Device and method for measuring electrode position of ore heating furnace

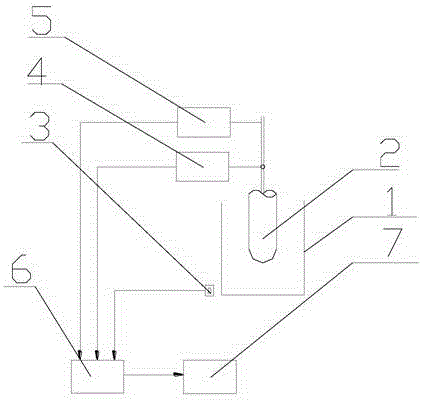

A technology of measuring device and measuring method, which is applied in the direction of electromagnetic measuring device, electric/magnetic position measuring, measuring device, etc., can solve the problem that the electrode of submerged arc furnace is difficult to locate accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

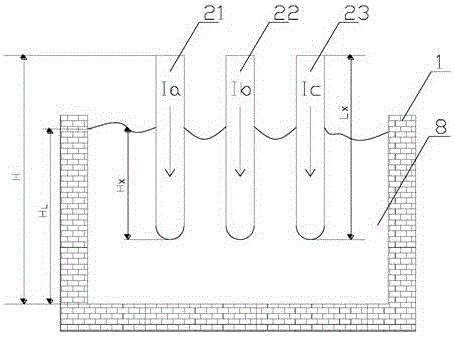

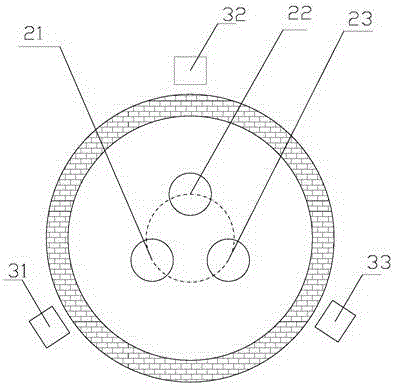

[0054] This embodiment provides a method for measuring the position of an electrode of a submerged arc furnace, which is implemented for the device for measuring the position of an electrode of a submerged arc furnace in the above embodiment.

[0055] The specific process is as follows:

[0056] Measure the distance H from the top of the electrode to the bottom of the furnace, and the depth H of the smelted material L , the horizontal distance R between the magnetic field sensor and the central axis of the phase electrode, the electrode current measurement component measures the phase electrode current I, and obtains the horizontal magnetic field intensity B generated by the phase electrode current, and the controller according to

[0057]

[0058]

[0059] solve L X ,

[0060] where L X is the electrode length, μ 0 is the vacuum magnetic permeability, α is the angle formed by the connection line between the lowest point of the electrode and the magnetic field sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com