Trophy Assembling Systems And Methods

A trophy and component technology, applied in the trophy assembly system and its field, can solve the problems of immutable, not cost-effective, and not allowing users to mix and match

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

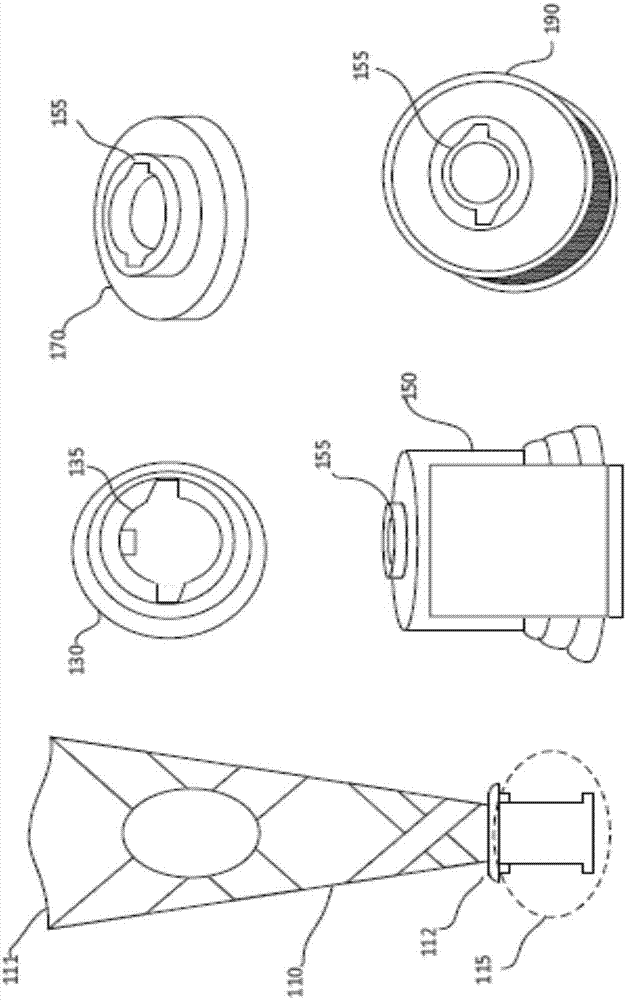

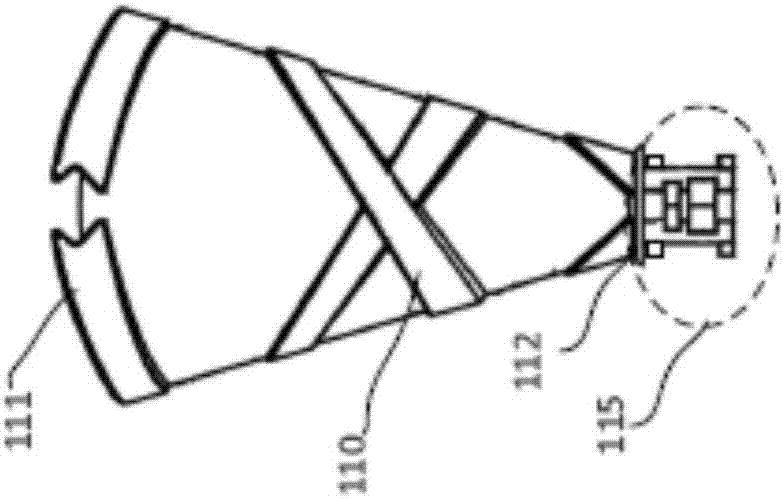

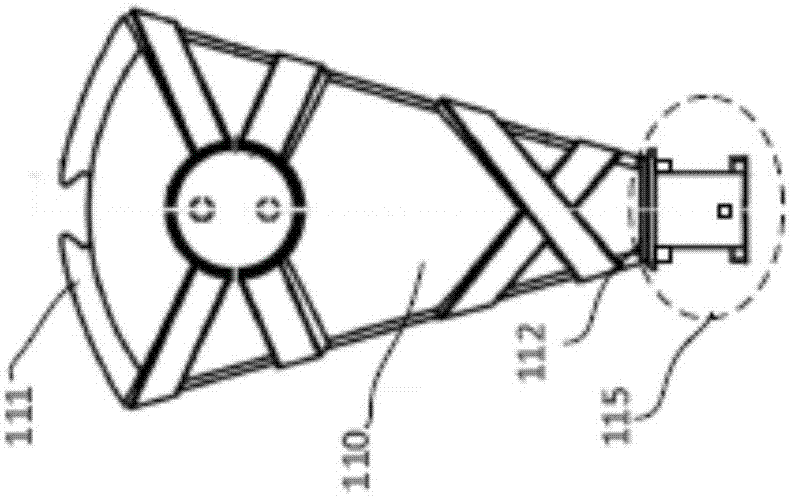

[0018] Embodiments of the present disclosure generally relate to various fastening systems for assembling trophies and methods of assembling trophies. For example, fastening systems utilize locking mechanisms and / or fasteners to assemble trophies. In one embodiment, the locking mechanism includes at least one male and female connector. A male connector may for example be applied to a first component of a trophy and a female connector may eg be applied to a second component of a trophy. The male connector includes a first configuration that mates with a second configuration of the female connector. For example, when a male connector mates with a female connector, the male connector may engage the female connector through a twisting or rotational movement to provide a secure connection between the various components of the trophy. As will be described in this disclosure, the fastening system allows a user to mix and match new or existing trophy components of various sizes and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com