Overload protection device for multi-axial force sensor

A multi-axis force sensor and overload protection technology, applied in the field of sensors, can solve the problems of difficulty in ensuring the strength and stiffness of the overload device with clearance accuracy, difficulty in ensuring the design accuracy of the overload protection method, and limiting the use effect and application of the multi-axis force sensor. To achieve the effect of simple shape, reliable overload protection and good manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

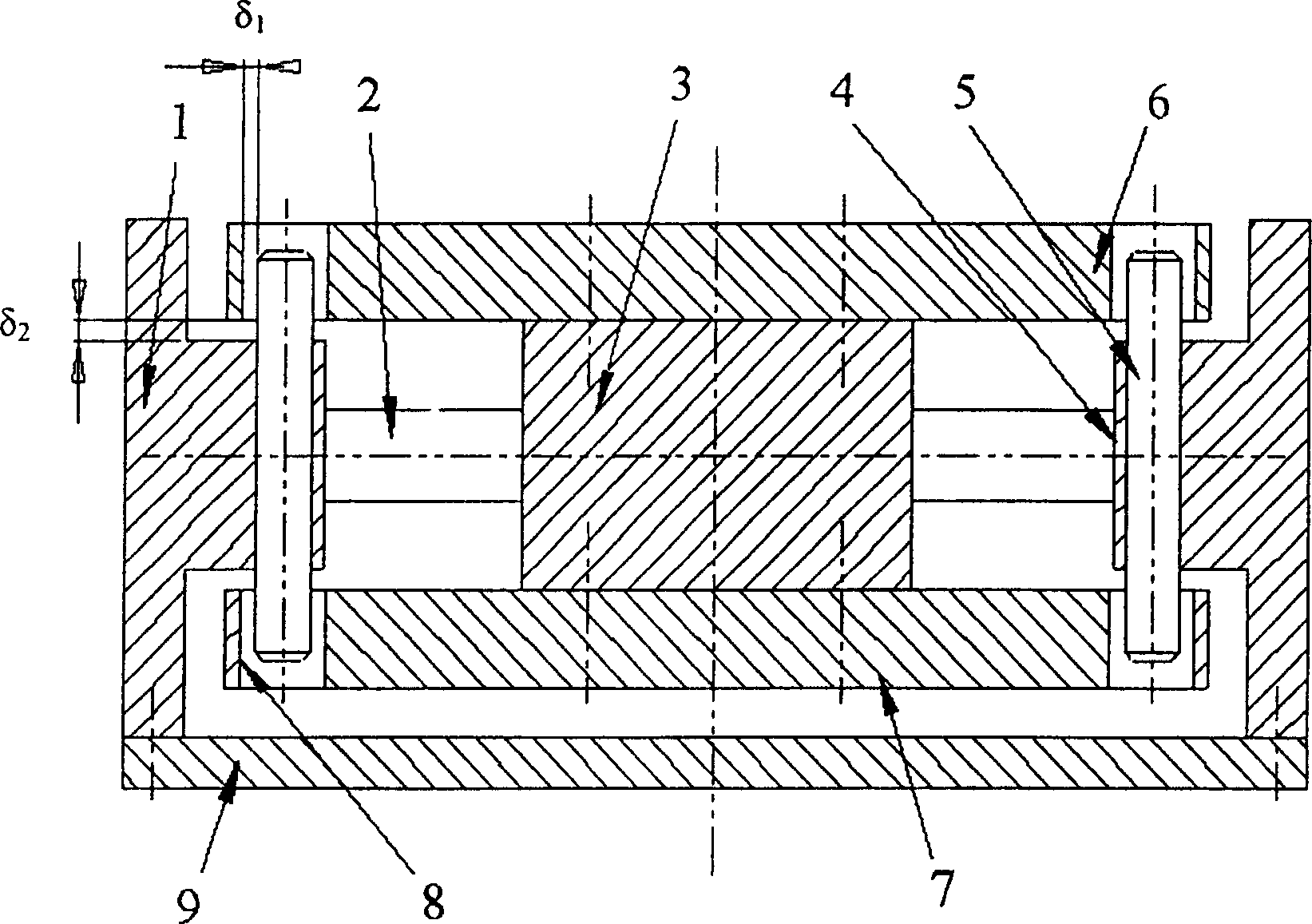

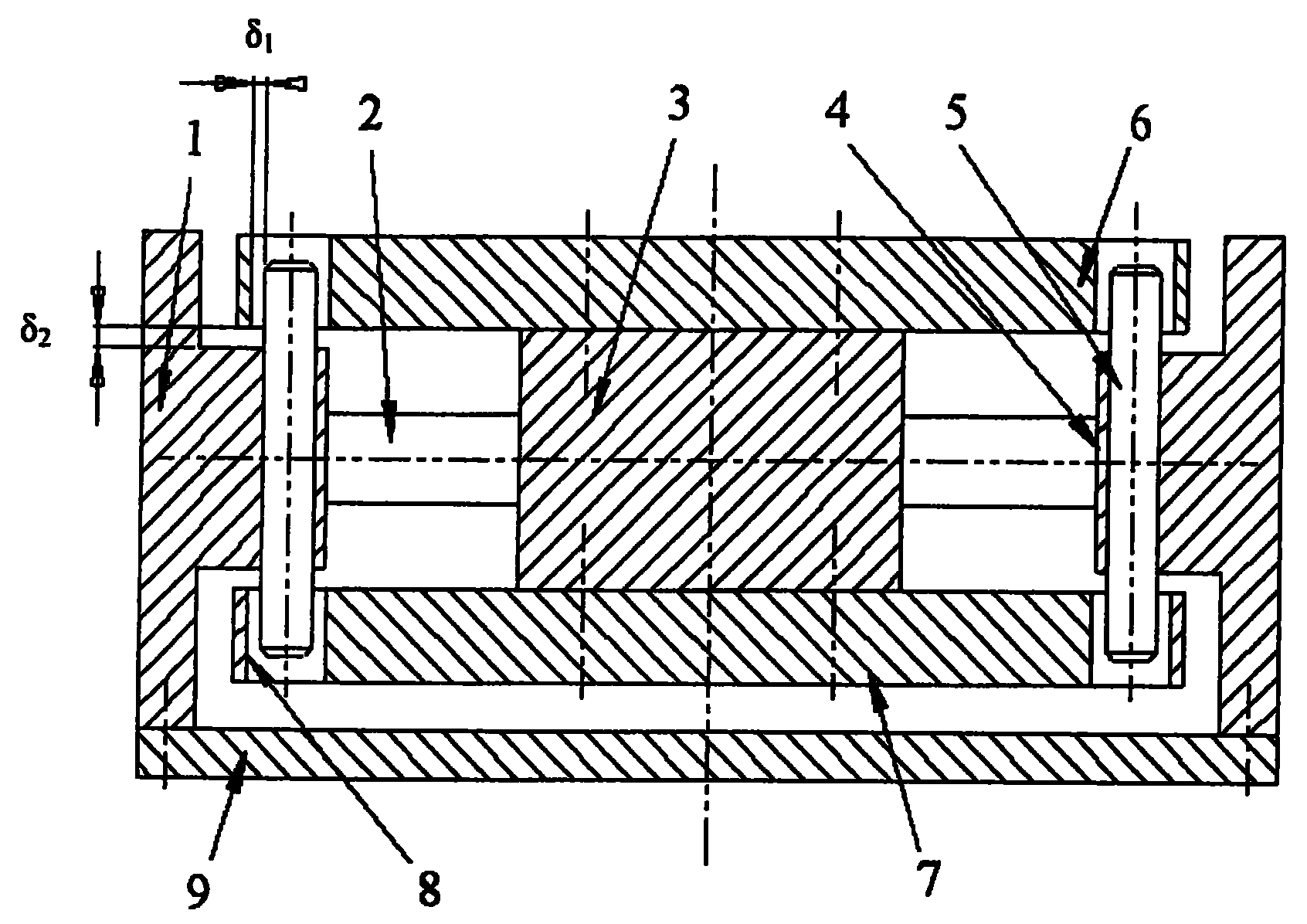

[0011] Referring to the accompanying drawings, in this embodiment, the upper end cover 6 and the lower end cover 7 are fixedly arranged on the end surface of the supporting platform 3 of the elastic body 2 provided with strain gauges, and the upper end cover 6, the lower end cover 7 and the supporting platform 3 are in the shape of "work". font, the upper end cover 6, the lower end cover 7 and the support platform 3 are connected with screws.

[0012] There is also a limit boss 4 located between the upper end cover 6 and the lower end cover 7, which forms an axial limit for the upper end cover 6 and the lower end cover 7 respectively, and there is an axial limit gap δ 2 .

[0013] The limit pin 5 fixed on the limit boss 4 is matched with the limit pin hole 8 on the upper end cover 6 and the lower end cover 7 at the corresponding position with a radial clearance, and there is a limit side clearance δ 1 , the limit pin 5 is parallel to the axis of the supporting platform 3 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com