Fiber net sand cutting machine

A fiber mesh and frame technology, which is applied in the field of fiber mesh sand cutting machines, can solve the problems such as the knife teeth cannot go down, the fiber mesh is brought out, and the fiber mesh sand cannot be removed, and achieves a reasonable structure design and meets the leveling requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

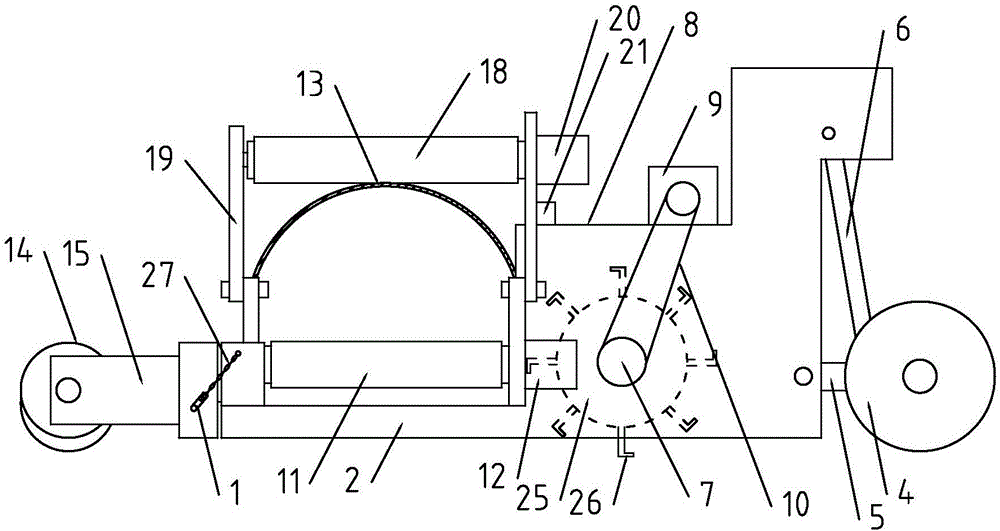

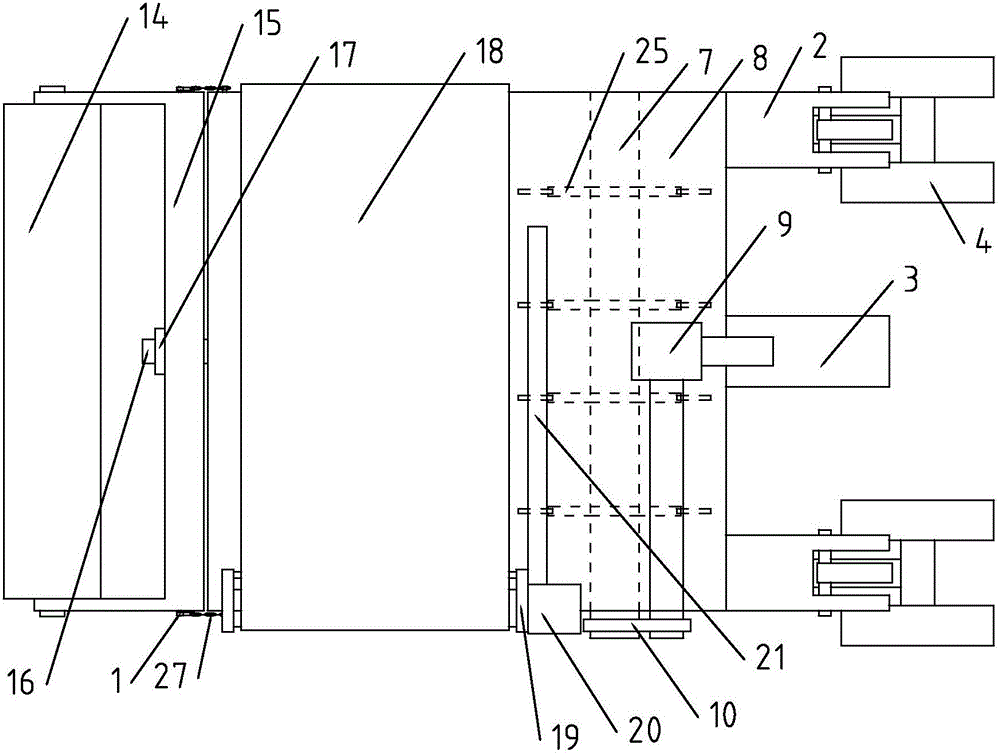

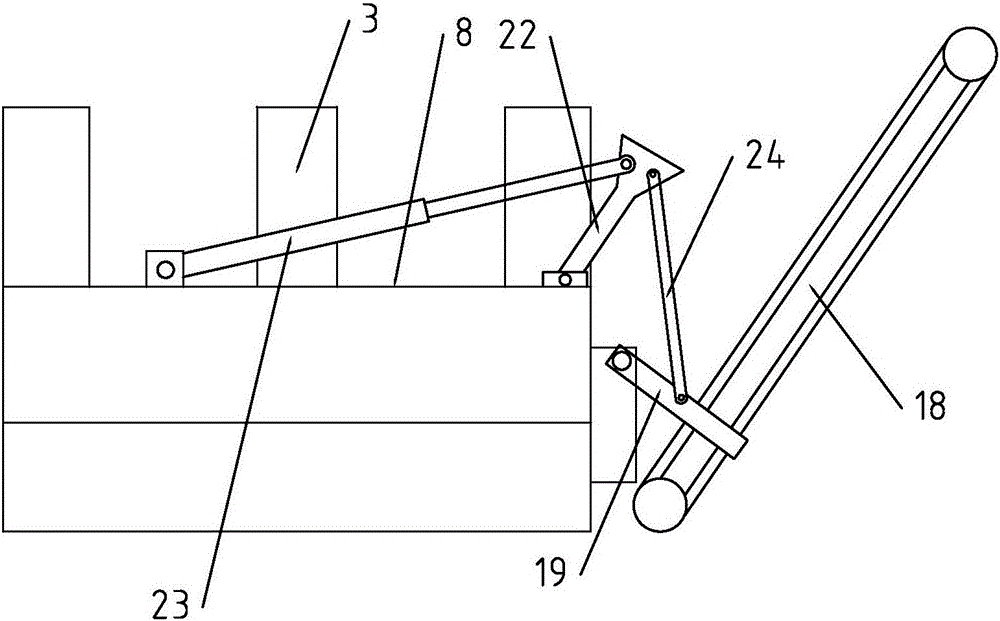

[0019] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0020] like Figure 1-3 As shown, the fiber net sand cutting machine includes a tractor body (not shown in the figure) and a sand cutting mechanism that is movable behind the tractor body. There is a suspension beam 3, and the sand cutting mechanism is movable on the tractor body through the suspension beam 3, and a ground wheel assembly is respectively arranged on both sides of the front part of the frame 2, and the ground wheel assembly includes a ground wheel 4, and the ground wheel 4 and The frame 2 is connected by the first connecting rod 5, one end of the first connecting rod 5 is fixedly connected with the rotating shaft of the ground wheel 4, the other end is hinged with the frame 2, and the cylinder bottom end of the first hydraulic cylinder 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com