Sealing gasket for piping systems and its manufacturing process

一种密封垫圈、管道系统的技术,应用在发动机的密封、管子/管接头/管件、法兰连接等方向,能够解决密封垫圈困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] First of all, it should be emphasized here that the following description will be based on a preferred embodiment of the invention. However, as will be apparent to those skilled in the art, the present invention is not limited to these particular embodiments.

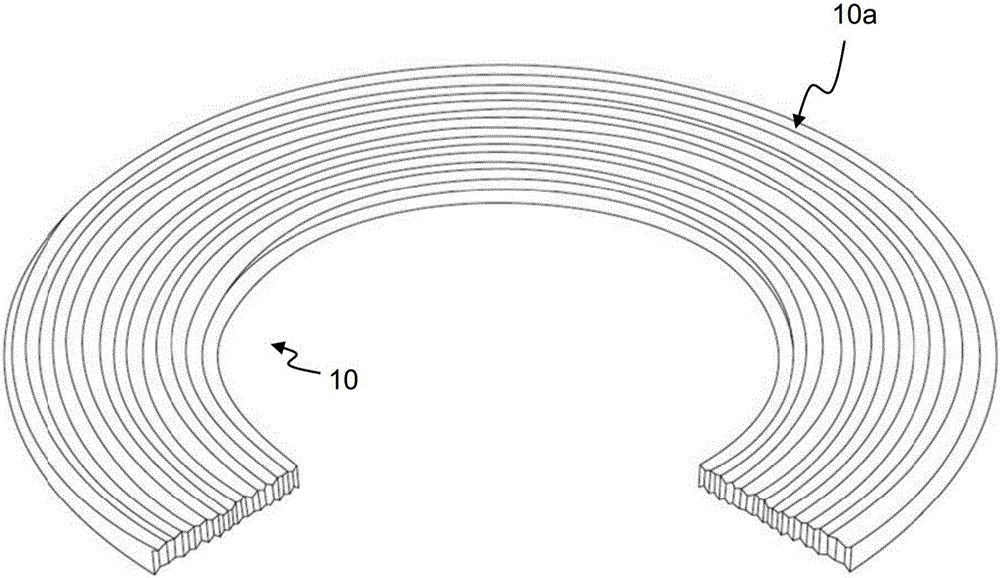

[0021] image 3 An elevational view of the core 10 of the sealing gasket according to a preferred embodiment of the present invention is shown. As can be seen, unlike prior art gaskets, the gasket according to the invention comprises a core 10 formed from a plurality of concentric metal rings 10a, each ring 10a having a substantially rectangular cross-section, wherein all rings The rectangular sections of 10a have the same height.

[0022] Preferably, the core 10 of the sealing gasket of the invention is formed by at least four concentric metal rings 10a.

[0023] Preferably, each concentric metal ring 10a has a square cross-section. Thus, all rings 10a have the same height and width, so that the core of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com