Printing device, printing method

A technology of printing device and conveying direction, which is applied in printing, transfer material, and letter spacing mechanism, etc., can solve problems such as low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

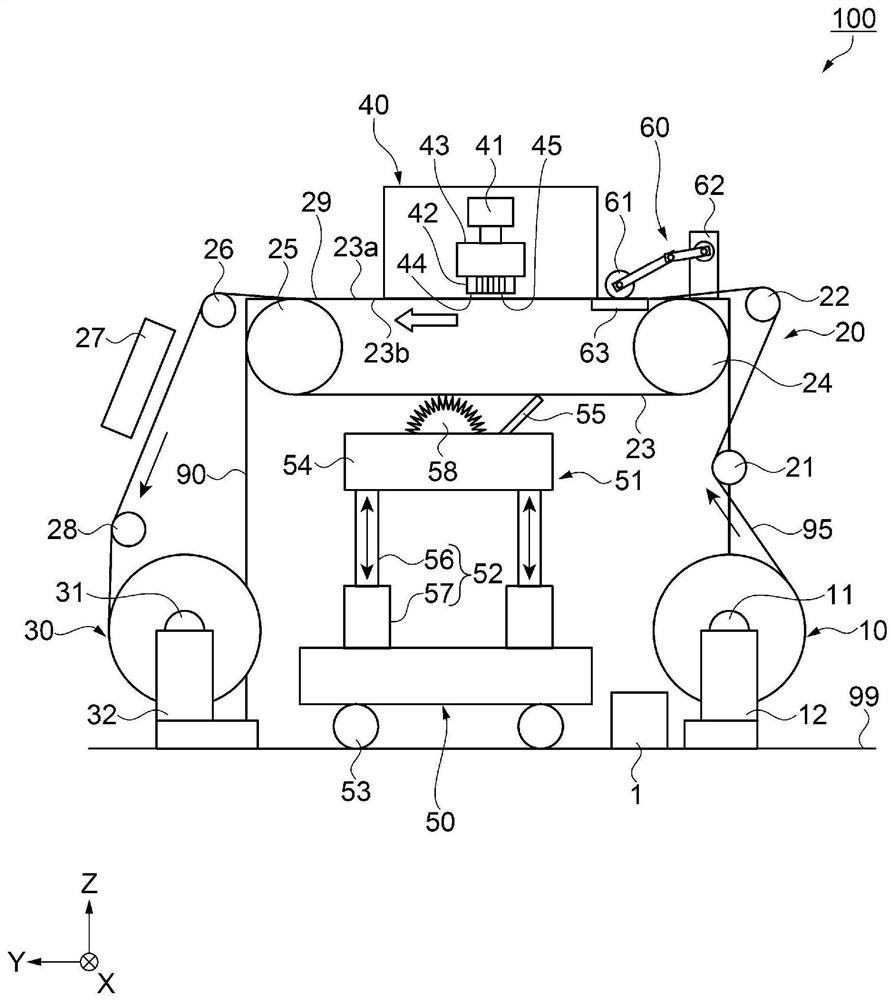

[0030] Outline configuration of printing device

[0031] figure 1 It is a schematic diagram showing a schematic overall configuration of the printing apparatus according to the embodiment. First, refer to figure 1 , the schematic configuration of the printing apparatus 100 according to this embodiment will be described. In addition, in this embodiment, the inkjet type printing apparatus 100 which performs printing on the recording medium 95 by forming an image etc. on the recording medium 95 is taken as an example and demonstrated.

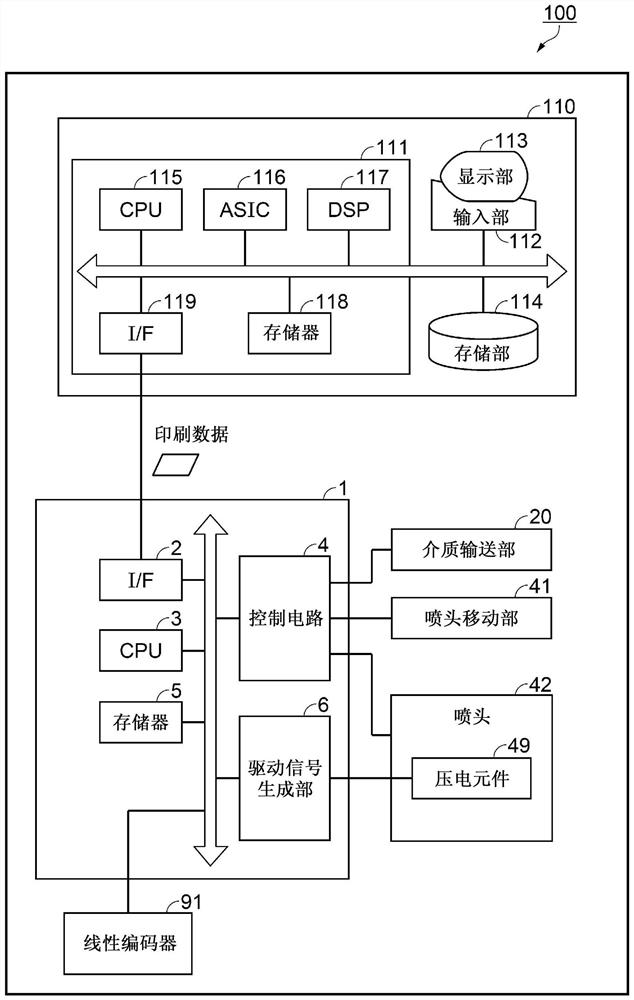

[0032] Such as figure 1 As shown, the printing device 100 includes: a medium conveying unit 20 , a medium adhering unit 60 , a printing unit 40 , a drying unit 27 , a cleaning unit 50 , and the like. Furthermore, it has the control part 1 which controls each said part. Each part of the printing device 100 is attached to the frame part 90 . In addition, the printing apparatus 100 has an image processing apparatus 110 (refer to image 3 ).

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com