A near-infrared region mechanoluminescence phosphor and preparation method thereof

A near-infrared region, electroluminescence technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problem that luminescent phosphors are not reported and limited to ultraviolet light, blue light, green light to red light, etc., and achieve the preparation process. Simple, low cost, easy to mass-produce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

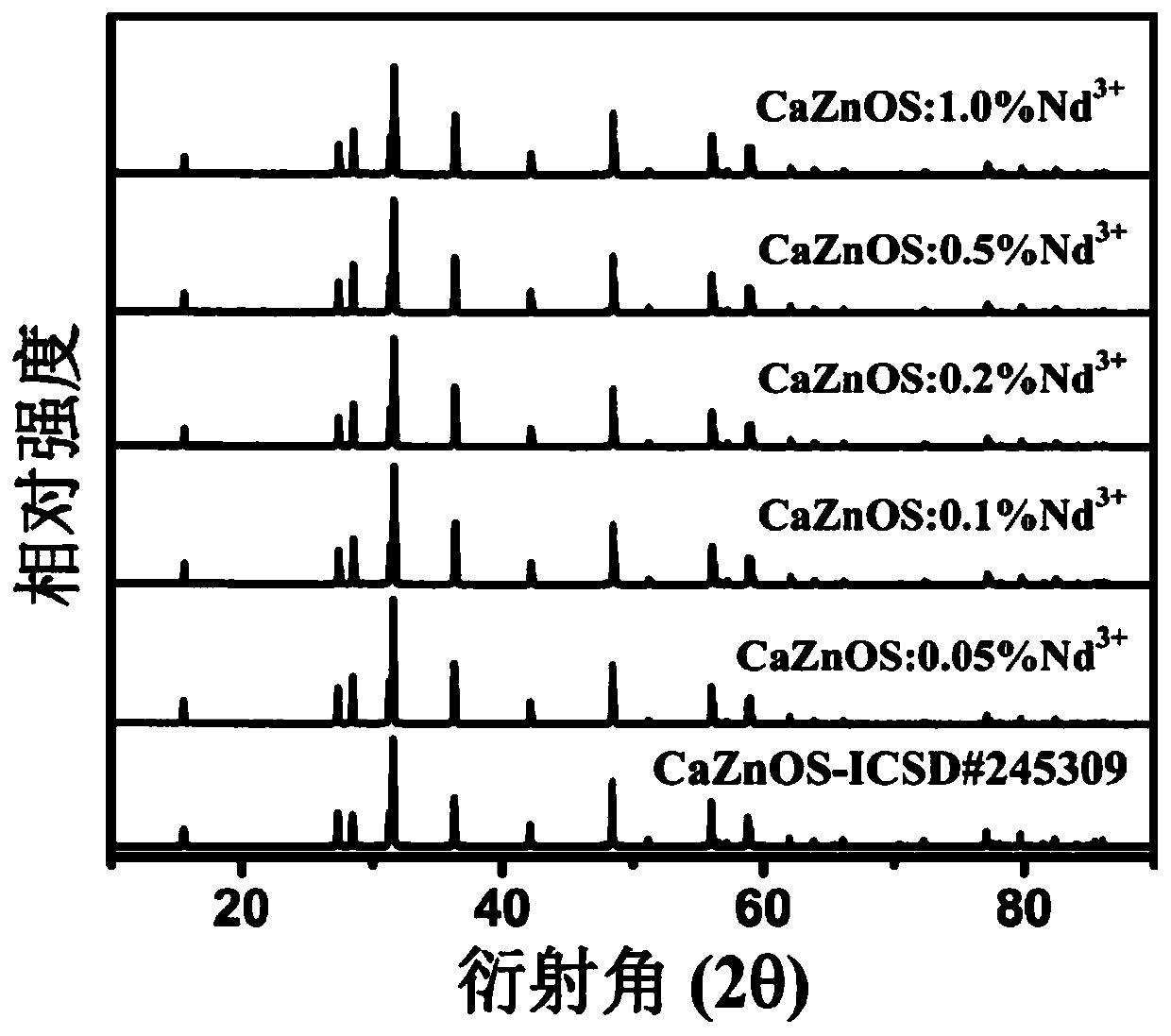

[0033] Choose calcium carbonate, zinc sulfide, and neodymium oxide as raw materials, according to the molar ratio of each element Ca:Zn:S:Nd=1-x:1:1:x, respectively weigh three kinds of compound raw materials, a total of five groups, for example Down:

[0034] (1) Ca:Zn:S:Nd=0.999:1:1:0.001, corresponding to x=0.10%;

[0035] (2) Ca:Zn:S:Nd=0.998:1:1:0.002, corresponding to x=0.20%;

[0036] (3) Ca:Zn:S:Nd=0.997:1:1:0.003, corresponding to x=0.30%;

[0037] (4) Ca:Zn:S:Nd=0.995:1:1:0.005, corresponding to x=0.50%;

[0038] (5) Ca:Zn:S:Nd=0.990:1:1:0.010, corresponding to x=1.00%;

