Manufacturing method of air-permeable metal shell body structure for reducing resistance of fluid to moving object and application

A technology of moving objects and gas-permeable metals, applied in the field of reducing fluid resistance, can solve the problems of difficult processing of porous silicon material plates, inability of the bottom of the ship, and obstacles to practical applications, etc., to achieve improved safety and reliability, shortened travel time, and easy pore size The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

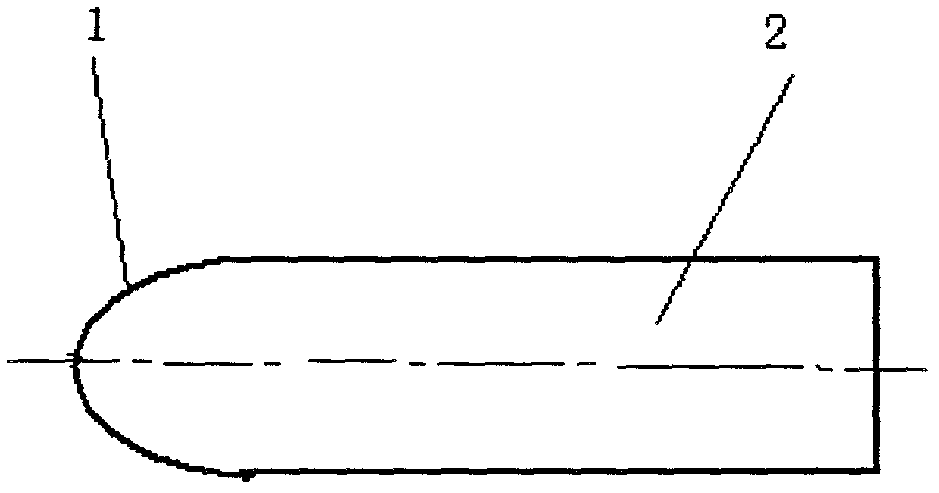

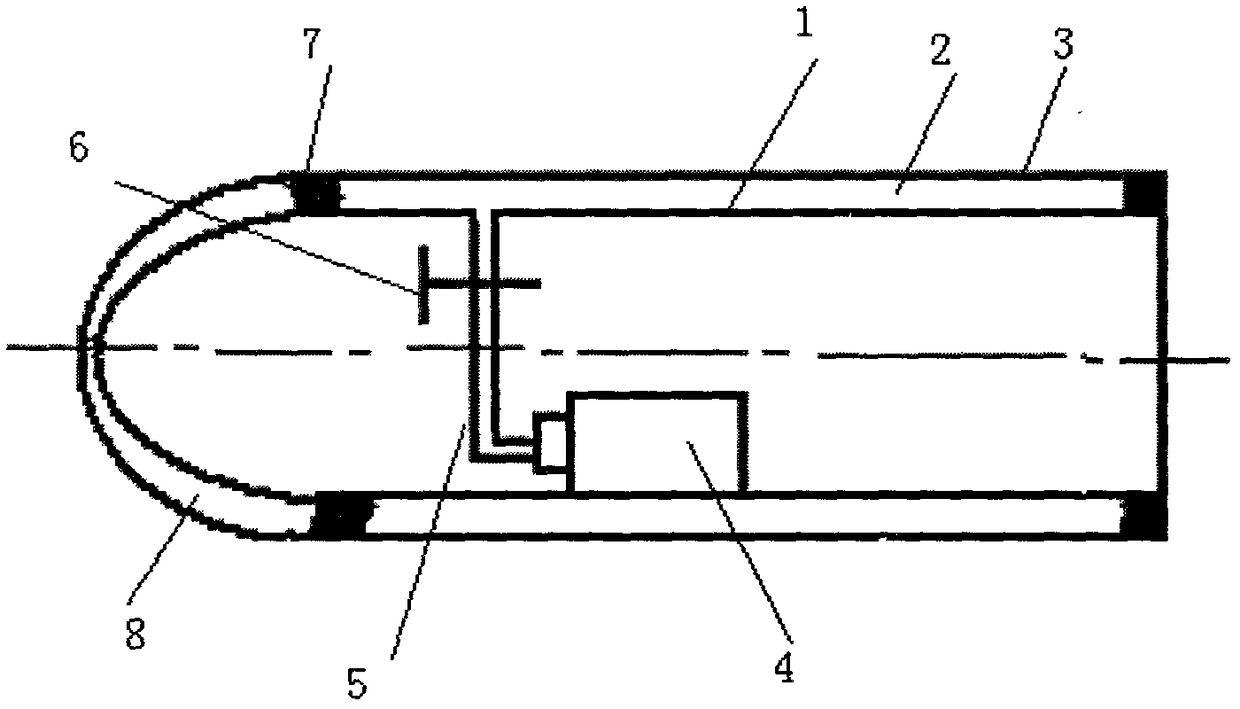

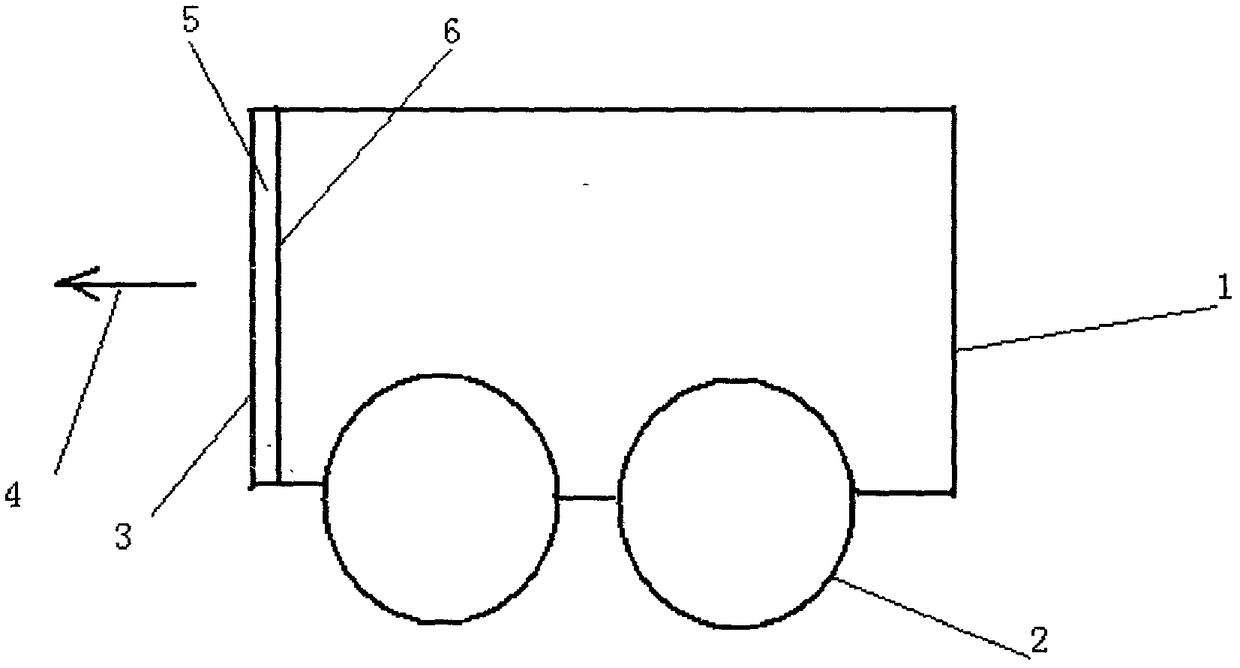

[0030] The technical solution provided by the present invention is: a method for manufacturing a breathable metal shell structure that reduces the resistance of fluid to moving objects. First, weave metal fiber filaments to form a braided body slab, then sinter, and then press the fiber through plastic processing. Silk sintered slab, compressing the pore size of the fiber sintered blank, reducing the porosity of the material, improving the mechanical properties of the material, while maintaining the connectivity of the material pores, obtaining a breathable fiber metal plate; and then manufacturing the breathable metal plate through plastic pressure processing The shape and size of the shell of the moving object are obtained to obtain a breathable shell structure, so that one side of the multi-microporous breathable metal plate material forms the outer surface of the moving object shell, and the other side forms the inner surface of the moving object shell, and constitutes a clo...

Embodiment 2

