Inkjet printing apparatus

An inkjet printing and ink technology, applied in printing and other directions, can solve the problems of decreased printing quality, inability to print, clogging, etc., and achieve the effect of suppressing inability to print

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

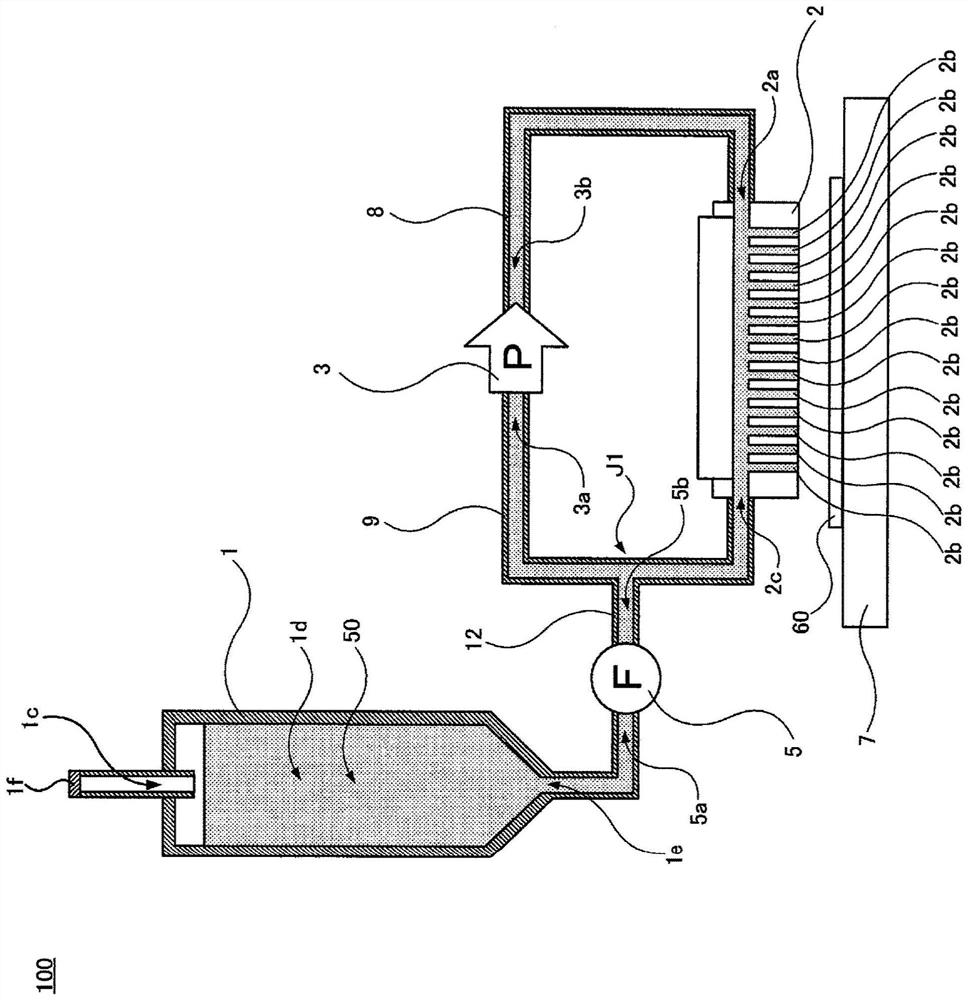

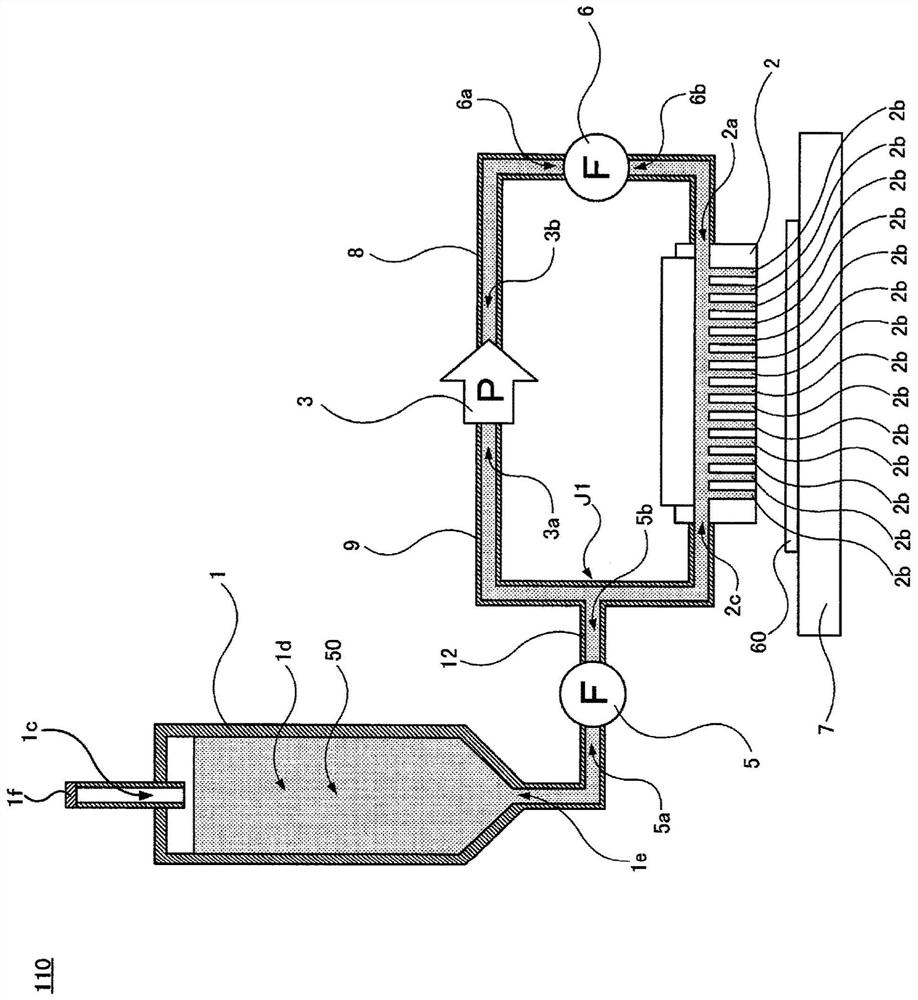

[0071] figure 1 The inkjet printing apparatus 100 of the first embodiment is shown. in, figure 1 It is an explanatory diagram of the inkjet printing apparatus 100 .

[0072] Hereinafter, first, the outline of the inkjet printing apparatus 100 will be described, and then each component will be described in detail.

[0073] It should be noted that the important features of the inkjet printing apparatus 100 are that (a) the first filter 5 is provided in the supply pipe 12 described later, and (b) the second head circulation pipe 9 described later is not provided. filter.

[0074] The inkjet printing device 100 includes a first ink tank 1 , a head 2 , a first pump 3 , a first filter 5 , and a stage 7 . It should be noted that, in figure 1 The ink 50 and the object to be printed 60 are also shown in FIG.

[0075] The first ink tank 1 includes a third ink supply port 1c, a first ink storage portion 1d, and a first ink outlet 1e. In addition, the third ink supply port 1c is...

