Blow molding plate sawing and fixing dual-purpose device

A sawing and dual-purpose technology, applied in hacksaw, step-down saw, metal processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

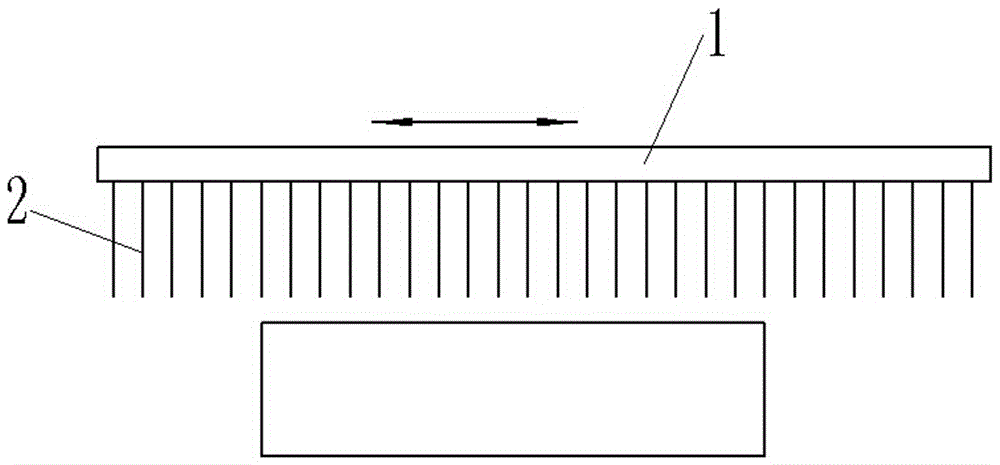

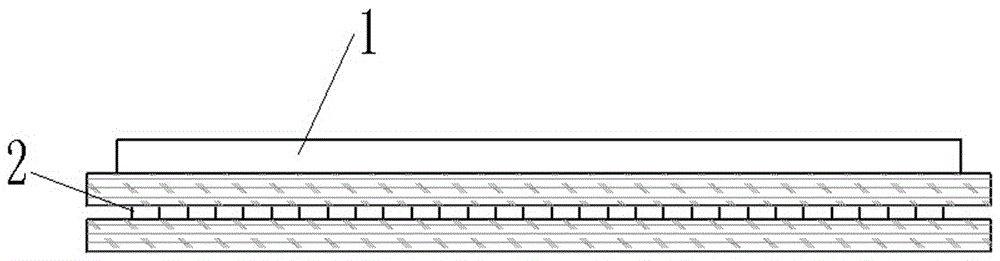

[0011] figure 1 , 2 Middle: Fixing bar 1, scraping needle 2.

[0012] Blow-molded board sawing and fixing dual-purpose device, the device includes a fixing strip 1 and a scraping needle 2, the scraping needle 2 is fixedly connected to the fixing strip 1, the scraping needle 2 is perpendicular to the fixing strip 1, The scraping needles 2 are arranged in a linear array, and the scraping needles 2 are easy to bend.

[0013] The distribution density of the scraping needles 2 is 20-30 per decimeter. The fixing strip 1 is a polished and chamfered square strip.

[0014] Such as figure 1 Shown is a schematic diagram of the implementation of sawing of the blow-molded board sawing and fixing dual-purpose device of the present invention. Pull left and right in the direction of the arrow in the illustration to cut the board saw. Realize the sawing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com