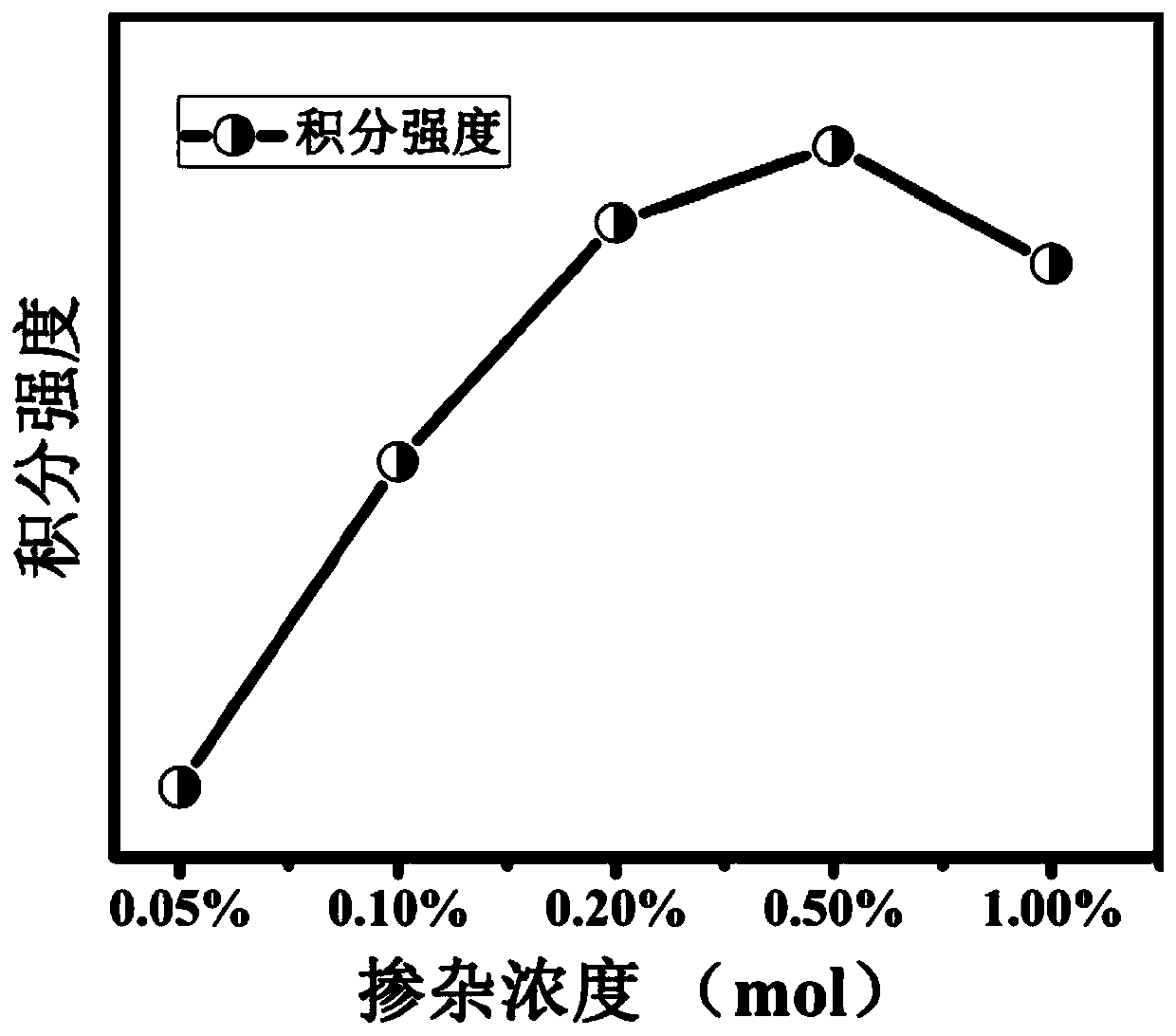

[0039] Control the total weight of the mixture to be 5g, grind 5g of mixed raw materials evenly, put them into a corundum crucible, then place the crucible in a corundum boat, push the corundum boat into a tube furnace, and roast at 1100°C for 3 hours under a nitrogen atmosphere. Cool naturally with the furnace to get a series of near-infrared mechanoluminescent phosphors with doping concentrati...

Embodiment 2

[0045] Select calcium oxide, zinc sulfide and neodymium nitrate as raw materials, weigh a certain amount of the above raw materials according to the molar ratio Ca:Zn:S:Nd=0.995:1:1:0.005, and after the raw materials are ground and mixed, take a part and add PVA Carry out granulation, take 5g of the raw material after granulation and carry out tabletting, adopt semi-automatic tabletting machine to keep 2min under 10Mpa, obtain the cylindrical flake of 25 * 10mm. The flakes were placed in a corundum boat and baked at 1100°C for 4 hours in a vacuum atmosphere; powder X-ray diffraction analysis showed that it was a CaZnOS crystal phase.

