A method for testing the rheological properties of solid-liquid two-phase regions of alloys using a high-temperature creep tester

A technology of high-temperature creep and rheology, which is applied in flow characteristics, indirect flow characteristics measurement, instruments, etc., can solve the problems that the displacement is larger than the real value and the calculation method is rough, so as to achieve accurate creep displacement and simple calculation Convenient, accurate, rheologically accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

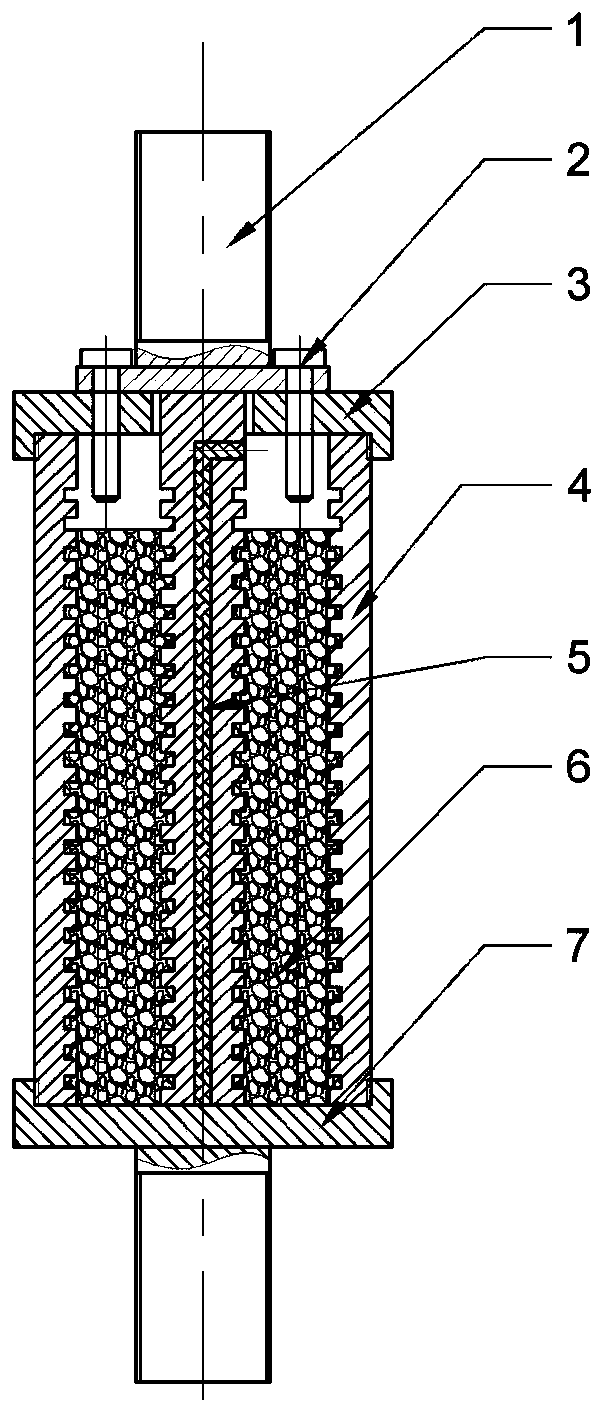

[0019] Specific implementation mode one: as figure 1 As shown, a tensile shear rheometer in this embodiment is composed of a tie rod 1, a positioning pin 2, an upper end cover 3, a crucible 4, a high alumina fiber 5 and a lower end cover 7; the upper port of the crucible 4 is provided with an upper end Cover 3, the lower port of the crucible 4 is provided with a lower end cover 7; the upper part of the pull rod 1 is provided with a boss and two holes are punched on the boss, and the upper end cover 3 is provided with two holes on the boss. The hole matched with the hole, and the positioning pin 2 forms a clearance fit. The center of the upper end cover 3 also has a through hole. The lower part of the pull rod 1 passes through the through hole of the upper end cover 3 and is arranged in the crucible 4 and connected with the lower end. The upper surface of the cover 7 contacts, and the boss on the pull rod 1 is stuck on the upper surface of the upper end cover 3; the lower end o...

specific Embodiment approach 2

[0025] Embodiment 2: This embodiment differs from Embodiment 1 in that: the groove is a right-angle groove, an oblique groove or a screw thread. Others are the same as in the first embodiment.

[0026] In this embodiment, grooves are provided on the tie rod 1 to prevent the solid-liquid mixed melt from sliding relative to the molten metal during deformation.

specific Embodiment approach 3

[0027] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the pull rod 1 is a column structure. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com