fuel injector

A fuel injector and injector technology, which can be applied to fuel injection devices, special fuel injection devices, charging systems, etc., can solve the problems of cost-effective manufacturing and achieve the effect of economical manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

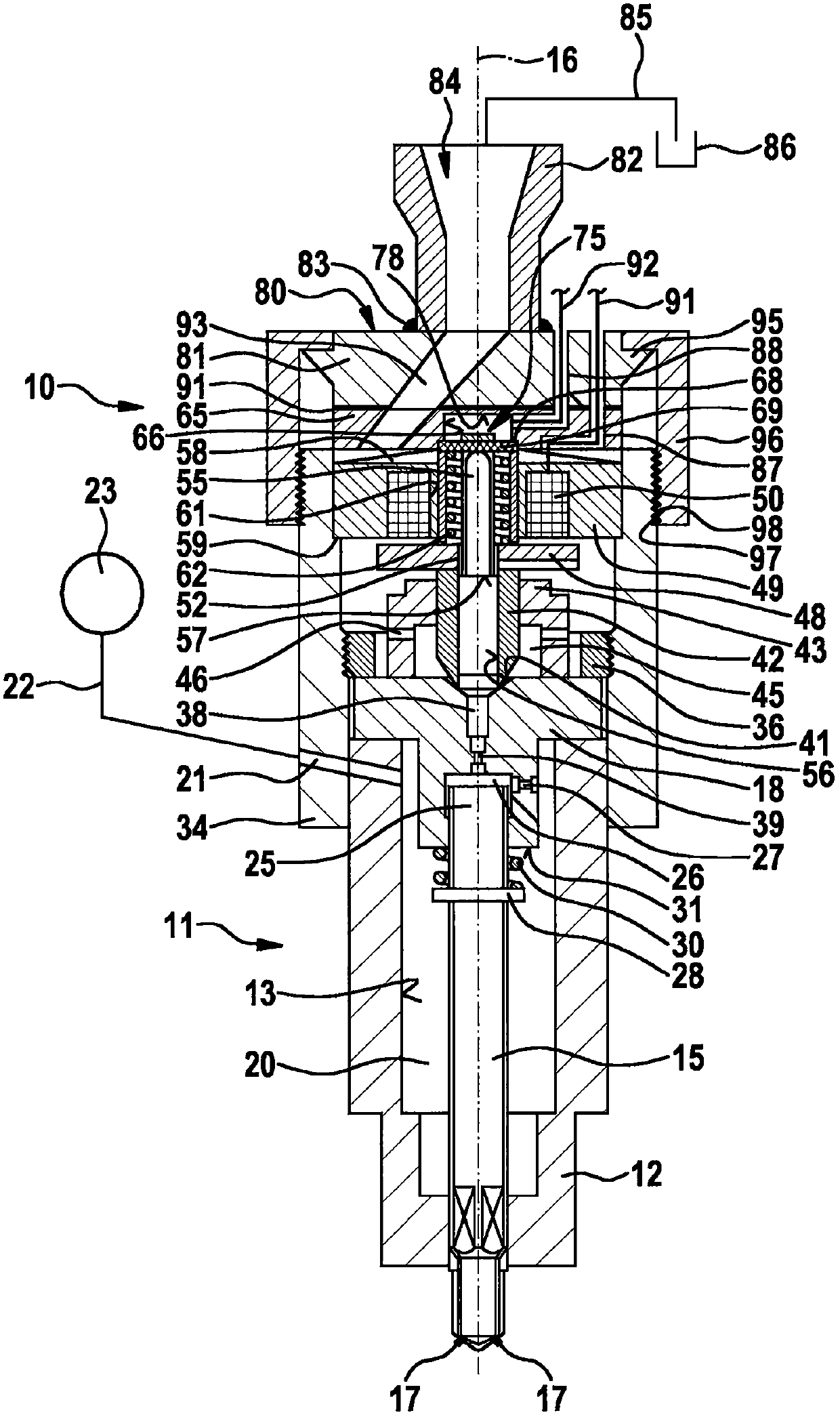

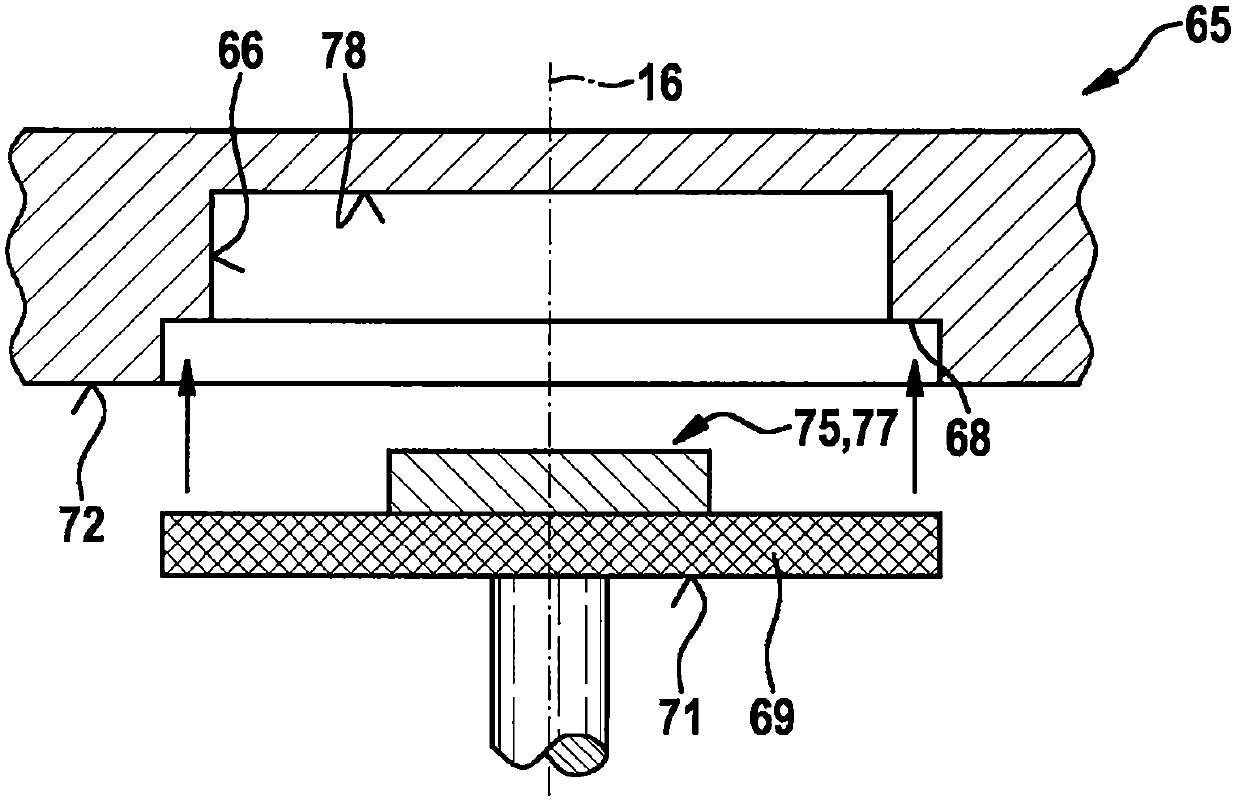

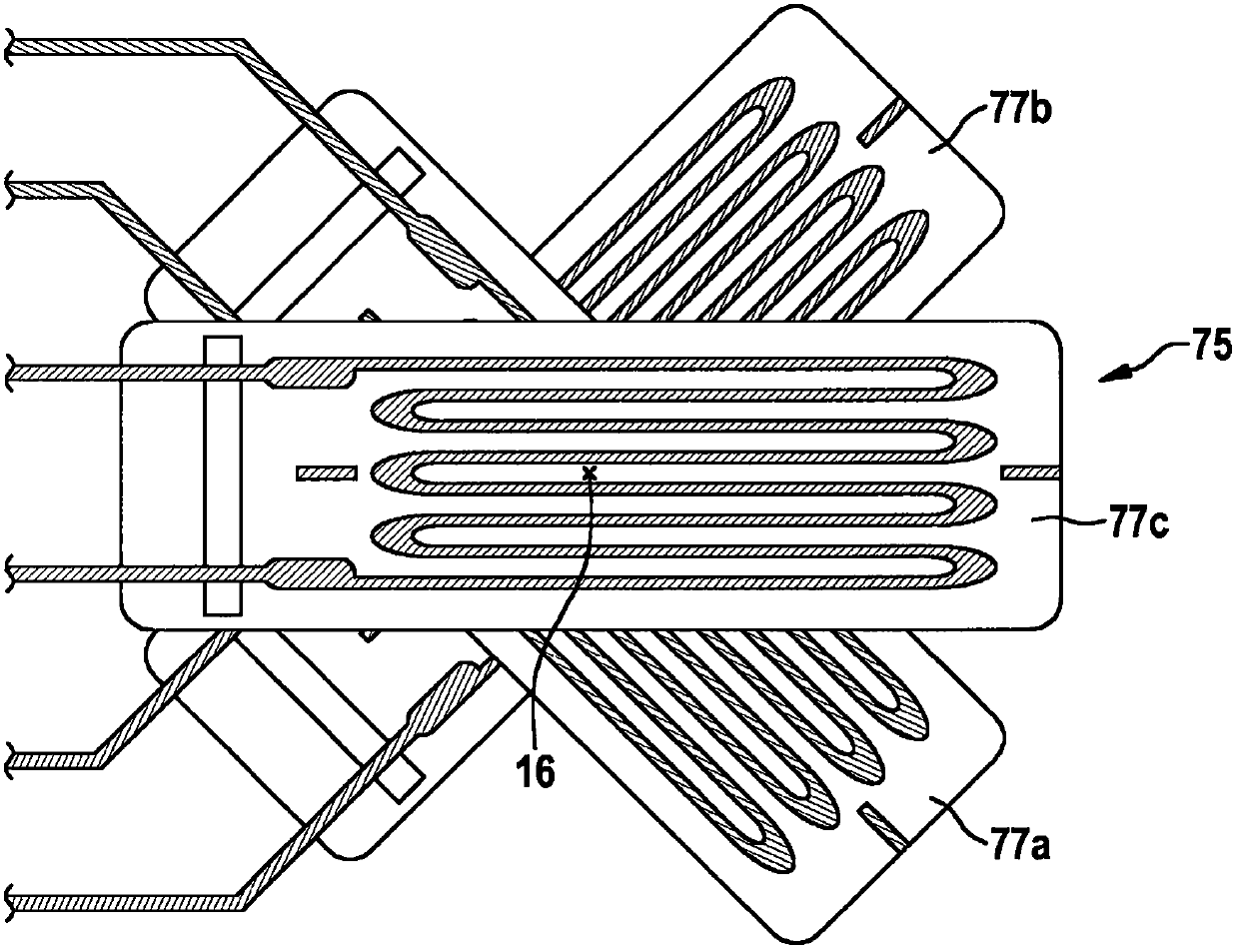

[0021] figure 1 The illustrated fuel injector 10 according to the invention is a component part of a common rail injection system for injecting fuel into a combustion chamber, in particular of a self-igniting internal combustion engine. The fuel injector 10 has an injector housing 11 which includes a nozzle body 12 on the side facing the not shown combustion chamber of the internal combustion engine. The cylindrical nozzle body 12 has a recess 13 in which the nozzle needle 15 is arranged movable up and down along the longitudinal axis 16 of the injector housing 11 in order to be closed or open on the bottom or in the wall of the nozzle body 12 The injection opening 17.

[0022] The side of the recess 13 of the nozzle body 12 facing away from the injection opening 17 is closed by a valve block 18 such that the recess 13 forms a high-pressure chamber 20 or high-pressure region for the fuel. The high-pressure chamber 20 is connected in particular to a storage element 23 configu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com