Process For Manufacturing Coating Gun And Coating Gun

A manufacturing method and coating technology, applied in the direction of spraying device, spraying device, liquid spraying device, etc., can solve problems such as excessive consumption of compressed air, poor geometry of the action area, and reduced effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

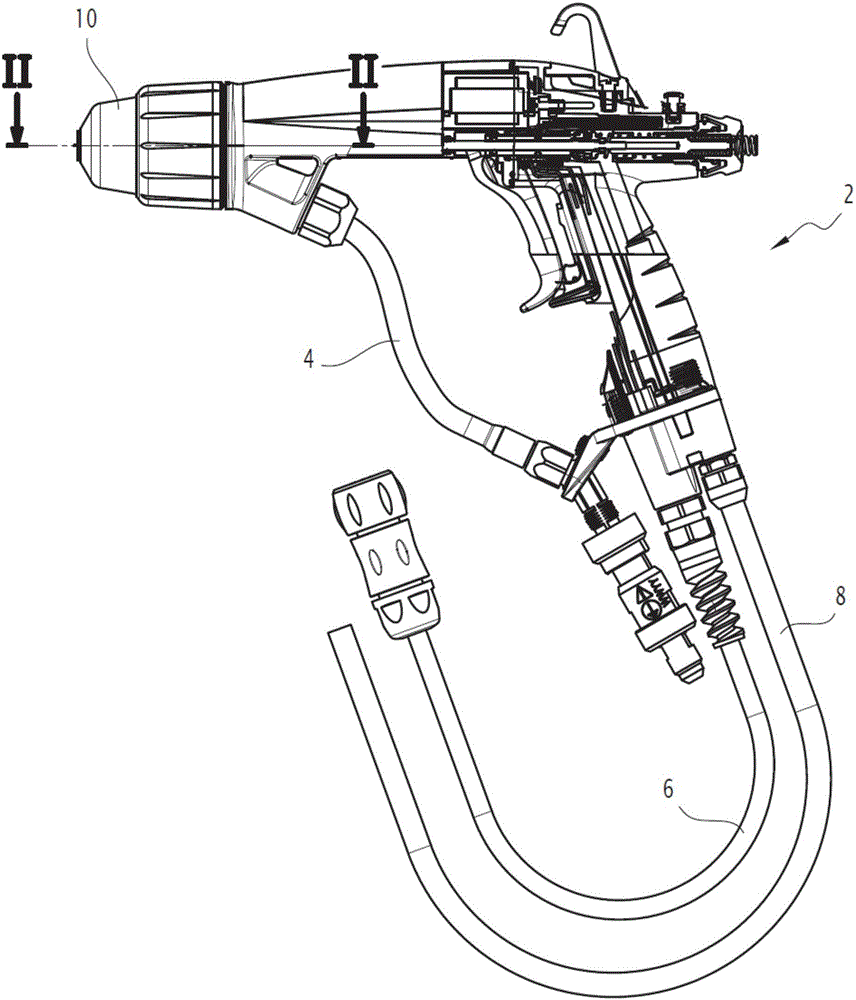

[0034] Figure 1 ~ Figure 3 Shown is an applicator gun 2 for applying a paint product. In this example, the paint product is paint in powder or liquid form. Alternatively, it may also be a varnish, a solvent, an ink or a lubricant (for example as oil).

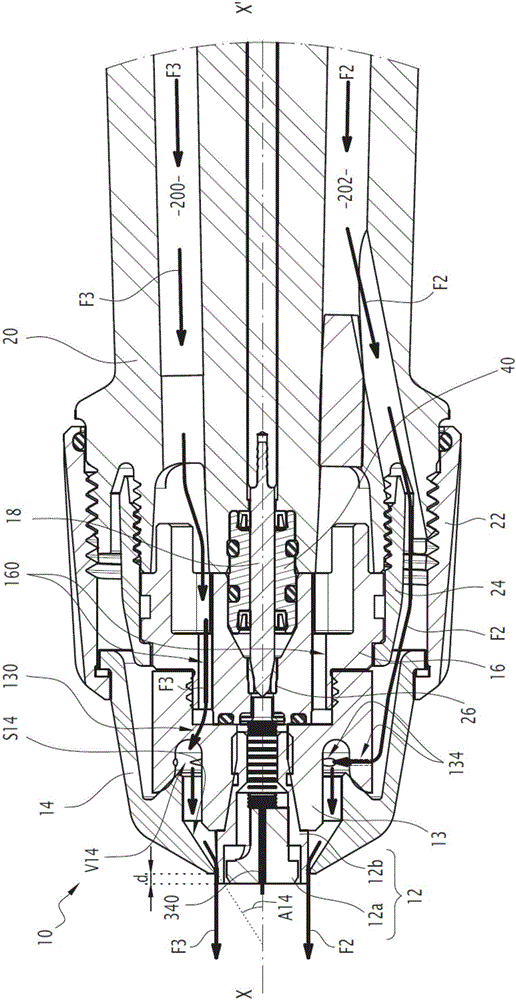

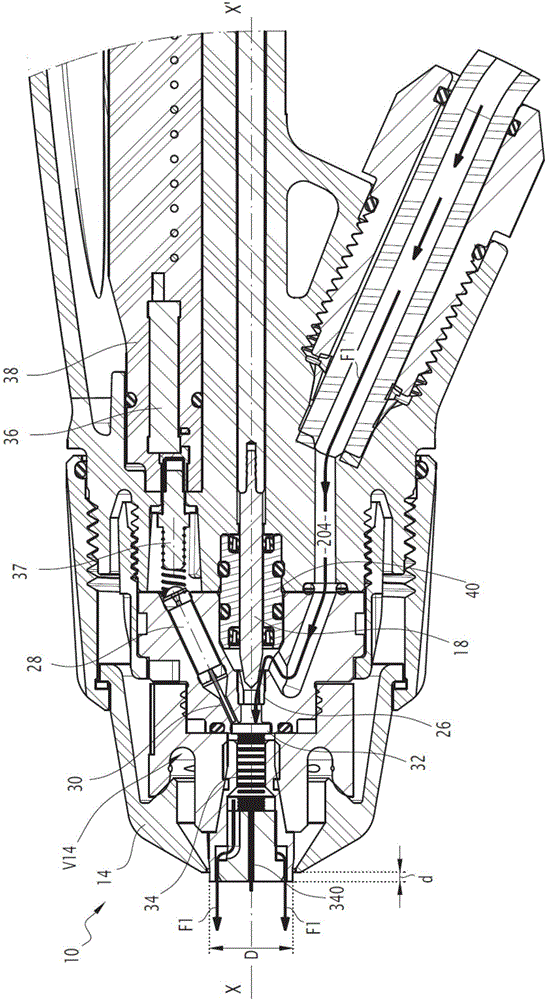

[0035] The applicator gun 2 comprises a product supply tube 4, a compressed air supply tube 8, and a power cord 6 for electrostatically charging the product. The coating gun 2 also includes a spray head 10, see the cross-sectional view for details figure 2 with image 3 .

[0036] Such as figure 2 As shown, spray head 10 comprises injectors 12 for spraying a stream of product along spray axis XX'. The injector 12 is formed by two coaxial parts 12a and 12b forming an annular product injection channel between them. Accordingly, the injector 12 is arranged with a circular active area. Depending on the pressure of the product flow, the active area may also be in the shape of a disc or a ring. The injector 12 is thus a "...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com