A main pump support device for a large-scale nuclear-grade main pump test bench

A technology of supporting device and main pump, applied in pump testing, liquid variable capacity machinery, machine/engine, etc., can solve problems such as difficult design, installation accuracy of the main pump that plagues the use of the bench, inconsistent length of the main pipeline, etc. The effect of ensuring stability, ensuring strength and safety, and ensuring contact stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

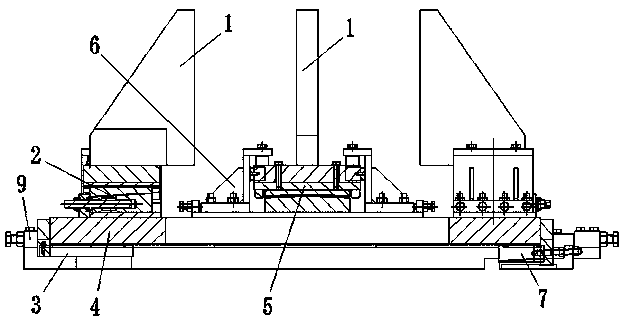

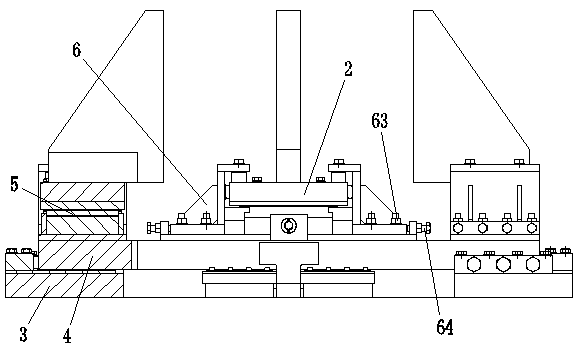

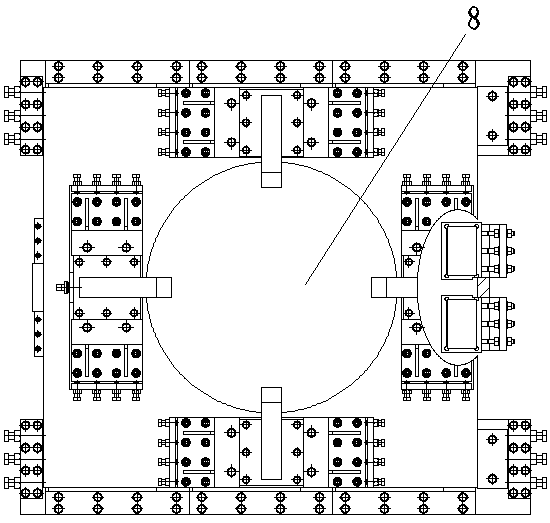

[0065] see Figure 8-Figure 10 , the pump casing A and the pump casing B are installed at both ends of the pipeline. There are two in the present invention, and the reference signs are C and D. The main pump support device C and the main pump support device D are installed on the steel structure platform. The main pump on the pump casing plays a supporting role. When testing the main pump A', the main pump supporting device C is fixed, and the relevant limit mechanism of the main pump supporting device D is loosened, so that it can freely expand and rotate at a small angle when the temperature of the pipeline system rises; when testing the main pump B' , the main pump support device D is fixed, and the relevant limit mechanism of the main pump support device C is loosened, so that it can expand freely and rotate at a small angle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com