[0033] The difference from Example 1 is that the present example adopts 200 20 steel wires with a diameter of 50 microns as a bunch, and the braiding machine carries out multi-bundle braiding, braiding a braided board body with a length of 2000 millimeters, a width of 300 millimeters and a thickness of 10 millimeters, and then Sinter at a temperature of 1250 degrees Celsius for 2 hours to achieve metallurgical bonding between the wires to obtain a sintered slab body, and then place the sintered woven sheet material body between the rolls of a plate rolling machine at room temperature for rolling processing to compress the fibers The pore size of the sintered billet reduces the porosity of the material, improves the mechanical properties of the material, and at the same time maintains the connectivity of the material pores to obtain a 5 mm thick breathable fiber metal plate, and then process the breathable fiber metal plate into the shell shape of the moving object and size.

Embodiment 3

[0035] The difference from Example 1 is that in this embodiment, a layer of stainless steel powder is uniformly distributed on the fiber filament sintered slab, the stainless steel powder is 100 microns, and then the stainless steel powder is rolled on the fiber filament sintered slab, and then the stainless steel is sintered The powder layer combines the stainless steel powder on the fiber filament sintered base plate and keeps the pores between the powder particles connected to obtain a breathable metal plate whose pore size is distributed along the thickness step change. The pore size change distribution of the multi-microporous breathable material is step change. The largest pore size on the fiber surface is 100 microns, the smallest pore size on the powder surface is 5 microns, the thickness of the air-permeable fiber layer is 5 mm, and the thickness of the air-permeable powder layer is 0.5 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com