Deformed example 2

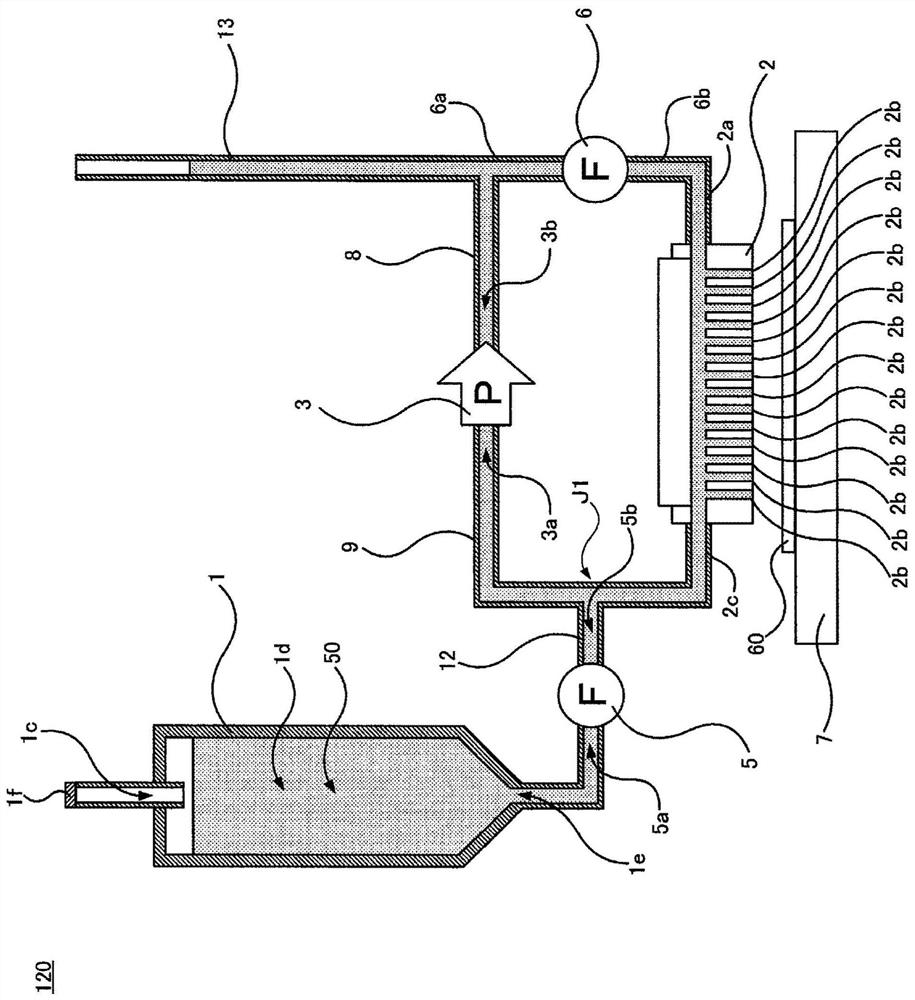

[0119] (Modification 2 of the first embodiment: inkjet printing device 120 )

[0120] image 3 An inkjet printing device 120 according to Modification 2 of the first embodiment is shown. The inkjet printing apparatus 120 is further modified from the inkjet printing apparatus 110 of Modification 1. FIG.

[0121] In the inkjet printing device 120 , an air-opening degassing channel 13 extending vertically upward is provided between the first pump 3 and the second filter 6 of the first head circulation piping 8 of the inkjet printing device 110 . The inkjet printing device 120 can remove unnecessary air bubbles from the ink flowing through the first head circulation piping 8 through the degassing channel 13 .

[0122] It should be noted that the upper surface of the ink contained in the degassing channel 13 is kept within a fixed range by the balance between the self-weight of the ink and the pressure of the ink ejected by the first pump 3 . Therefore, ink does not overflow fro...

no. 2 approach

[0134] Figure 6 The inkjet printing apparatus 200 of the second embodiment is shown. in, Figure 6It is an explanatory diagram of the inkjet printing apparatus 200 .

[0135] The important features of the inkjet printing device 200 are: (c) the first filter 5 is provided in the supply pipe 12; The flow path resistance of the first suction port 3a, that is, the second flow path resistance is set to 10 times the flow path resistance from the discharge port 2c of the nozzle 2 to the first suction port 3a of the first pump 3, that is, the first flow path resistance. above.

[0136] In addition, in this specification, the flow path resistance of the flow path provided with a filter means the flow path resistance in the state containing a filter.

[0137] In above-mentioned experiment 1, when all setting filter (sample 1) between the shower head 2 and the first connection point J1 of piping 12 and the second shower head circulation piping 9 for supplying, the ink from the showe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com