Spiral shaver head

A razor and spiral technology, applied in the field of electric shaver heads, can solve the problems of not so clean shaving effect, pulling beards, etc., to achieve clean shaving effect, overcome vibration, and avoid pulling beards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

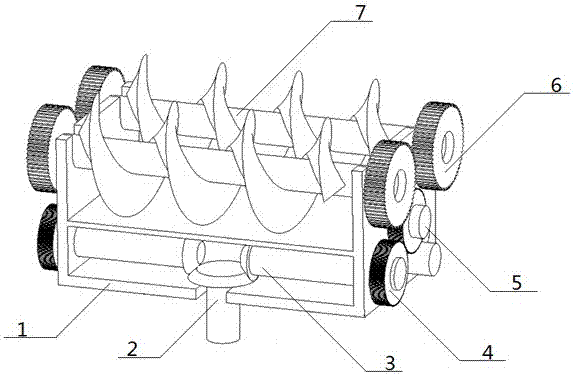

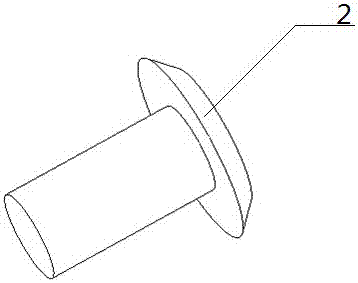

[0016] Such as figure 1 , figure 2 As shown, the present invention is a spiral shaver head. When the shaver is working, the rechargeable battery provides power to the input bevel gear shaft 2, and its high-speed rotation is output in two parts, and one part is transmitted to the driven bevel gear 4. The driven bevel gear 4 is transmitted through the driven bevel gear shaft and several cylindrical gears 6, and finally output by the helical cutter 8; in the transmission process, multiple cylindrical gears 6 can be designed, which has two purposes: the first purpose The purpose is to ensure that the two helical cutters 8 turn in opposite directions, and the second purpose is to obtain a suitable rotation speed, so engineers can increase or decrease the number of spur gears 6 as needed during specific implementation. In the current figure 1 Among them, there are three cylindrical gears 6 to transmit the power from the motor to the screw cutter 7. Of course, this process requires...

Embodiment 2

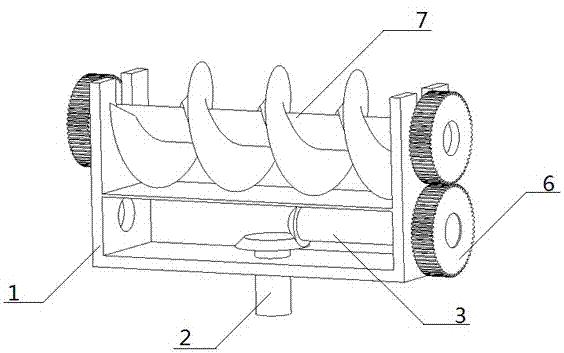

[0019] Such as Figure 4 As shown, it includes a driving bevel gear 3, a driven bevel gear 4, two cylindrical gears 6, a helical cutter 8, and a single helical support 9. This structure has the characteristics of lightness, flexibility, and long shaving time; When the shaver is working, the rechargeable battery provides power to the input bevel gear shaft 2, and its high-speed rotation is output in two parts, one part is transmitted to the driven bevel gear 4, and the driven bevel gear 4 passes through the driven bevel gear shaft and several cylindrical gears 6 transmission, finally output by the spiral knife 8;.

[0020] At present, these two schemes use the razor of the spiral razor head, and its thin mesh cover is fixed and connected with the bracket 1. Of course, an elastic connection shaft can also be designed between the cylindrical gear 6 and the helical cutter 8. In this way, the thin mesh cover can translate to the motor along the direction of the active bevel gear s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com