Forest cutting griping-saw operation device

A working device, forest technology, applied in forestry, agriculture, application and other directions, can solve the problem of not having both sawing and cutting trees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

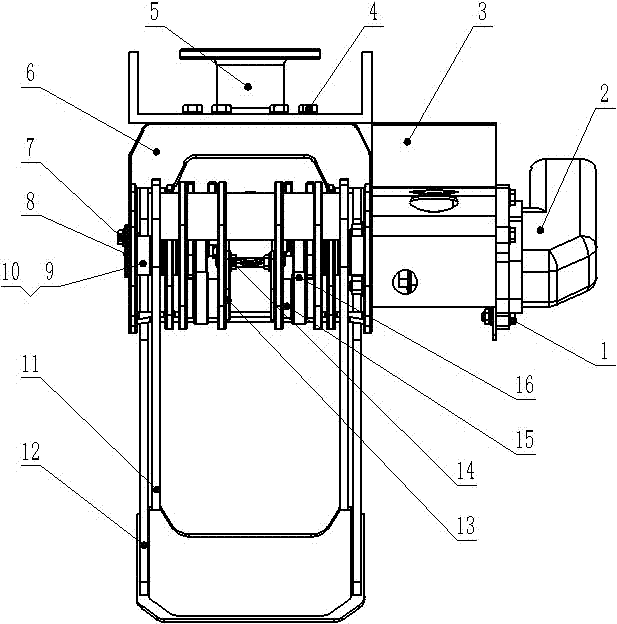

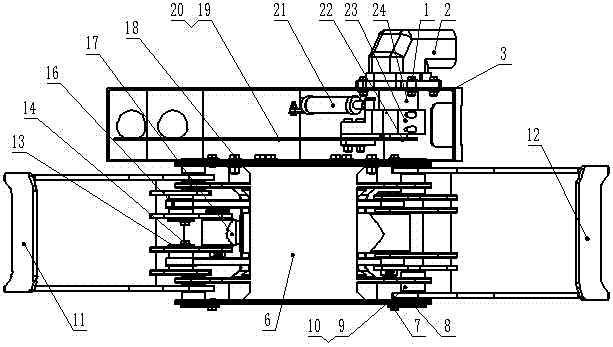

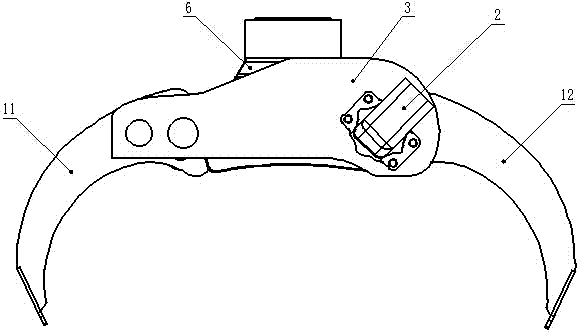

[0017] The implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings:

[0018] The forest felling sawing operation device of the present invention includes two parts, a grab and a chain saw, which are connected by six sets of bolts 18, which also facilitates the installation and disassembly of the chain saw on the grab. The gripper mainly includes a gripper main body 6 , grippers 11 and 12 , a gripper auxiliary plate 16 and a gripper hydraulic cylinder 17 . The chain saw mainly includes a chain saw housing 3 , a hydraulic motor 24 , a fixed plate 23 , a sprocket 22 , a saw chain 20 , a guide plate 19 and a chain saw hydraulic cylinder 21 .

[0019] The gripper main body 6 of the gripper is connected to the connecting frame 5 through six sets of bolts 4, and the connecting frame 5 can be connected to the small arm of the harvesting equipment.

[0020] The grippers 11, 12 of the gripper are connected to the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com