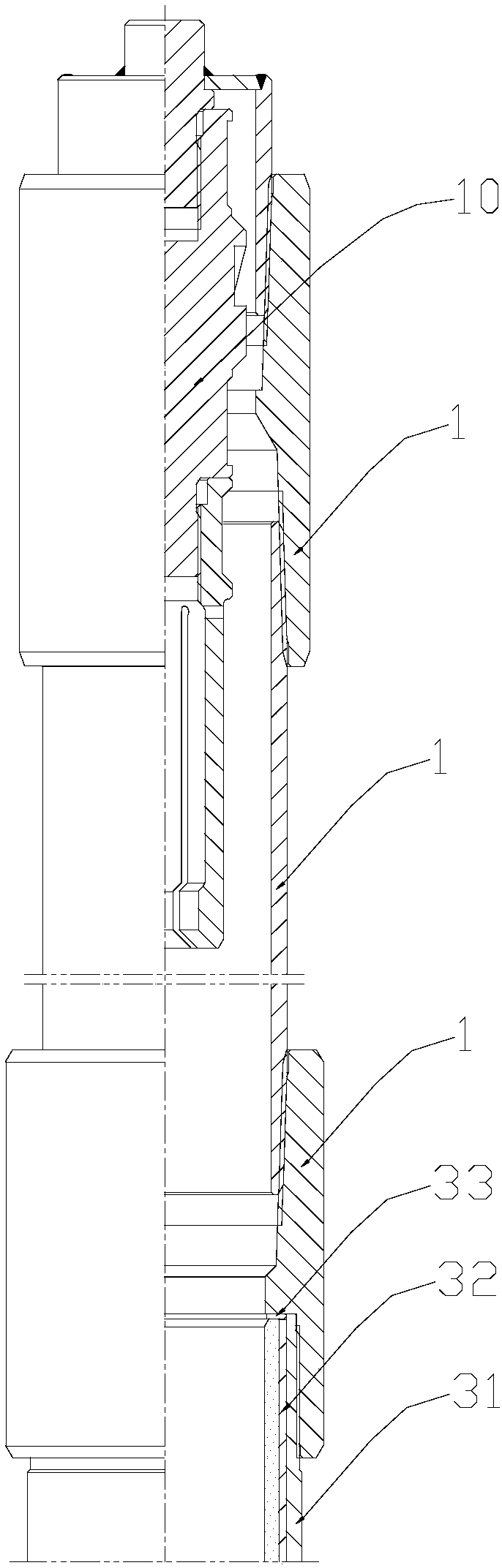

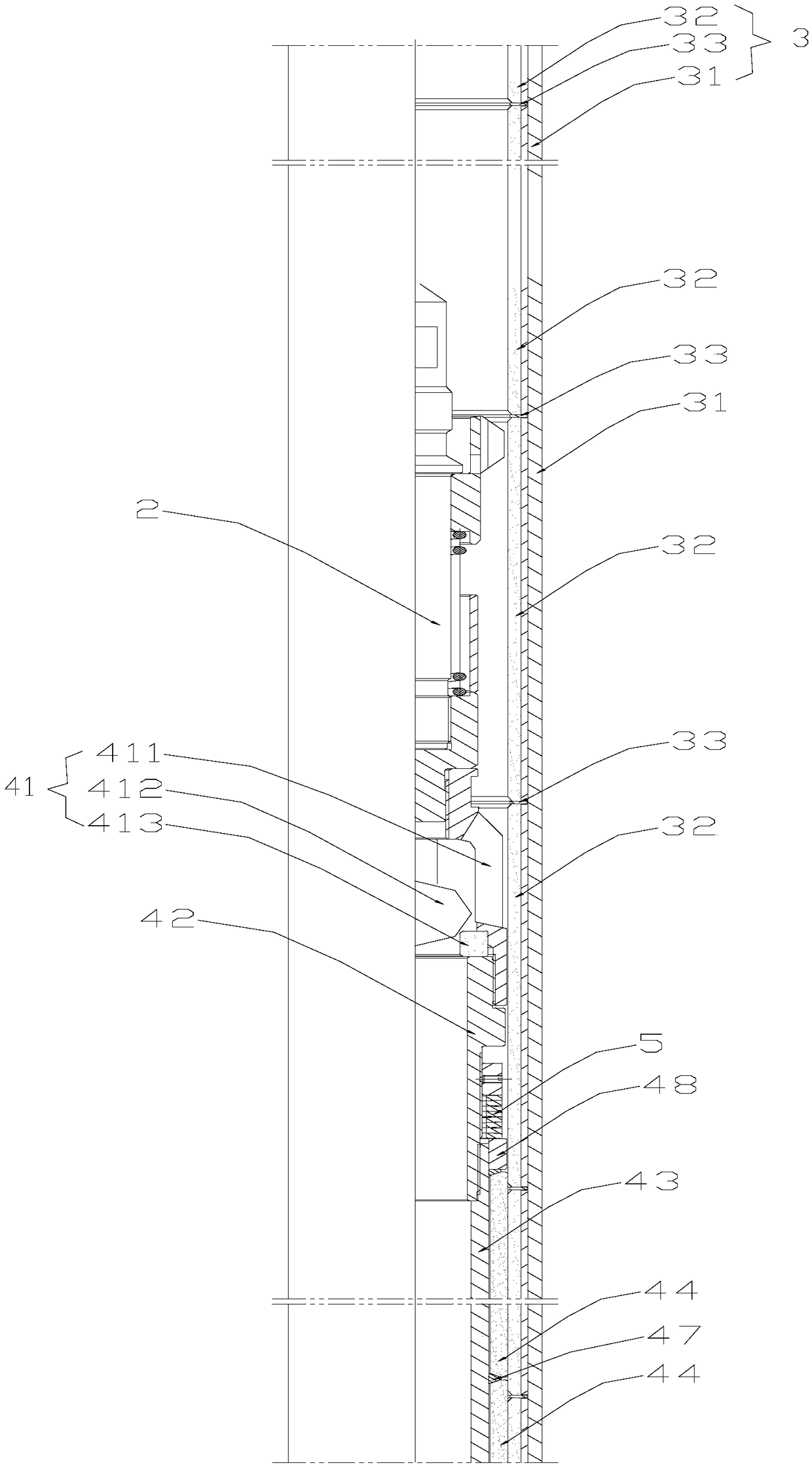

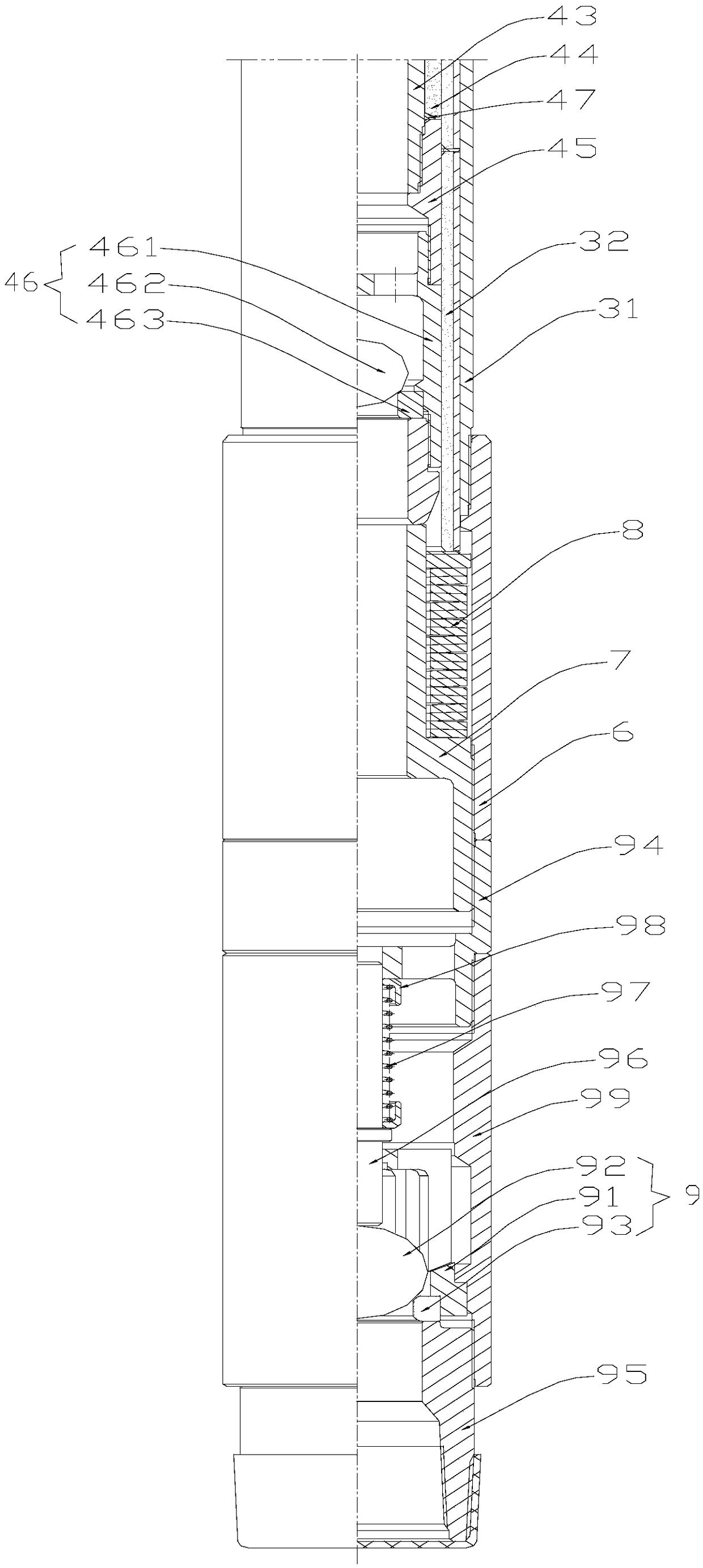

[0040] The details of the present invention can be understood more clearly with reference to the accompanying drawings and the description of specific embodiments of the present invention. However, the specific embodiments of the present invention described here are only for the purpose of explaining the present invention, and should not be construed as limiting the present invention in any way. Under the teaching of the present invention, the skilled person can conceive any possible modification based on the present invention, and these should be regarded as belonging to the scope of the present invention.

[0041] In order to solve the problem of unreasonable structure between the ceramic plunger 44 and the metal matrix, the lifting technology of the all-ceramic oil well pump was finally formed to meet the lifting technical requirements of steam flooding, SAGD and other heavy oil thermal recovery wells, and was used for SAGD, etc. The development of heavy oil provides reliab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com