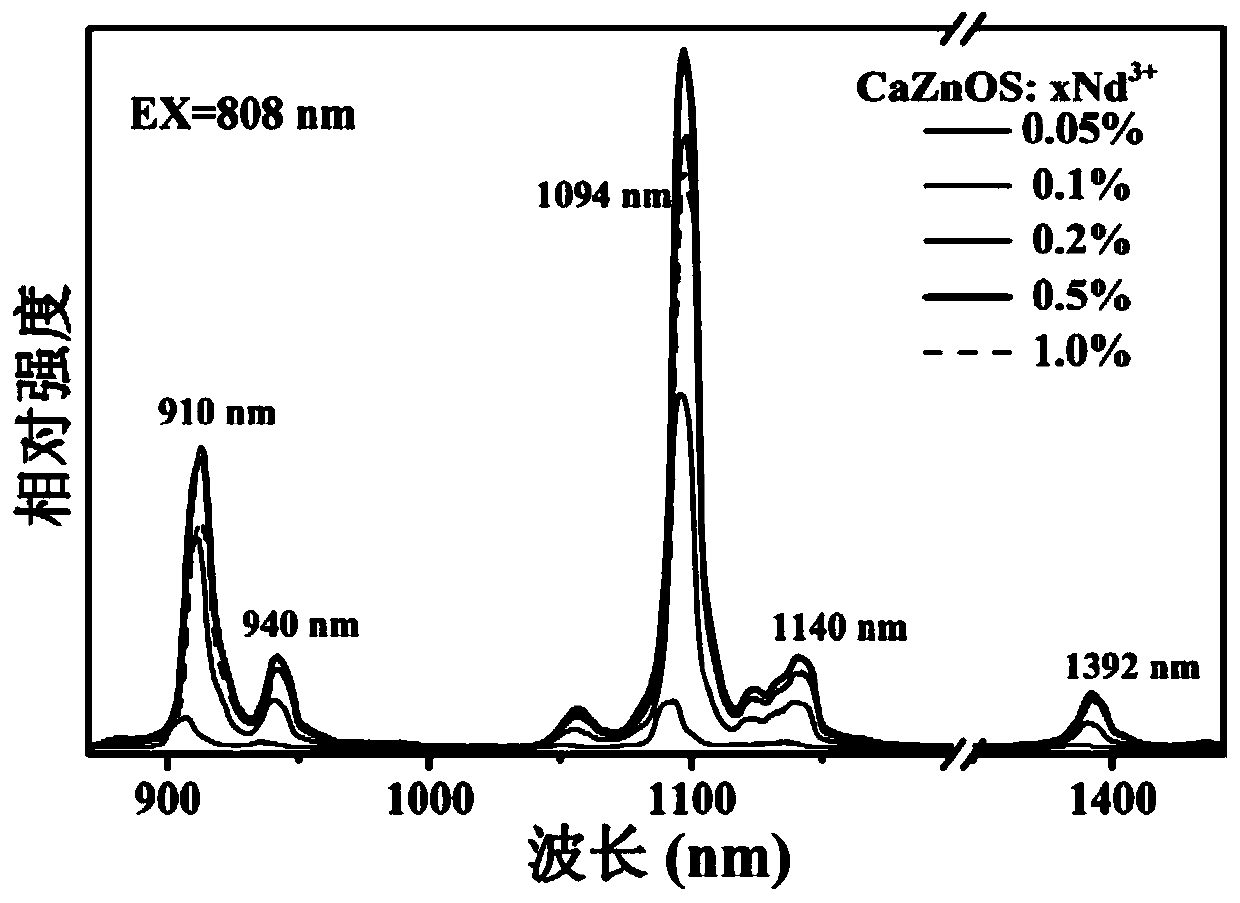

[0046] Calcined CaZnOS:0.5%Nd 3+ The sample is fixed on the sample stage, rubbed with a corundum rod with a sharp tip, and a spectrometer is used to collect the luminescent signal of the sample under friction excitation. Keep the distance between the rubbing tip and the fiber optic probe at 8mm. When performing triboluminescence experiments in...

Embodiment 3

[0048] Select calcium hydroxide, zinc sulfide, and neodymium hydroxide as raw materials, and weigh a certain amount of the above raw materials according to the molar ratio Ca:Zn:S:Nd=0.995:1:1:0.005. After the raw materials are ground and mixed, take an appropriate amount into a corundum crucible, then place the crucible in a corundum boat, push the corundum boat into a tube furnace, bake at 1000 ° C for 8 hours in an argon atmosphere, and cool naturally with the furnace. The obtained sample can be ground evenly to obtain near-infrared region mechanoluminescent phosphor CaZnOS:0.5%Nd 3+ . The obtained phosphor powder and transparent epoxy resin were mixed evenly at a mass ratio of 5:1, and cured at room temperature for 8 hours to obtain a cylindrical phosphor resin composite material with a size of 25×15 mm. The WEW-600 microcomputer-controlled universal testing machine was used to carry out the pressure luminescence test, and the pressure range was controlled from 0N to 5000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com