Elevating insulator cross arm for uninterrupted operation of distribution network and operation method of using elevating insulator cross arm

An insulated cross-arm, lift-type technology, applied in the direction of overhead lines/cable equipment, etc., to achieve the effect of reducing the number and time of power outages, convenient operation methods, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

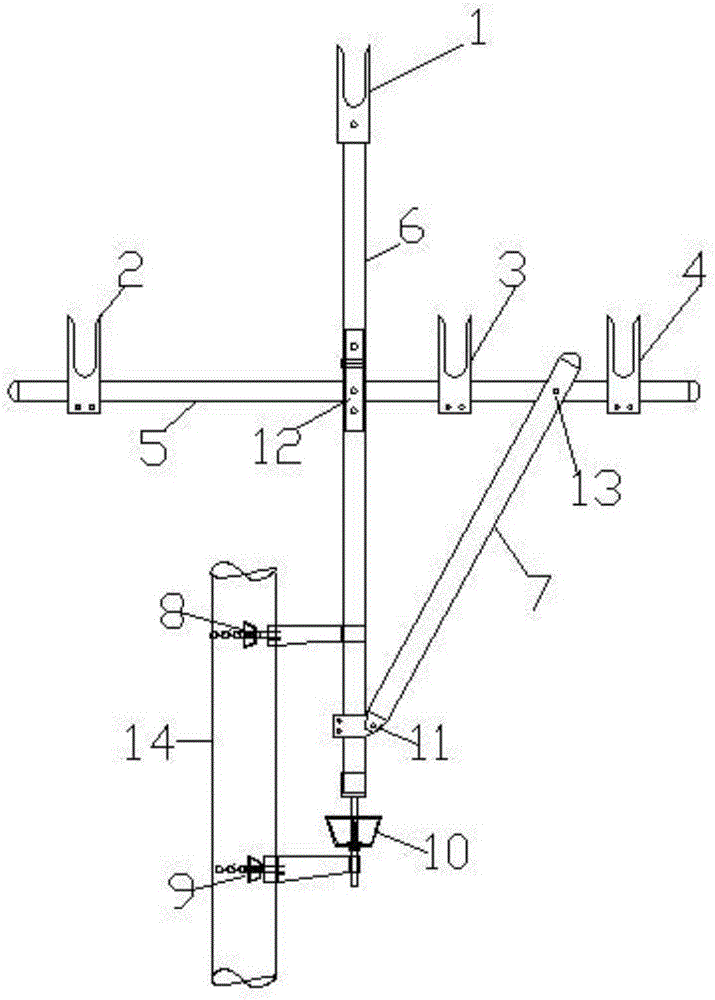

[0025] The present invention is described in further detail below in conjunction with accompanying drawing:

[0026] see figure 1 , the present invention uses a lift-type insulating cross arm for non-stop operation of the distribution network, including a first epoxy resin tube 5, a second epoxy resin tube 12 and a third epoxy resin tube 7; the second epoxy resin tube 12 is fixed on the second epoxy resin tube The middle part of an epoxy resin tube 5, the two ends of the third epoxy resin tube 7 are respectively fixedly connected with the first epoxy resin tube 5 and the second epoxy resin tube 12 to form a triangular structure; the third epoxy resin tube 7 The lower end is fixed on the second epoxy resin tube 12 by the first bolt 11, and the upper end is fixed on the first epoxy resin tube 5 by the second bolt 13. The fourth epoxy resin tube 6 is inserted into the second epoxy resin tube 12 and fixed with bolts, and the fourth epoxy resin tube 6 is moved by plugging and unpl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com