Packaging box surface treatment local uv machine transformation structure

A technology of surface treatment and structural transformation, applied in printing presses, general parts of printing machinery, printing, etc., can solve the problem of large color box size and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

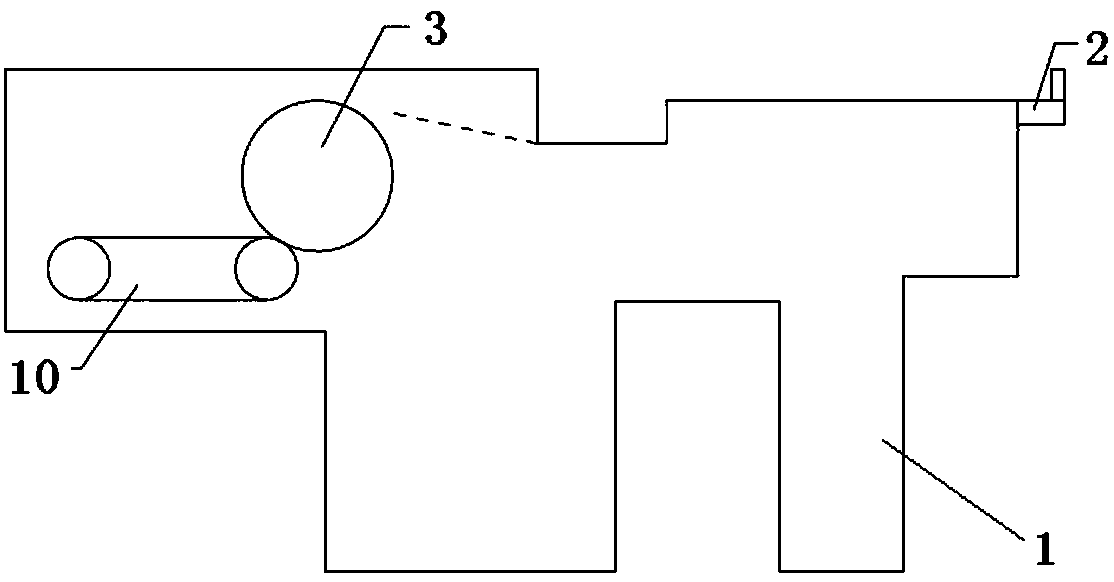

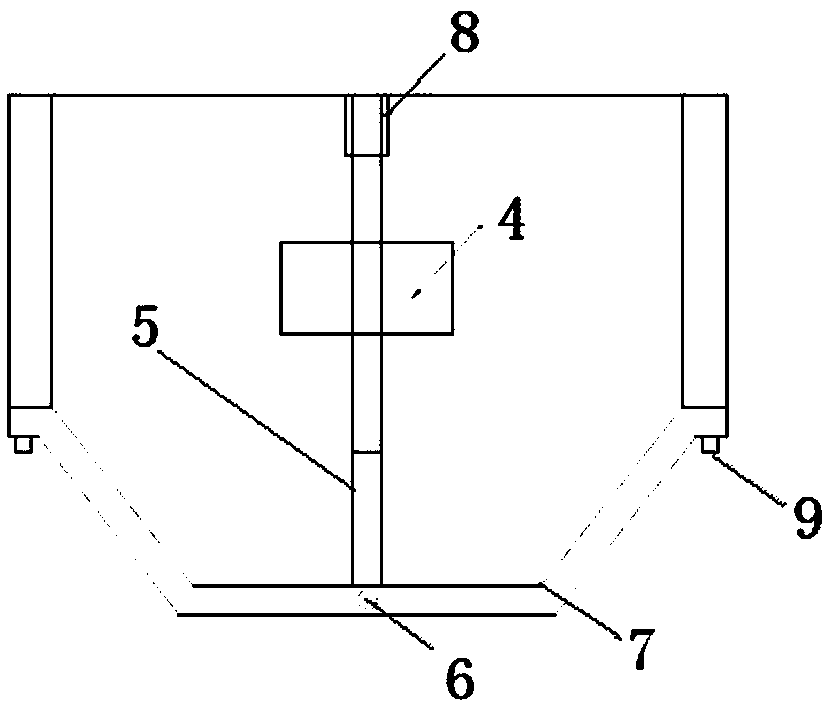

[0011] figure 1 It shows an embodiment of the modified structure of a local UV machine for packaging box surface treatment in the present invention, including a machine platform 1, on which a feeder 2 for continuous paper feeding is installed, and a printing cylinder 3 for printing, And the suction belt 10 for output, the feeder 1 is composed of a paper-absorbing feeder head 4 installed on the top of one side of the machine table 1, an adjusting screw rod 5 and a feeder head regulator 6, and the paper-absorbing feeder The head 4 is installed on the adjusting screw rod 5, and one end of the adjusting screw rod 5 is fixed on the cross bar 7 connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com